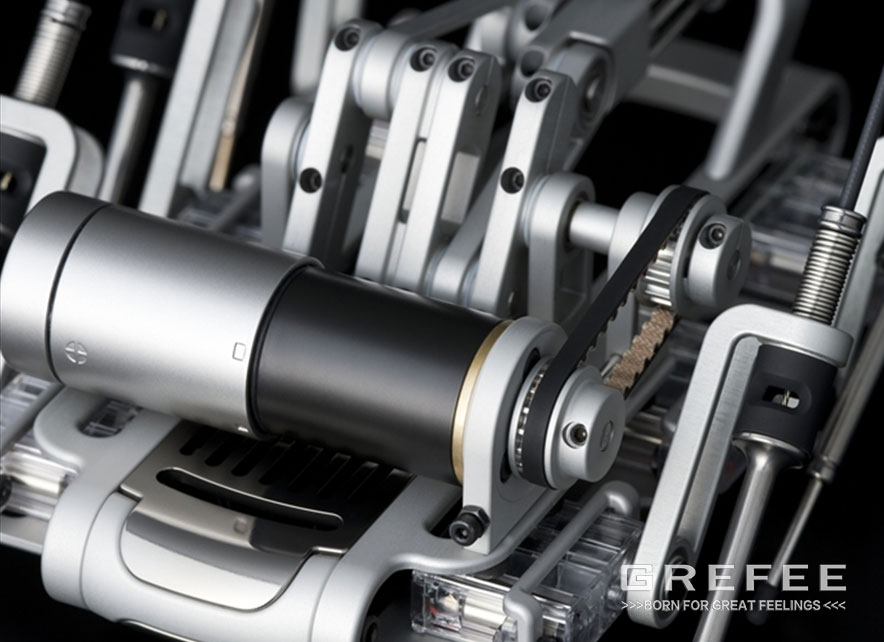

Innovative design of mechanical structures

Posted on : Mar 25 , 2023 , By GREFEE

Mechanical structure design refers to the design of the structural shape of components and the connection relationships between components. It is the main component of mechanical design, and is the work stage with the most problems, the most specific details, and the largest workload. In these specific processes, it is necessary to consider the influence of various factors such as the mechanical properties of materials, component functions, working conditions, processing technology, assembly, use, cost, safety, and environmental protection. Structural design is not a simple repetitive operational work, but a creative work. Rich knowledge is the prerequisite for engaging in structural design work, and clever combination of shapes is the core of creative structural design.

The structural design of a mechanical system involves the design of the shapes, sizes, positions, quantities, materials, heat treatment methods, and surface conditions of all components. In addition to meeting the motion requirements specified in the principle scheme, the structure should also satisfy the design requirements for strength, stiffness, precision, stability, manufacturability, service life, reliability, and other aspects. One of the important features of mechanical structural design is the existence of multiple solutions to design problems, meaning that there is not a unique mechanical structure that satisfies the same design requirements. The task of mechanical structural design is to seek a better or optimal solution from among the many feasible structural design schemes. The variation design method of structural schemes allows the designer to generate a large number of feasible solutions by starting from a known feasible structural design scheme and transforming it. Through optimization of the parameters in these schemes, the designer can obtain multiple local optimal solutions, and by analyzing and comparing these local optimal solutions, the optimal or global optimal solution can be obtained. Creativity and innovative thinking are required to achieve this.

Variation Design of Structural Scheme

The purpose of variant design of a structural scheme is to seek independent design schemes that meet the design requirements, so that parameter optimization design can be carried out. The basic method of variant design is to first analyze the technical elements contained in the general structural design scheme through structural design scheme analysis. Then, by analyzing the range of each technical element, a sufficient combination of independent structural design schemes can be obtained by considering the full combination of technical elements within their respective ranges. Generally, the technical elements of mechanical structures include the geometric shape of parts, the connection between parts, and the material and heat treatment methods of parts. The following analyzes the variant design methods for these technical elements.

1 variation design of functional surfaces

The main function of mechanical structure relies on the geometrical shapes of mechanical parts and the relative places of each part to achieve. The geometrical shapes is composed of its surface. One part usually have multiple surfaces. Among these, the surface that contacts with other surfaces of parts and the working mediums or workpieces is called the functional surface.

One of the important factors determining the mechanical functions is the functional surface of parts. The design of the functional surface is the key of the part design. Through variation design on functional surfaces, multiple structural solutions can be obtained to achieve the same technical function. The main geometric parameters of functional surfaces include the shape, size, number, position, and sequence of the surface. By varying these aspects, multiple sets of configuration solutions can be obtained.

