Gravity Casting

Professional quality can be trusted

Gravity casting refers to the process of injecting molten metal into the mold cavity under the influence of the earth’s gravity.

Gravity casting can produce thick-walled products, and there are no pores inside the product. The characteristic of gravity casting is that the mold cost is very cheap, and the mold can be finished making in 10-20 days.

Gravity casting process is widely used in automotive, Marine, aviation and aerospace, mechanical equipment, medical device and other industries.

Products producing by gravity casting have good mechanical properties after heat treatment, which is different from high-pressure die casting.

Grefee

Features of gravity casting

- Heat treatment can be done in case of the internal pores of the product are less.Then the intensity of product can be greatly improved after heat treatment even more than the die casting product.

- The product has low density and relies on liquid self-weight molding, but the elongation is high.

- The product surface finish is not high which similar to the effect of sandblasting.

- The mold warranty is longer than the die casting and the mold cost is low.

- slow filling, low production efficiency.

- It is not suitable for the production of thin-walled parts, and is suitable for the production of products with relatively thick walls.

Focus on aluminum alloy casting

According to customer requirements, samples, drawings for mold customization

sample, Drawing design

We can do mold customization according to customer requirements, samples, drawings.

Aluminum alloy casting

Professional design and production of all kinds of aluminum alloy casting mold, also aluminum alloy casting and machining integration.

High precision quality

Having professional equipment, we can test the size of aluminum alloy casting products in high-precision inspection; Strictly control product’s quality.

Wide range of applications

Aluminum alloy has low melting point, good casting performance which is widely used in automotive, medical, automation and other fields.

Application case

Products are widely used in automotive, medical, automation and other fields.

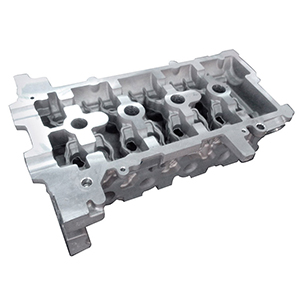

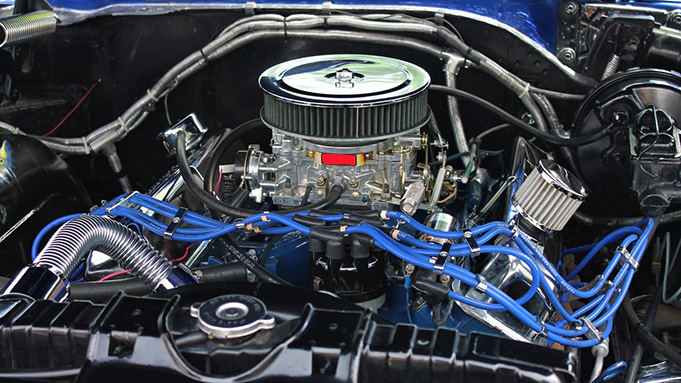

CAR INDUSTRY

There are about 20,000 parts that make up the car, and in these parts, a variety of materials are used. About 80% of them are metal materials, and metal materials have an irreplaceable position in the automotive industry.

HEALTH CARE INDUSTRY

As a new type of alloy, medical titanium alloy is also a carrier material, which is widely used in limb implants, alternative functional materials, dentistry, medical devices and other related fields.

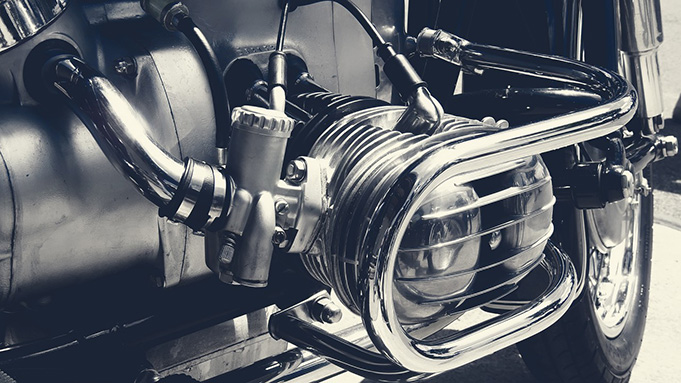

MOTORCYCLE

Aluminum alloy is mainly used in motorcycle engine box, cylinder block, cylinder head, cylinder head cover, wheel spoke and other parts, accounting for about 80% of the entire motorcycle aluminum.

