Quality Assurance

At GREFEE, we concentrate on every detail of the products. Good quality is the foundation that we live.

- FQC: Final Quality Control. Check product quality after all process completed.

- IQC: Incoming Quality Control. Ensure the quality of the purchased materials.

- QE:Quality Engineers seek to test, control and improve process to improve product quality from prototype quality control to production.

- IPQC: InPut Process Quality Control. Quality control from production to packing process, adopting circular inspection between every procedure in production for quality testing.

- OQC: Outgoing Quality Control. It’s a all-side inspection to ensure quality as customer required after parts delivered.

GREFEE’s QC team has rich experience in quality controlling. Before production, our QC engineers will set inspection standards for products. In the process of production, we’ll do spot checking or full inspection with following ISO standards. After production, we’ll fully inspect every part before delivery. Quality inspection process:

Material incoming inspection

Inspect and record all materials before production, to ensure the reality of materials.

Process inspection

In production process, arrange FAL(first item inspection) for every step, and checked by managers from engineering and QC departments.

Warehouse inspection

All products are 100% inspected before put into warehouse.

Pre-shipment inspection

Inspect parts again before shipping, record, and attach delivery report.

Equipment inspection

Inspect, revise, and identify QC equipments regularly.

Comprehensive quality control

High quality products require excellent technical team and advanced facilities. At GREFEE, we’re fully equipped with varied advanced inspection advices to check and test raw materials, product size, appearance, and function. To ensure high quality, we proceed all projects in following steps.

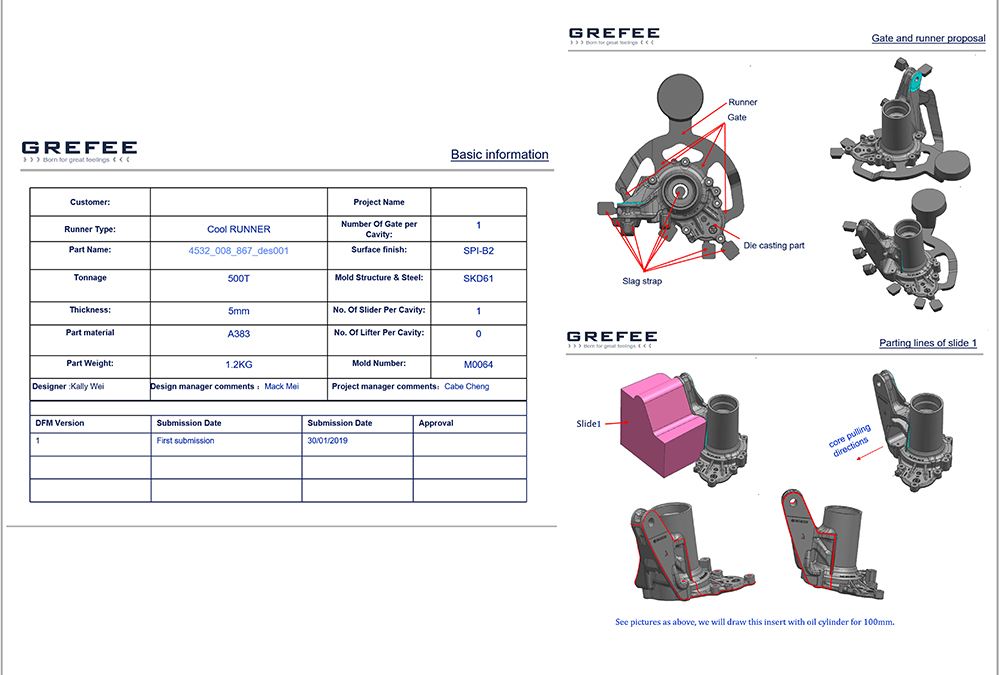

Pre-production technical support

In early stage of cooperation, we’ll provide customers free assessments of projects and improving suggestion(DFM), such as materials, surface requirements, product and tool structures, process technologies, 3D & 2D drawings, and other details, and also assist customers to modify product designing.

Set project control plan:After confirm the finalized drawings and requirements of products, our project engineering team will set production plans according to the overall requirements of projects, including production operation standard, quality inspection standard(material inspection, dimension inspection, appearance inspection, performance testing…etc.) and packing standard, etc.

