Characteristics and Applications of the Nylon and Glass fiber Composites

Posted on : May25, 2022 By GREFEE

With the increasing needs for products with the rapid development of the processing industry, single texture materials cannot meet our requirements in multifaceted performance for materials. Use base material with different properties to process compound modification, providing mutual support of relative advantages. It can increase some specific properties without harming other properties of the compound material or is given new features to enlarge its application range. This has been an inevitable trend. Nylon & glass fiber is a common material for 3D printing, injection molding, and CNC parts due to their excellent properties. GREFEE has rich experience in the processing of fiber-reinforced nylon material. Start your project with GREFF now! Contact our engineering team for an instant quote.

Glass fiber is an inorganic nonmetallic material with excellent properties, including Inorganic salts such as silica, alumina, magnesium oxide, calcium oxide, and sodium oxide. The monofilament diameter is from a few microns to tens of microns, about 1/20~1/5 of a hair. Glass fiber often needs to be bundled in practical use. Each bundle of fiber precursor is made of hunger of fiber monofilaments. So like one of many compound materials in various fields of the national economy as reinforcement material, thermal and electrical insulation material.

1.The basic characteristics of glass fiber mainly include

(1). high tensile strength, small elongation rates (less than 3%)。

(2). large elasticity coefficient, good rigidity.

(3). inorganic fiber,not flammable and with good chemical resistance

(4). low absorption rate,transparent to light.

(5). great heat resistance and scale stability

(6). cheap price,it can melt into glass beads at high temperature.

Glass fiber, especially the comparison between glass fiber and organic fiber, has high-temperature resistance, incombustibility, corrosion resistance, electrical insulation, heat insulation, and sound insulation. However, it is brittle with low wear resistance. The glass fiber is widely applied to the electric insulation material, industrial filter material, anti-corrosion, moisture-proof, heat insulation, sound insulation, and shock absorption materials. Besides, it also can work as a reinforcing material, like reinforcement material, rubber reinforced gypsum, or cement.

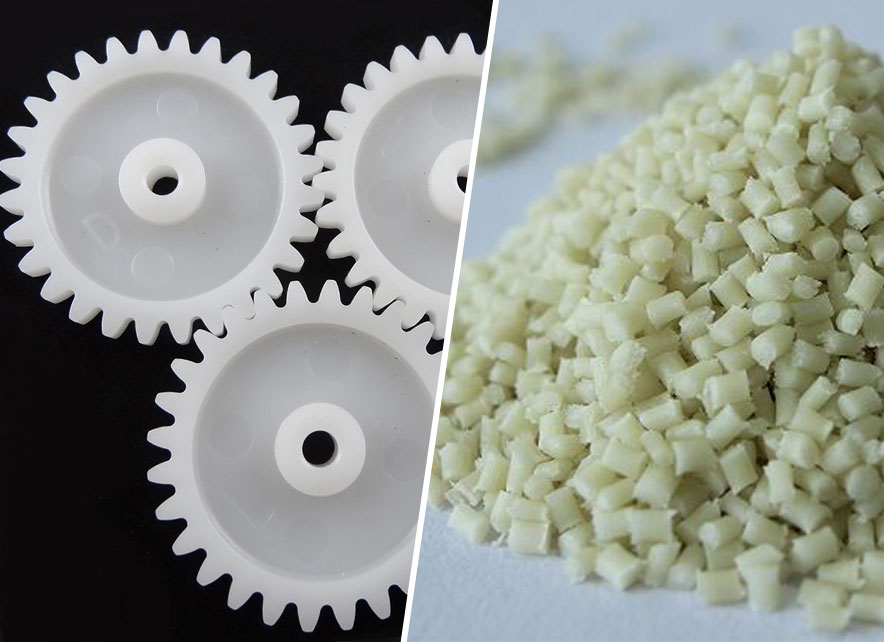

Nylon and glass fiber material is a plastic that obtained from the nylon resin containing a certain amount of glass fiber to reinforce.

Nylon glass fiber is a white powder. Compared with common plastic, its tensile strength and bending strength increase. The thermal deformation temperature and the material modulus are enhanced, too. The thermal deformation and shrinkage rate decreased, but surface roughness and impact strength lightly dropped. Based on the experiment, adding 30% artificial glass fiber in PA can improve the chemical properties, dimension stability, thermal resistance, and aging resistance, especially fatigue resistance is 2.5 times before.

Nylon glass fiber is mainly used in automobiles, household appliances, and consumer electronics. Its forming processing is similar to the unreinforced nylon. However, due to the increase in the viscosity of melts, the injection pressure and speed should be increased a bit. Increases the barrel temperature by 10~40 degrees. In the processing, the glass fiber will be oriented along the melt flow direction. So, the mechanical properties and dimensional stability of orientation direction.

2.Characteristics of nylon glass fiber material

(1). Excellent mechanical performance, high tensile strength, small elongation rate (less than 3%).

