Classification of 3D printing technology

Posted on : June 5,2023 ,By GREFEE

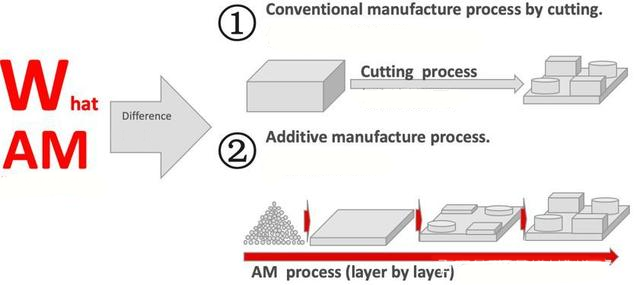

What is 3D printing, Taylor (2018) described the conceptual differences between subtractive manufacturing (traditional manufacturing) and additive manufacturing. Subtractive manufacturing is a manufacturing process that uses a solid material block larger than the final size of the product and then removes material until the desired product shape is achieved. Additive manufacturing is a manufacturing process that involves operating with very small amounts of material to continuously combine the material in the correct form directly from a CAD model to generate the desired part. It is a simple process that requires the operation of “two-dimensional” layers to manufacture the most complex parts, layer by layer, as shown in the figure below.

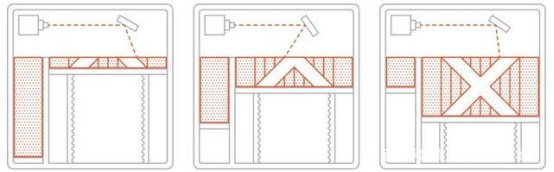

There are four types of metal 3D printing technology, including six technologies, as shown in the figure below.

1. Powder bed fusion technology

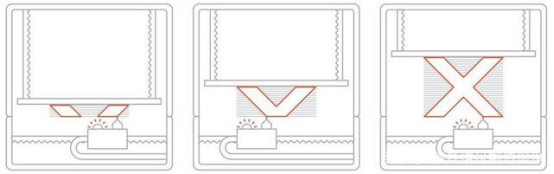

Powder bed fusion is a 3D printing process, producing solid objects by using a heat source to melt the metal powder particles together in one layer at one time. Most powder bed fusion technologies will add powder during the construction of the object, which encapsulates the final component within the metal powder. The main variations of metal powder bed fusion technology come from the use of different energy sources, with two major categories being laser or electron beam-based techniques.

Technical features:

Type of 3D printing: Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM), Electron Beam Melting (EBM).

Material: metal powder, aluminum, stainless steel, titanium

Size accuracy: ±0.1mm

Common applications: functional metal parts (aerospace and automotive), health and dental

Advantage: the most tough functional parts; complex geometry

Disadvantage: small volume, the most expensive technology for printing

Direct Metal Laser Sintering (DMLS)/Selective Laser Melting (SLM)

The Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) are both producing objects in a way that is similar to the SLS.

The main difference to distinguish these types of 3D printing is applicable to the production of metal parts. DMLS cannot melt the powder but to heat the powder to a certain degree so that the powder can fuse together at the molecular level. SML can melt the powder completely by laser to produce a even part, which results in single melting temperature of parts (the temperature that some alloys cannot produce). The main difference between DMSL and SLM is the former one is to produce parts by metal alloys, while the later one is to produce single element material, like titanium. Different form SLS, DMLS and SLM require structural support to limit the deformation even though the powder provides the physical support. DMLS/SLM parts will generate residual stress due to the high temperature during the printing process and thus it has a tendency of warpage. The parts also require heat treatment after printing and it still adheres on the bottom plate to reduce the residual stress of parts.

Electron beam melting (EBM), different from other powder bed melting technologies, EBM utilizes high energy beam or electrons trigger melting between metal powder particles. A focused electron beam scans a thin layer of powder, causing localized melting and solidification in specific cross-sectional areas to build up these regions and create a solid part. Compared to other 3D printing techniques such as SLM and DMLS, EBM typically has a higher build rate due to its higher energy density. However, features such as minimum feature size, powder particle size, layer thickness, and surface finish are typically larger. It is also important to note that EBM parts are manufactured in a vacuum and can only be used with conductive materials

Material spraying process

Material spraying is a process of 3D printing, among which the material drops will be selectively dropping on the curing panel and become cured. By using the photosensitive polymer or wax droplets cured under light, the objects can be piled into one layer at one time. The materiel spraying makes the different materials can be printed in the same object available. One of the applications of this technology is to produce prototypes with different kinds of materials to manufacture the support structure.