In Production

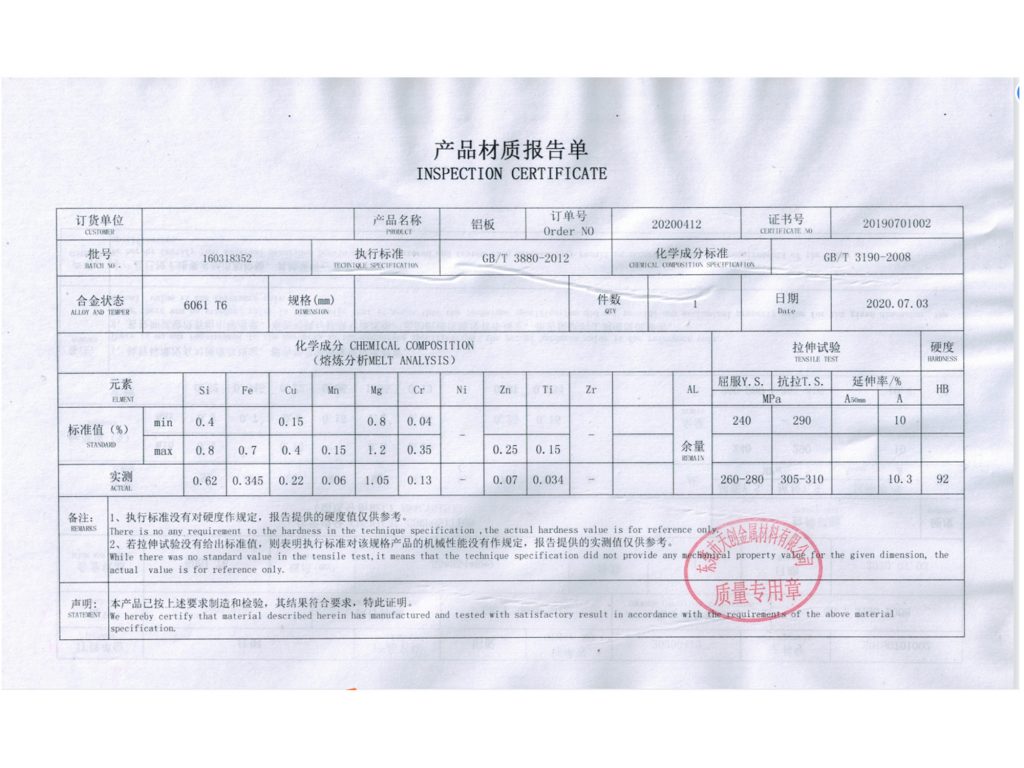

Authentic Materials:For all materials, we can provide certifications of material and heat treatment from raw material manufacturers, usually including material heat numbers, material trademarks, material size, mechanical property, chemical analysis, hardness, etc.

In-process quality control:For every project, our professional project engineers are responsible for project schedule, providing customer project schedule and photos every week, and also are responsible for quality together with QC and production departments.

GREFEE will set production and quality standards for every product based on ISO9001:2015, including FAI(first article inspection), IPQC(InPut Process Quality Control), AQL(acceptable quantity limit) and full inspection.

Pre-shipment Inspection

In GREFEE’s quality control system, QC engineers are involved in every step, and data are recorded for tracing in the future. For all projects, we provide customer QC reports for all inspection items, including part quantity, critical dimensions, threads & tolerances, thickness & depth, part appearance, and material property, to ensure all parts 100% qualified delivery.

Packing:To ensure the custom made parts not damaged in logistics process, we provide 5 layers of protection in packing process: 1. Steel components are sprayed with anti-rust painting. 2. Wrapping paper. 3. Pearl cotton. 4. Foam. 5. Packed in boxes or wooden cases. We’d like to make sure that our customers received the most high quality and beautiful parts.

ISO certification

GREFEE is certificated with ISO9001:2015, ISO14001:2015, ISO13485:2016, TIF16949, etc. However, we’re not satisfied with what we’ve already achieved. We’re still on the way to improve quality and service, lower down the cost, improve the workplace, and reduce environmental pollution.