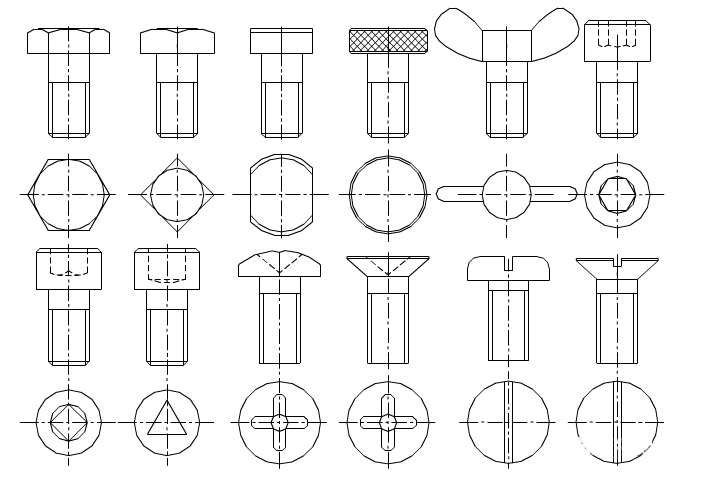

1.1variation design of the working surface of a screw head:

1.2 Variation of Connections

A part that is not contacted with other parts has six free degrees. In mechanical design, certain degrees of freedom of parts are limited by specifying the appropriate connection mode between parts, and the necessary degrees of freedom for the function of the machine are reserved, so that the machine can realize the definite form of motion relationship in the work.

Connection works by the contact between the surfaces of different parts. The tighten force between surfaces and the restriction to the free degrees vary due to the difference of contacted working surface and connections.

Like the hub connection, the restrictions of the connection between the shaft and the hub on the relative freedom of motion may include:

1) Fixed connection: limit 6 relative motion degrees of freedom

2) Sliding joint: limit 5 relative motion degrees of freedom.

3) Rotary connection: limit 5 relative motion degrees of freedom.

4) Moving and rotating connection: limit 5 relative motion degrees of freedom.

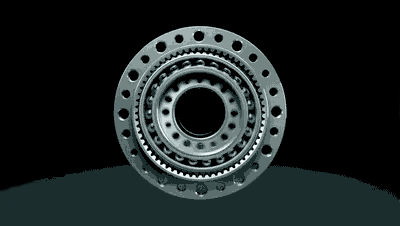

According to the conditions for forming the locking force in the connection, the fixed hub connection can be divided into shape locking connection and force locking connection.

Force-locking joints rely on the frictional force generated between the surfaces of the joined parts to transmit torque and axial force. The generation of surface pressure can be achieved through various structural measures. Interference fit is a commonly used structural measure that achieves sufficient pressure with the simplest structure shape. However, it has the disadvantage of being inconvenient for assembly and disassembly and causing significant stress concentration. Common forms of locking joints include pin joints, flat key joints, half-round key joints, spline joints, formed joints, and tangential key joints. To construct a force-locking joint structure that is easy to assemble and disassemble, there must be no interference between the surfaces during assembly. After assembly, other adjustment measures are used to create interference between the surfaces, and the opposite is true during disassembly. Common force-locking joints include wedge key joints, elastic ring joints, cylindrical interference fit joints, conical interference fit joints, threaded joint, tolerance ring joint, star disk joint, press fit joint, and hydraulic expansion joint. The working performance of force-locking joint shaft systems is closely related to the condition and quality of their support design.

1.3 variation of material

In mechanical design, there are many types of materials to choose from, each with different properties, and different materials correspond to different processing techniques. In structural design, it is necessary to select appropriate materials based on functional requirements, determine appropriate processing techniques based on material types, and determine appropriate structures based on processing technique requirements. Only through appropriate structural design can the selected materials be fully utilized. To correctly select structural materials, it is necessary to fully understand the mechanical properties, processing properties, and usage costs of the selected materials.