Types of 3D printing technology: Material Jetting (MJ), Drop-On-Demand (DOD)

Material: photosensitive resin (standard, cast, transparent, high temperature)

Common applications: full-color product prototypes; Injection molding pattern; Low speed injection mold; Medical model

Advantages: best surface finish; Available in full color and multiple materials

Disadvantages: brittle, not suitable for mechanical parts; Higher cost for visual purposes than SLA/DLP

Nano particle jetting (NPJ)

NPJ utilizes the liquid containing metal nano particles or carrier nanoparticles as the ink cartridge into the printing machine, then spray onto the construction tray with a very thin layer of droplets. The high temperature in the outer shell will lead to the liquid evaporation and leave metal parts.

Binder injection

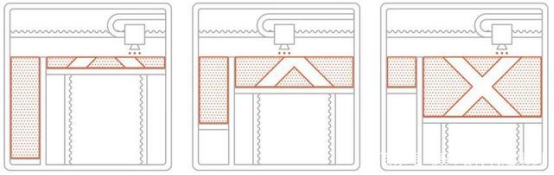

Binder jetting is a 3D printing process where liquid binding agent selectively bonds regions of a powder bed.

Similar to SLS, binder jetting requires an initial layer of powder on the build platform. However, instead of using a laser to fuse the powder, binder jetting moves a printhead over the powder surface, depositing droplets of binding agent typically with a diameter of 80 microns. These droplets bond the powder particles together to produce each layer of the object. After a layer is printed, the powder bed is lowered and a new layer of powder is spread on top of the newly printed layer. This process is repeated until the entire object is formed. The object is then left in the powder to cure and enhance strength. Afterwards, the object is removed from the powder bed and any unbound powder is removed using compressed air.

Technical features: <span style=“font-size:18px;line-height:107%;font-family:”&”>

Type of 3D printing technology: Binder Jetting (BJ)

Material: sand or metal powder: stainless steel/bronze, full-color sand, Silesia (sand casting)

Dimensional accuracy: ± 0.2 mm (metal) or ± 0.3 mm (sand)

Common applications: functional metal parts; Full color model; Sand casting

Advantages: low cost and large amount of construction; Functional metal parts

Disadvantages: mechanical properties are not as good as metal powder bed fusion

Metal bonder injection

Bonder injection is also applicable to the manufacturing of metal objects. The metal powder utilizes the polymer bonder to bond. Using bonder injection technology will produce metal objects in complex geometrical shapes, which exceeds the conventional manufacturing capability. However, the functional metal objects can only be produced by penetrating or sintering and other secondary process. The cost and quality of final result normally determines which secondary process is more suitable for the specific application. Without these extra steps, the parts produced by metal bonder injection will larger reduce the mechanical performance. The second process of infiltration works as follows: first, the metal powder particles are bonded together by the bonder and forms a green object. After the object is completely cursed, it will be removed from the loose powder and being put into a furnace to burn out the bonder. Now, the density of object is about 60% and the whole are is full of crevices. After that, bronze is used to achieve approximately 90% density and higher strength by infiltrating into the voids through capillary action. However, objects made with metal binder jetting typically have lower mechanical properties compared to metal parts made with powder bed fusion. A secondary sintering process can be used to manufacture non-porous metal parts. After printing is complete, the green-state objects are cured in an oven. They are then sintered in a furnace to approximately 97% of their high density. However, uneven shrinkage can be an issue during the sintering process and should be considered during the design phase.

Direct Energy Deposition (DED)

For DED, parts are manufactured by melting the powder material as it is deposited. It is mainly used for metal powder or wire, usually called metal deposition.

Technical field

LENS utilizes the deposition head, which is composed of laser head, powder distribution nozzle and inert gas pipe. When the powder is sprayed out through the nozzles, the powder can be melt to build solid part layer by layer. The laser creates a melt pool on a designated area of a substrate, and then metal powder is fed into the melt pool where it melts and solidifies. The substrate is typically a flat metal plate or an existing part that has been modified with additional material (e.g. for repairs).

EBAM is utilized to make part that is made of either metal powder or metal wire and utilizes electrical beam as the heating source to weld them together. Similar to the LENS, the electrical beam is more effective than the laser machine and can be operated under the vacuum condition. While, this technology is initially designed and used for the aerospace application.

Application field

The DED is specially used for the metal additive manufacturing, which means it is suitable for repairing or adding material into the exit parts, like turbine blade. Due to the dependence of DED on dense supporting structure, DED is not suitable for parts produced from scratch.

MORE BOLG

Insert mold in injection mold service

What are advantages and disadvantages of Zinc alloy and Aluminum alloy?

Inspection standards for injection molded partappearance

How to judge the quality of your plastic products?

Inspection standards for CNC machining

To ensure that your products are 100% qualified

Categories

Try GREFEE now,for free

We keep your uploaded files confidential and secure.