(2). Good thermal resistance

(3). Good dimension stability

(4). Good self-lubrication and wear resistance

(5). Good injection molding properties and appearance

(6). Good coloring performance

(7). Low temperature resistance

In 3D printing, the glass fiber increases the mechanical performance, wear resistance, thixotropy, dimensional stability, and thermal deformation resistance of nylon and effectively impresses the processability of nylon. Meanwhile, the glass fiber also increases the surface roughness of the products, impacting the appearance of products negatively. With the rapid development of 3D printing technology, the glass fiber reinforced nylon in 3D printing has also increased significantly. It not only enhances the mechanical performance to some extent but also improves the thermal shrinkage and poor dimensional stability of nylon, rendering a better 3D printing material.

| project | unit | Inspection methods | G10 | G20 | G30 | G30-1 | G45 |

| tensile strength | Mpa | ISO527-2 | 105 | 125 | 160 | 150 | 195 |

| elongation | % | ISO527-2 | – | – | – | – | – |

| bending strength | Mpa | ISO178 | 150 | 190 | 220 | 210 | 270 |

| bending modulus | Mpa | ISO178 | 4000 | 5500 | 8000 | 7000 | 10000 |

| KJ/m² | ISO179-1 | 8.5 | 11 | 13 | 20 | 18 |

| density | g/cm³ | ISO1183 | 1.2 | 1.28 | 1.37 | 1.36 | 1.53 |

| deformationtemperature | ℃ | ISO75 | 190 | 220 | 220 | 215 | 220 |

| Forming shrinkage | % | ISO294 | 0.4-0.8 | 0.2-0.6 | 0.2-0.6 | 0.2-0.6 | 0.2-0.5 |

| characteristic | universal type | universal type | universal type | Impact resistance | High rigidity |

ortheast university combined ground glass fiber with cast (MC) nylon to make MC nylon/glass fiber compounds. After adding 10% glass fiber, the shrinkage decreased but the thermal deformation temperature increased by 20 degrees. After obtaining the finished products, the tensile strength, bending strength, and compressive strength increased by 26%, 13%, and 36% respectively. Moreover, due to the high strength and good toughness, the maximum forming size of nylon glass fiber can be 300 mm X 300mmX 600 mm, and the maximum forming speed can reach 10mm/h. After receiving the 3D data, any complex models can be accomplished in a few hours without bonding. Compared to traditional cutting processing, the nylon glass fiber products in 3D printing can effectively shorten the model-making time and reduce the manufacturing cost.

Application fields of glass reinforced nylon: Electric tools: cutting machine, electric saw, electric drill, angle grinder, polishing machine, electric hammer, electric pick, hot air gun, lithium screwdriver, sanding machine, engraving machine, etc; Automotive Industry: cooling water chamber, intake manifold, mirror frame support, ventilation grille, door handle, throttle body, fan cover, shift control lever cover, handbrake, accelerator pedal, gear, etc; Machinery industry: water pump, water valve, bearing, shaft sleeve, gear, support, idler, etc; Sports equipment: ski equipment, baby carriages, bicycles, fitness equipment parts, etc; Office equipment: seat support, pulley, rotating shaft, shredder gear, printer parts, etc.

3.Processability of glass fiber reinforced nylon:

(1). Before processing, the glass fiber reinforced nylon should be fully dried. It can be circularly dried in hot air at 80-90 degrees until the water content is less than 0.3% to prevent moisture absorption after drying.

(2). High temperature is easy to oxidize and degrade. With meeting the molding process, avoid high solution temperature and long residence time in the barrel.

(3). Good flowability, easy to overflow, need to use the self-lock nozzles.

(4). Cooling speed of melt has an impact on the crystallinity, part’s structure, and performance, so the mold temperate should be controlled properly.

(5). For thin wall plastic part needs high transparency and flexibility, using low mold temperature. For thick wall parts with high stiffness requirements, good wear resistance, slight deformation, and high mold temperature are suggested.

(6). The thickness of the product should be even, and the demolding draft angle should be bigger, especially for thick walls and deep and high products, taking the larger value.

(7). When using screw injection molding machine is used, the screw with a high compression ratio is the right choice, and the screw head should be equipped with a check ring to avoid melt back flow.

(8). The temperature of the barrel varies according to the types of material, parts shapes, and injection types but is mainly decided by the melting point.

Nylon glass fiber is a cost-effective material with excellent properties, suiting for injection molding and 3D printing. You can select the material that you want for your parts. Get an instant quote by simply uploading your drawing. Contact GREFEE.

MORE BOLG

Insert mold in injection mold service

What are advantages and disadvantages of Zinc alloy and Aluminum alloy?

Inspection standards for injection molded partappearance

How to judge the quality of your plastic products?

Inspection standards for CNC machining

To ensure that your products are 100% qualified

Categories

Try GREFEE now,for free

We keep your uploaded files confidential and secure.