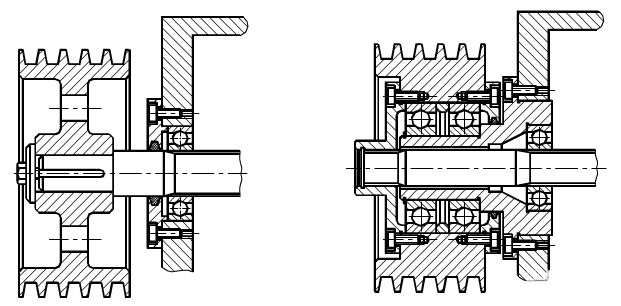

Just like the design of elastic coupling requires the materials of elastic elements include metal, rubber, nylon, bakelite, etc. Due to the different elastic elements, the structural change of elastic coupling varies significantly. Due to the short service life of elastic coupling, so it needs to be changed multiple times. In structural design, it is important to provide the possibility and convenience for replacing elastic elements, and to leave necessary operating space for replacing them so that the number of parts that need to be disassembled or moved for replacing elastic elements is minimized.

The designing principles of structural design should be based on the characteristics and the corresponding processing methods.

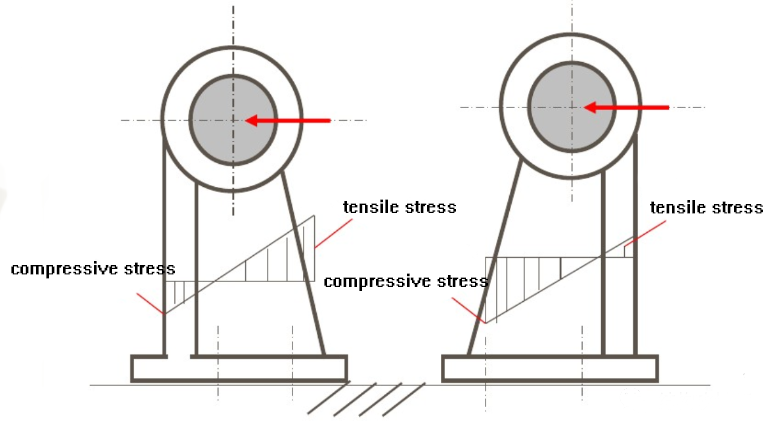

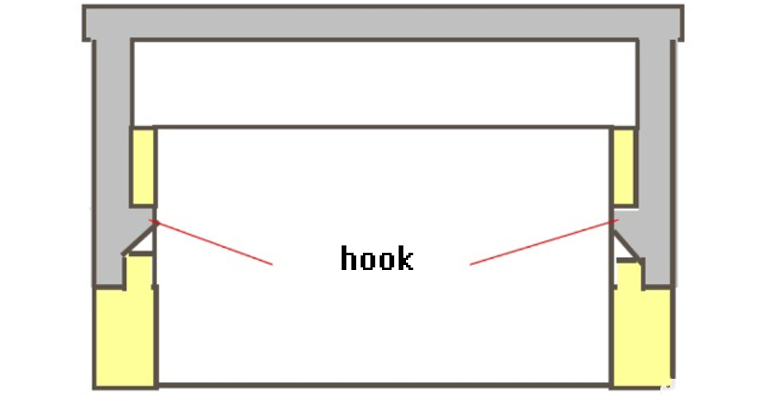

The mechanical properties of steel under tension and compression are basically the same, so steel beam structures are mostly symmetrical. The compressive strength of cast iron material is much greater than its tensile strength, so the cross-sections of cast iron structures that bear bending moments are mostly asymmetrical in order to ensure that the maximum compressive stress is greater than the maximum tensile stress during loading. Plastic structures have poor strength, and the assembly forces generated by threaded connectors can easily damage plastic parts. To address this, simple hooks and grooves are made on two connected parts, and during assembly, the elastic deformation of the plastic parts is utilized to interlock the hooks and grooves, achieving a simple and accurate assembly process that is easy to operate. The results of the design must be realized through manufacturing and assembly, and if the structural form can be reasonably determined based on the process characteristics of the selected material in the design phase, it will bring convenience to the manufacturing process.

When designing the structure, it is also necessary to consider the influence of working conditions and external factors on the performance of the parts. For example, in high-speed belt transmission, transverse grooves are generally opened on the non-working surface of the belt to increase its flexibility. The pulley is usually made drum-shaped and keeps the belt in the middle during operation to prevent detachment. To avoid the generation of air cushions between the belt and the pulley, which affects the reliability of power transmission, an annular groove is opened on the rim of the small pulley.

Make best use of the advantages and complement each other in performance.

The structural shape should facilitate the performance of the material. For example, cast iron has a higher compressive strength than tensile strength, so it should be designed to withstand compressive stress to fully utilize its advantages. Ceramic materials have poor ability to withstand local concentrated loads, so their weaknesses should be avoided in connections with metal components. Plastic is one of the commonly used processing materials. It is lightweight, low-cost, and can be made into complex shapes, but has low strength and stiffness, and is susceptible to aging. Reasonably combining rigid and flexible materials, imparting flexibility to some parts in rigid components, can compensate for geometric errors in working surfaces using contact deformation.

