Analysis of factors affecting the accuracy of plastic injection

Molded parts and decrease in strength of plastic products

Posted on: April 11th,2024 By GREFEE

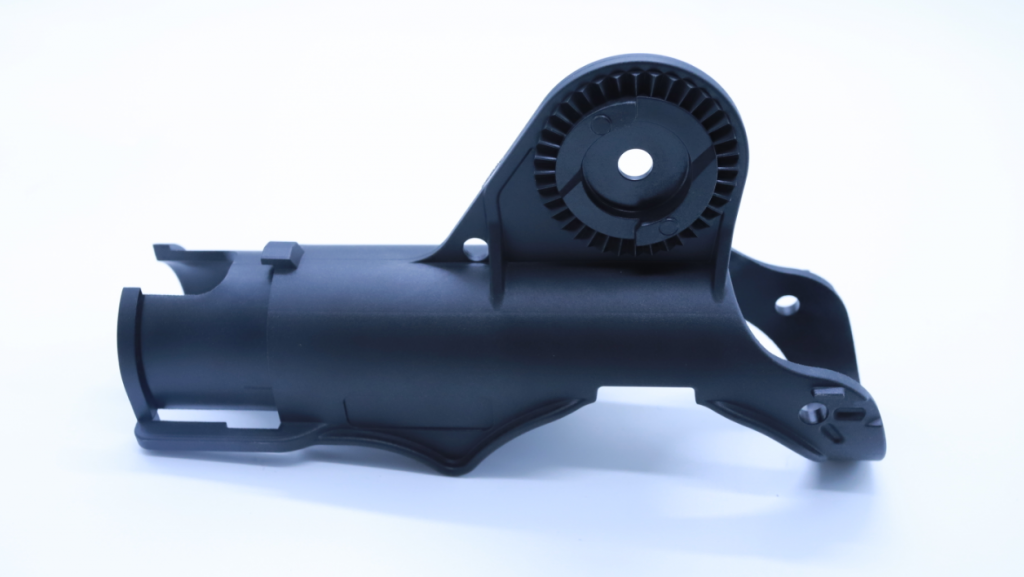

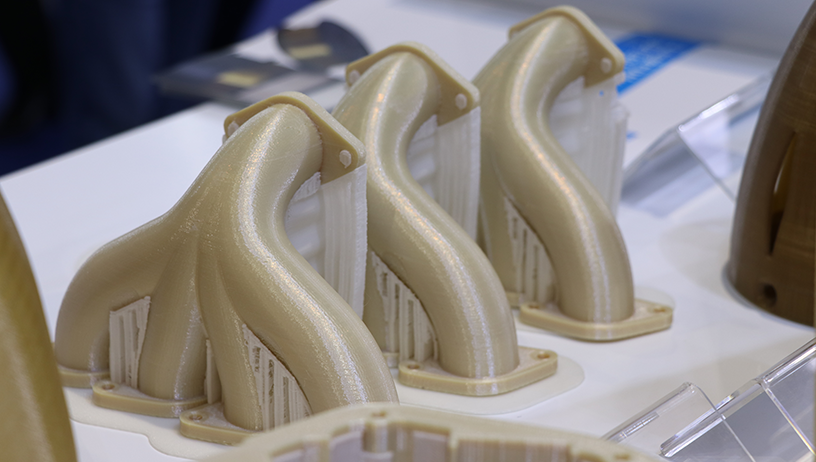

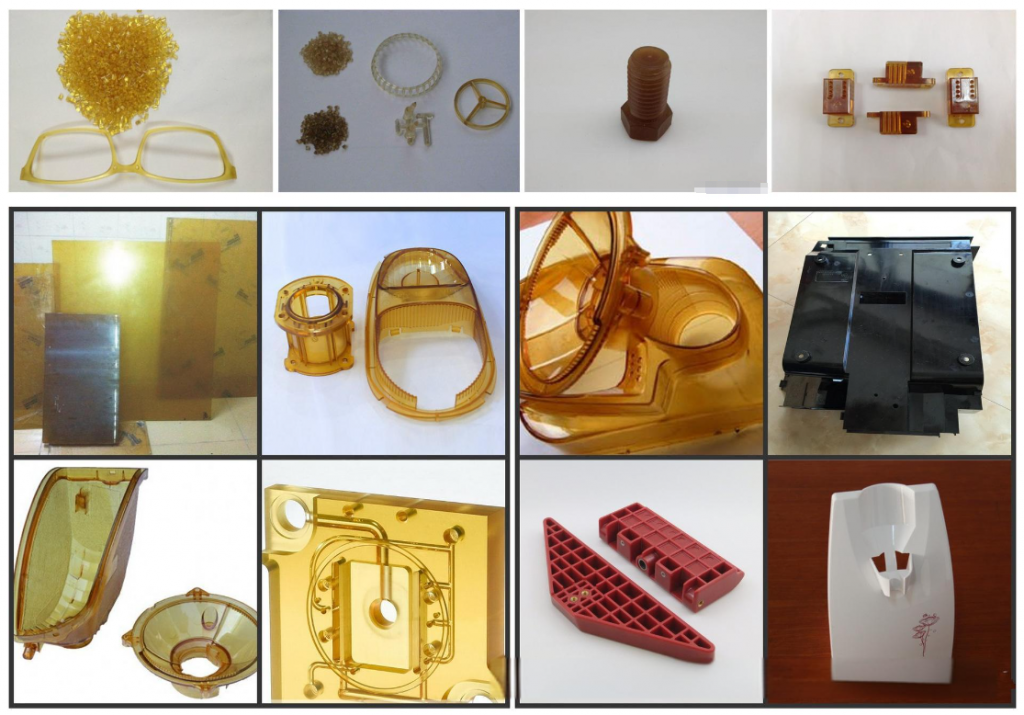

Plastic injection molding parts is widely applied in different modern industries. The accuracy and strength affect product quality and performance directly.

Thus, understand accuracy level and strength of plastic parts is essential for quality improvement and customer needs.

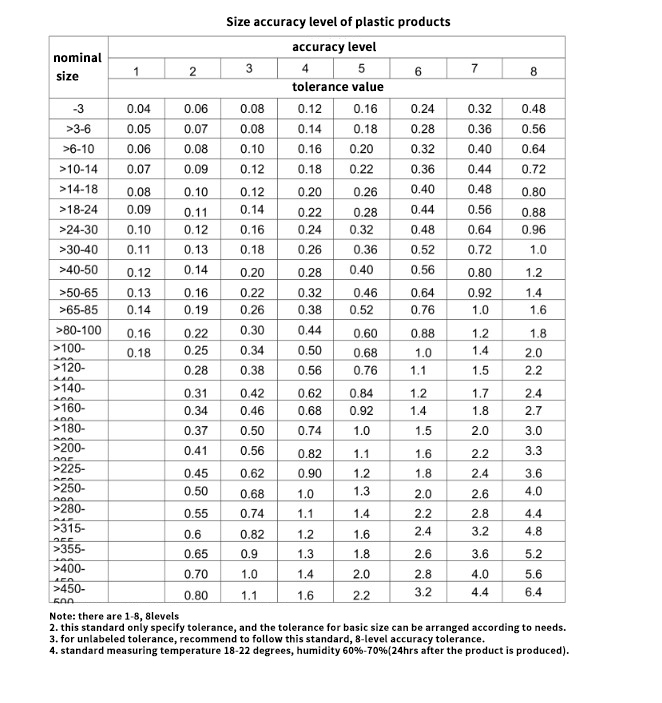

Firstly, we need to know the accuracy level of plastic parts.

It basically demonstrates the how much the dimensions of injection molded parts conform to the design dimensions of product drawings.

Generally, there are many accuracy levels, like level 8 accuracy level system.

the accuracy level of 1 and 2 are high, belongs to accuracy level, and need to be used under specific conditions.

In the application, the accuracy of parts can be affected by many factors, so low level accuracy is often utilized if it meets the needs.

Factors affecting plastic injection molding accuracy level:

1. molding material

The shrinkage, fluidity, moisture and volatile content, raw material configuration process, and production batch of plastics can directly or indirectly affect the accuracy of injection molded parts.

For example, the shrinkage varies from the kinds of plastic. The parts made of plastic with low shrinkage rate often have high accuracy than those of plastic with high shrinkage rate.

2. processing conditions

The molding temperature, pressure, time and shrinkage amount and setting of processing parameters will all affect the flowability and cooling rate, which further affects the accuracy of parts.