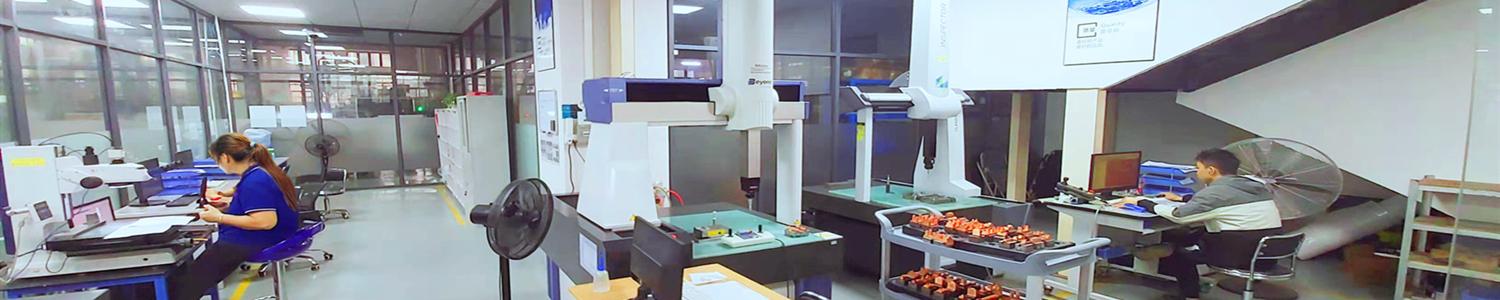

Inspection facilities in GREFEE

The three dimensional (CMM):

CMM is a measurement method of geometric elements, including point, line, surface, circle, sphere, cylinder, cone, etc. Based on coordinates of three-dimensional space, CMM can continually scan the part with complicated precise dimension, shape and tolerance, and the surface of high-precision geometric, and also mechanical parts with complicated shapes, and then achieve part inspection, shape measuring, and process control. CMM is widely used in industries of precision accessories, precision mould, precision manufacturing, military, aerospace and automobile making.

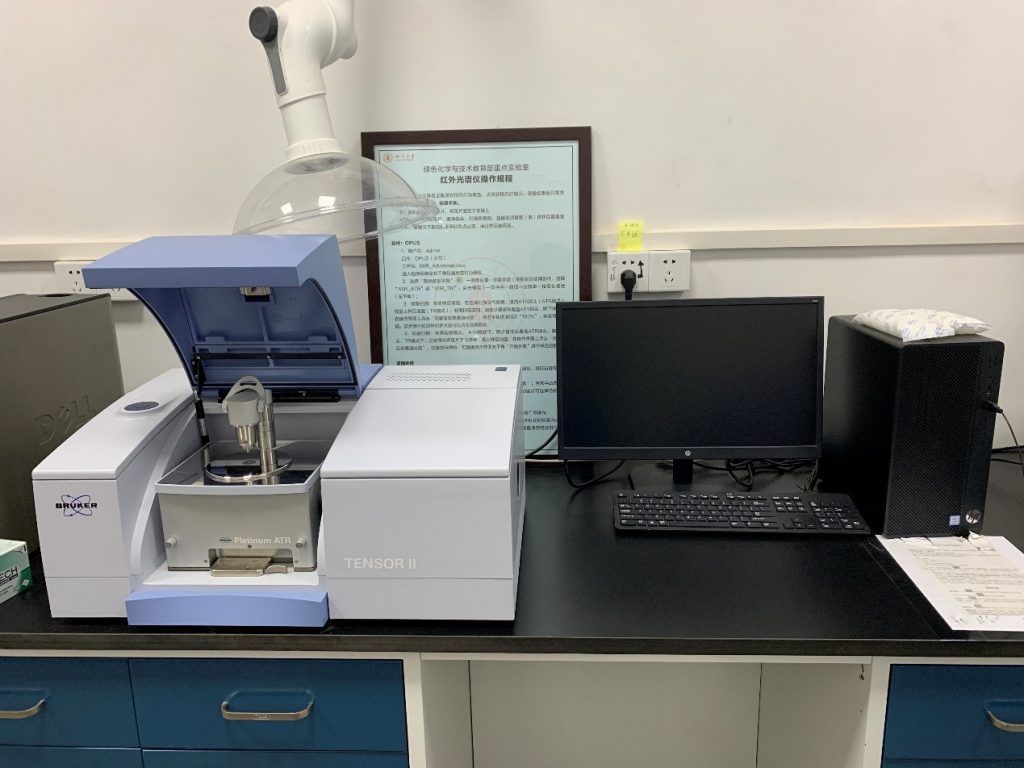

Spectrum analyzer:Spectrum analyzer can detect raw material ingredient in raw material feeding, it can quickly test the ingredient and element proportion of raw material, and its accuracy can meet laboratory requirements. It can identify the reality of material fast.