2. Structural innovative design method to improve performance

The performance of mechanical products is not only related to the designing principles but also the quality of structural design. This factor also impact the achievement of product function. The design methods and principles commonly used to improve the strength, stiffness, accuracy, and processability of the structure are analyzed below. Strength and stiffness are the basic issues of structural design. Through correct structural design, the material stress and deformation caused by unit load can be reduced, and the bearing capacity of the structure can be improved.

2.1 Both strength and stiffness are related to the structural stress. With the constant external load, the effective measure to improve the strength and stiffness is to reduce the structural stress.

(1). Structural stress caused by load sharing

If multiple loads act on the same structure, it may cause local stress concentration. In structural design, loads should be distributed among multiple structures to reduce stress concentration in critical areas and improve the overall load-bearing capacity. This method is called load sharing.

When bending moment and torque act on the same structure, it may cause excessive stress on the shaft. To reduce stress on dangerous sections of the structure and increase its load-carrying capacity, the load should be distributed among multiple structures. This method is called load sharing. In the structure, a support sleeve with a pulley is added to transfer the torque to the shaft through an end cover, and the axial force is transmitted to the support sleeve through the bearing.

(2). counterweight balance

In mechanical transmission, some forces that do work must be transmitted along the transmission chain, and some forces that do not do work should be shortened as far as possible. If it forms a balance force system with other loads of the same kind in the same part, other parts will not be affected by these loads to improve the bearing capacity of the structure.

(3). stress concentration reduction

Stress concentration impacts the bearing capacity of the structure significantly under alternating stress. Structural design should try to alleviate stress concentration as the force flow will change when the section shape of the part changes, and the increase of local force flow density will cause stress concentration. The more sudden the change of the section shape of the part, the more serious the stress concentration will be. In the structural design, try to avoid the sudden change of the shape of the part at the place where the stress is relatively large, so as to reduce the impact of the stress concentration on the strength. When the part is deformed under force, the different deformation resistance (stiffness) at different positions will also cause stress concentration. In the design, the stress concentration can be effectively reduced by reducing the local stiffness near the stress concentration. Due to the need of structural positioning and other functions, structural size and shape changes will inevitably occur in most structures. These changes will cause stress concentration. If multiple changes occur at the same structural section, it will cause serious stress concentration, so it should be avoided in structural design.

2 .2 Design to improve mechanical accuracy

Through structural design, the original errors caused by the manufacturing and installment can be reduced, errors caused by the temperature wear and part deformation, and also reduce the sensitivity of actuator to various errors. The errors occurred during the manufacturing and installment are inevitable, but the actuator errors can be reduced by appropriate structural design without changing the original errors. The test result shows that the error of screw drive can be less than the pitch error of screw itself. The cumulative measurement error of the micrometer.

(1)Error homogenization principle of mechanical accuracy

In the mechanism, if there are multiple connection points which simultaneously restrict a kind of motion, the motion error of the moving part is determined by the comprehensive influence of each connection point, and its motion accuracy is higher than that of one connection point. Under certain conditions, increase the number of thread turns that work in the screw drive to make multiple threads work at the same time. It can not only improve the bearing capacity and wear resistance of the screw drive, but also improve the transmission accuracy

2.3 Improving processability

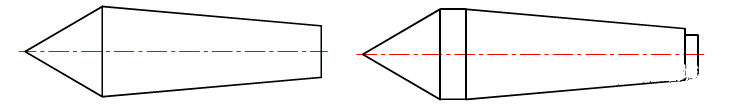

The structural design is related to the the equipment characteristics of mechanical cutting lathe for providing the required clamping surface to install the part. The shape and position of clamping surface should enable the parts with sufficient rigidity under the cutting force. The machined surfaces on the part should be completed with as few clamping operations as possible. If multiple related surfaces on the part can be machined through a single clamping operation, it will effectively improve the machining efficiency.

For example, in the above figure, there are only two tapered surfaces used, and the chuck cannot be clamped. Two cylindrical surfaces are added, which do not play a role in the work of the part, but are set up to achieve the process. These surfaces are called process surfaces.

The more geometric surfaces to be formed for cutting, the greater the amount of work required for processing. In structural design, it is an important principle to minimize the number and types of processing surfaces.