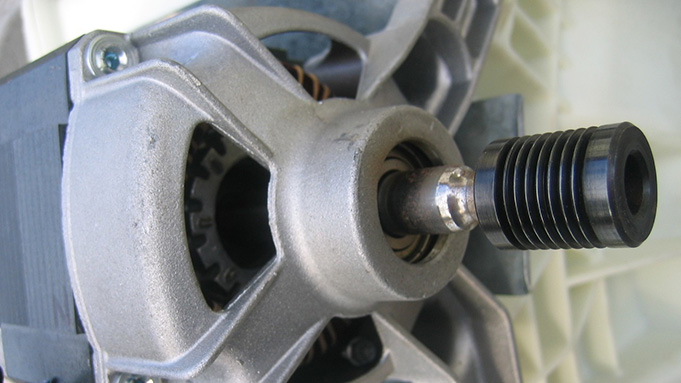

MOTOR

The aluminum alloy in the motor has the characteristics of low density, corrosion resistance, high specific strength and stiffness, good plasticity, easy processing, easy welding, simple process, beautiful and durable, easy to reuse, low cost and so on.

HARDWARE TOOLS

At present, many stainless steel hardware is used, but the stainless steel material has shortcomings such as impure material and easy to print water stains, and many families have begun to use aluminum alloy accessories.

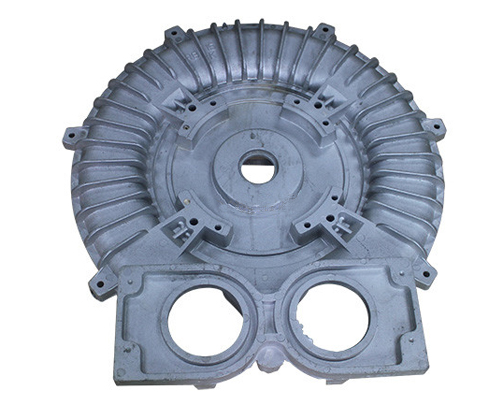

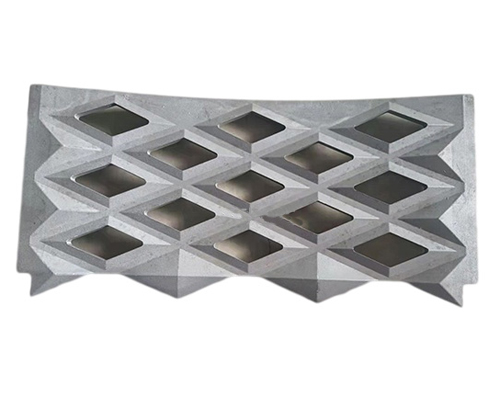

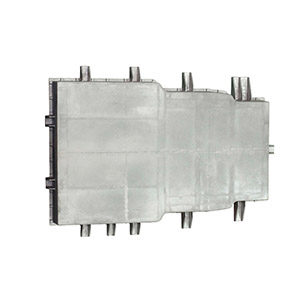

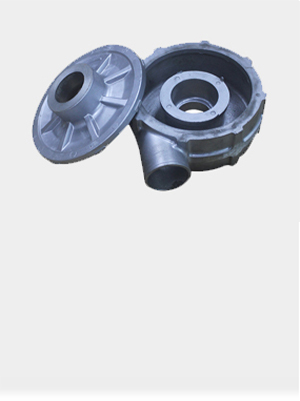

Gravity Casting Product Display

The surface of the product has no bad phenomena such as loose, slag inclusion, sand hole, etc

PRODUCT

CATEGORY

Pump body seal series

Large machinery series

New energy motor series

Robot body series

Machine tool accessories Series

Curtain wall accessories Series