X ray:Mainly used for inspecting the air holes inside die casted parts.

2D image measuring:2D image measuring is based on CCD digital image, relying on computer screen measurement technology and powerful software ability of space geometry , It can read the displacement value of the optical ruler quickly, for the operator to make image contrast and measure, then quickly and intuitively distinguish the possible deviation of the measurement results. Generally it is used in simple hardware components and prototype model.

Roughness Tester:We use roughness tester to check the roughness of the part surface, to confirm whether the surface roughness is qualified, which avoid errors by artificial judgments.

Spectral photometric color measuring:Spectral photometric color measuring can simulate color difference under multiple lights.

Other inspection equipments:Besides, GREFEE has height gauge, hardness tester, all kinds of internal and external thread, micrometer, caliper, etc., All these inspection equipments are used for quality control testing, to make sure the product quality meet demands as customer required.

List of test equipment:

| Description | Range | Resolution | Outside Calibreation?(Y/N) | Outside Calibreation Frequency | Status | Divsion |

| Dial Calipers | 0-300mm | 0.01mm | Y | 1 YEAR | Normal | Quality department/Production department |

| Digital Caliper | 0-300mm | 0.01mm | Y | 1 YEAR | Normal | Quality department/Production department |

| Vernier caliper | 0-1000mm | 0.02mm | Y | 1 YEAR | Normal | Quality department/Production department |

| Digital inside micrometers | 6-100mm | 0.001mm | Y | 1 YEAR | Normal | Quality department/Production department |

| Digital outside micrometers | 0-100mm | 0.001mm | Y | 1 YEAR | Normal | Quality department/Production department |

| Pin gauge | 0.5-12mm | 0.01mm | N | / | Normal | Quality department/Production department |

| Block gauge | 1-200mm | 0.001mm | N | / | Normal | Quality department/Production department |

| Thickness Gauges | 0.02-1mm | 0.01mm | N | / | Normal | Quality department/Production department |

| Thickness Gauges | / | N | / | Normal | Quality department/Production department | |

| Treading Plug Gauges | / | N | / | Normal | Quality department/Production department | |

| Digital Depth Gauges | 0-200mm | 0.001mm | Y | 1 YEAR | Normal | Quality department/Production department |

| Digital Height Gauges | 0-50mm | 0.001mm | Y | 1 YEAR | Normal | Quality department/Production department |

| Height Gauges | 0-500mm | / | Y | 1 YEAR | Normal | Quality department/Production department |

| Profile Projector | 300*400mm | / | Y | 1 YEAR | Normal | Quality department |

| Metal material spectrograph | / | / | Y | 1 YEAR | Normal | Quality department |

| Hardness Tester | / | / | N | Normal | Quality department | |

| 2D measuring Projector | 300*400mm | / | Y | 1 YEAR | Normal | Quality department |

| CMM(The Three Dimensional) | 300*400mm | / | Y | 1 YEAR | Normal | Quality department |

| Surface Roughness Testers | / | / | Y | 1 YEAR | Normal | Quality department |

| Salt Spray Testers | / | / | N | / | Normal | Quality department |

| Leak test equipments | / | / | N | / | Normal | Quality department |

QC Report

For every order at GREFEE, we can provide complete QC report lists as customer required. Including but not limited to:

√ QC report

√ Full dimensional report

√ Material testing report

Certification

As a company which has more than 10ys experience in custom manufacturing, we provide the most commonly used certifications, including but not limited to:

√ ISO 9001:2015

√ ISO13485:2016

√ IATF16949:2016

Quality commitments

If customers find quality problems about the products after receive it, we’ll help solve at first time. If products still not work, we can re-make for free, and GREFEE covers the shipping cost. While sometimes customers are unwilling to accept re-making, GREFEE will refund full payment to our customers.

Try GREFEE now,for free

We keep your uploaded files confidential and secure.