Simplifying assembly, adjustment, and disassembly: processed components need to be assembled to become a complete machine. The quality of assembly directly affects the operating quality of the equipment. Whether the design considers the needs of the assembly process also directly affects the difficulty of the assembly work.

3. User-friendly design

User-friendly design refers to the structural shape of mechanical equipment that should meet the physiological and psychological requirements of people, making the operation safe, accurate, effortless, simple, reducing operational fatigue, and improving work efficiency.

3.1 Structure for reducing operator fatigue

During the structural design and configuration, the operator’s force situation should be considered to avoid the operator maintaining a non-natural posture for a long time. The following figure shows the structural shape of various manual tools before and after improvement. The original structural shape was rigid, and the operator was in a non-natural state for a long time during use, which was easy to cause fatigue. After the improvement, the structural shape became soft, and the operator was basically in a natural state during use, and did not feel fatigued even after long-term use.

3.2. Structures that improve operational capability

When operating machinery or equipment, operators need to exert force, and the force exertion ability differs significantly depending on the posture, direction, and means of force application. Generally, a person’s grip strength is greater in the right hand than in the left. The strength of the feet also depends on the posture. When sitting, the pushing force of the feet is greater, and when the operating force exceeds 50-150, foot force control is preferred. The shape of handwheels, handles, or levers for manual operation should be designed to be comfortable to grip and not slippery, and for foot operation, sitting posture is preferable, with a backrest and foot pedal positioned centrally in front of the seat.

3.3 reduce operational errors

To reduce operational errors, the shape of the operating parts should be simple and easy to recognize. The operating position should be appropriate and within reach of the operator’s hands or feet. A seat that can reduce fatigue should be provided to the operator, and the indicator should be within the operator’s field of vision.

3.4 shape and color

The shape of part should be matchable with the functions of parts, material of parts, load characteristics, and processing methods. In the meantime, it also should be fit with the human reaction. In addition to meet up the function, processing conditions, material characteristics, but the harmonious, balanced, and stable external shape.

4. Structural Design and Innovation for Convenient Manufacturing and Operation.

Designers should strive to make the structure of their products simple, cost-effective, easy to use and operate, and with a long lifespan while still meeting functional requirements. The design should minimize material consumption and reduce manufacturing complexity.

4.1 Structural configuration of processing technology

For machined parts, the configuration should consider factors such as shorter clamping, machining and measurement times, and lower equipment costs. This is mainly reflected in the shape of the machining surface, which should be as simple as possible, with dimensions as small as possible, and positions that are convenient for clamping and tool exit. It is also important to avoid drilling on inclined surfaces and complex machining on inner surfaces.

For complex parts, increasing the number of machining processes will result in material waste and increased costs. To address this issue, combination parts can be used to achieve the same function. Although the machining difficulty may be greater, if the small shaft is replaced with an assembled component, processability can be improved without losing its original function.

4.2 simple structure

Only refined and simple things are the progress of design, and also the desire of designers.

Simplification of joint structures. For example, the strength of plastic structures is relatively poor, and using threaded connections to join plastic parts can easily cause damage and result in complicated manufacturing and assembly processes. By fully utilizing the large elastic deformation of plastic parts, connecting them with simple hooks and grooves can simplify the assembly process, make it more accurate, and easier to operate.

Simplification of hinge structures. Hinge structures made of metal are relatively complex. For hinge connections with small loads, they can be greatly simplified by using plastic materials.

5. Conclusion

Mechanical innovated structure design is essential to the industrial development, and thus it is valuable. However, it is not easy to achieve, which has rigorous and high requirements to the designers and researchers, not only to be proficient in the professional knowledge but also the analytical ability, problem solving skills, innovation thinking and knowledge. The innovation of structure is not just a fantasy, but a new requirement based on the current technology improvement or to innovate to meet up the new requirements in our daily life.

Two aspects to achieving successful innovative design: first, acquiring applicable knowledge; second, using a design system that is in line with innovative thinking and capable of inspiring creative ideas. The design process is full of contradictions, and the knowledge obtained should help quickly resolve these contradictions. Additionally, human innovative design thinking is formed by summarizing long-term successful design experience. Starting from the research of innovative design thinking and integrating knowledge acquisition methods, innovative design theories such as TRIZ can be studied.

MORE BOLG

Insert mold in injection mold service

What are advantages and disadvantages of Zinc alloy and Aluminum alloy?

Inspection standards for injection molded partappearance

How to judge the quality of your plastic products?

Inspection standards for CNC machining

To ensure that your products are 100% qualified

Categories

Try GREFEE now,for free

We keep your uploaded files confidential and secure.