3. shape of parts, structure of injection mold, and accuracy

The shape, wall thickness, and molding shrinkage, and de-molding angle and other factors are also related to the accuracy level of a part.

4. accuracy, wear degree, and shape structure of molds

As the working environment is high temperature and high pressure, the plastic additives such as hard fillers, fiberglass, and carbon fiber will make the mold cavity size bigger due to the damages and friction.

Thus, the accuracy level of plastic injection parts are affected by the above factors, like molding material, processing conditions, shapes, injection mold, and the secular change after the product is finished,

During the production, we need to consider comprehensively through optimizing material selection, parameters adjustment, mold design modifying, and secular change of injection molding parts improvement to enhance the level of accuracy to meets the customer needs and achieve high quality requirement.

Meanwhile, during the injection molding process, the strength can be decreased as well.

It is common and caused by various factors, making it harder to find the cause for flaws.

It can be explained on three aspects: Injection molding equipment, injection molding process, and injection mold design

Common factors for lower strength:

Plastic decomposition – During the injection molding process, the decomposition may occur, leading to structural changes in its molecular chains and affecting the strength of plastic products

Low injection molding temperature – If the temperature is low, the incomplete melting of plastic may lead to a decrease in the strength of plastic products

Poor plastic fusion – If the plastic is not well fused in the molten state, the points at the joint will be weak, which can affect the strength of the product

Plastic is incomplete dry – if injection molding is carried out without drying treatment, it will cause bubbles, which will affect the strength of the product.

Mixing impurities into plastic – If the plastic is mixed with impurities, such as dust, metal particles, etc, it may disrupt the continuity of plastic molecular chains, therefore affecting the strength of the product.

Improper gate position – During injection molding, improper gate position may lead to uneven strength of the product

Inappropriate product design with sharp notches – Sharp notches can lead to stress concentration, thus reducing strength.

Insufficient plastic thickness of around metal inserts – Insufficient plastic thickness of the around metal inserts may cause insufficient strength.

low temperature of plastic injection molds – low temperature of injection molds will cause incomplete melting of plastic products, affecting their strength.

Multiple times of plastic recycling – the plastic properties of recycled materials may decrease as the recycled times increasing, and it could cause a decrease in the strength of the product.

So there are various reasons for the decrease in strength of plastic products.

During injection molding, the injection molding equipment, injection molding process, and injection mold design all impact the strength of plastic products. Therefore, we need to precisely control and manage them to improve the strength and quality of plastic products.

MORE BOLG

Insert mold in injection mold service

What are advantages and disadvantages of Zinc alloy and Aluminum alloy?

Inspection standards for injection molded partappearance

How to judge the quality of your plastic products?

Inspection standards for CNC machining

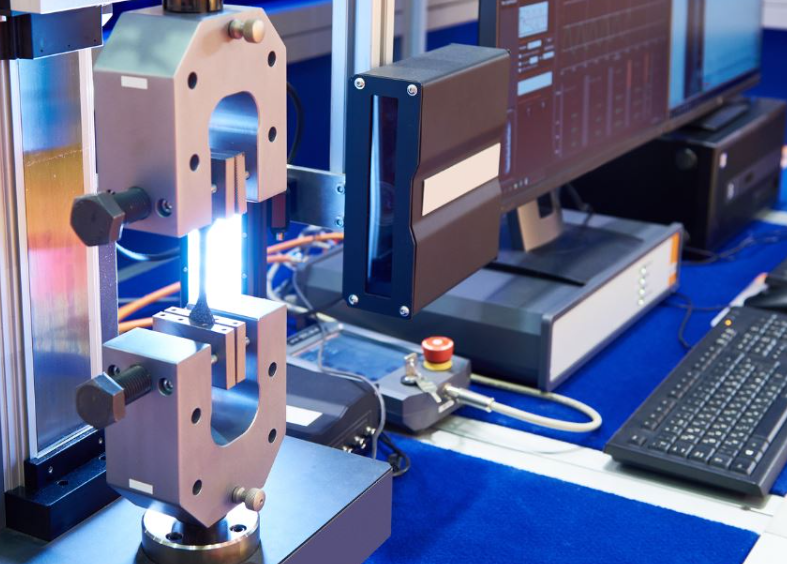

To ensure that your products are 100% qualified

Categories

Try GREFEE now,for free

We keep your uploaded files confidential and secure.