Magnesiums die casting alloys

GREFEE is proficient in magnesium die casting alloys manufacturing like automtive lightening brackets, automotive rails, 5g telecommunication etc.

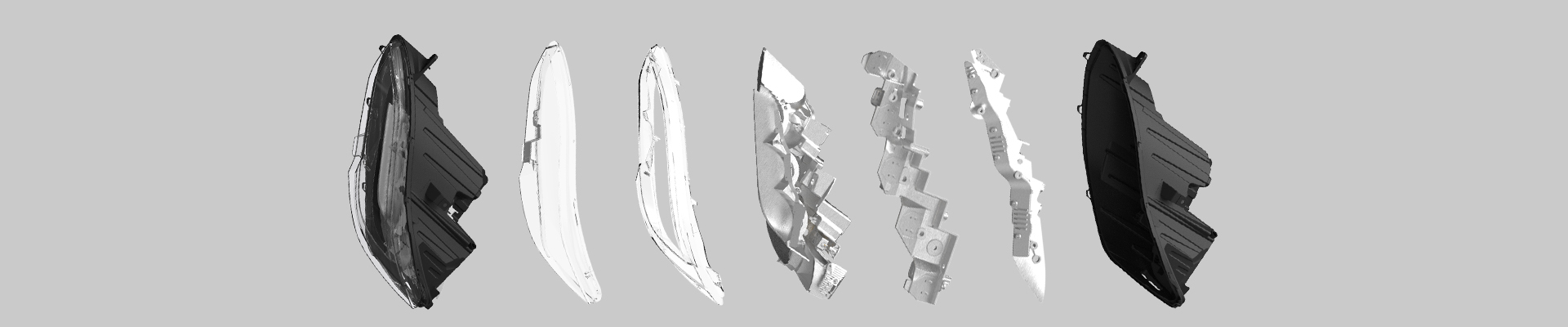

Automotive Lightening supports

Model: Tesla

Material: AZ91D(Magnesium alloys)

Process: Die casting – Trimming – CNC machining – Ultrasonic cleaning – Quality inspection- Packaging

- GREFEE engineers assist customers with designing process

- GREFEE manufactures RH&LH components of headlights and taillights dies

- Heat dissipation rates of AZ91D magnesium alloys is 75% higher than aluminum alloys

- Magnesium alloys can save 1.2KG mass per vehicle

- 2600 units qualified production daily

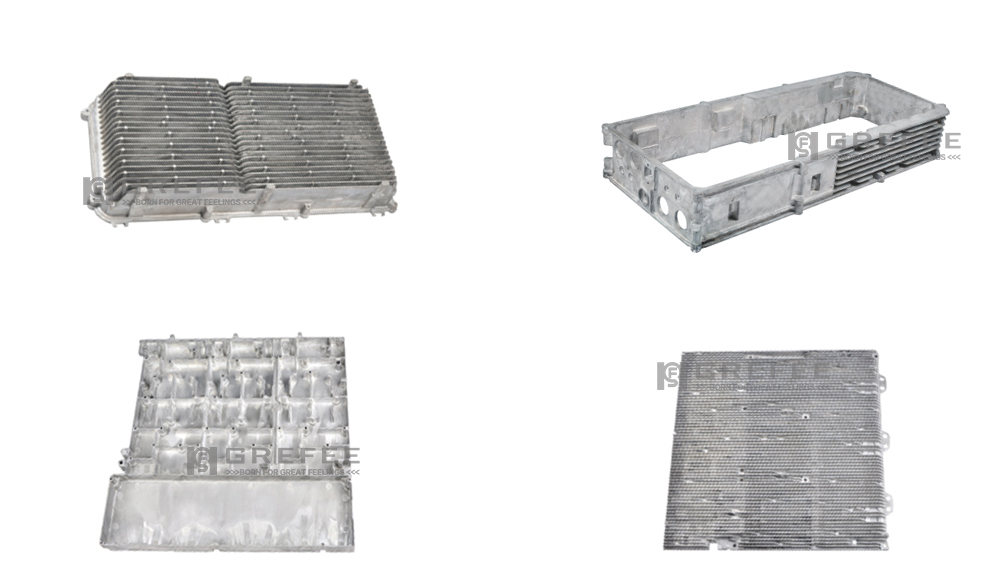

Radiators for automotive lightening

Model: Volkswagen

Material: AZ91D(Magnesium alloys)

Process: Die casting – Trimming -CNC machining – – Ultrasonic cleaning – Quality inspection- Packaging

For product design, even just 1g saved matters and it can extends the battery life of vehicles. Magnesium is becoming a cutting edge of electrical cars manufacturers. GREFEE plays a critical role in this market. There are more than 20 headlights components for two cars. With the innovated machining technology and 5-axis machining, we are confident that we can provide the most cost-effective solutions for customers with superior quality and battery life.

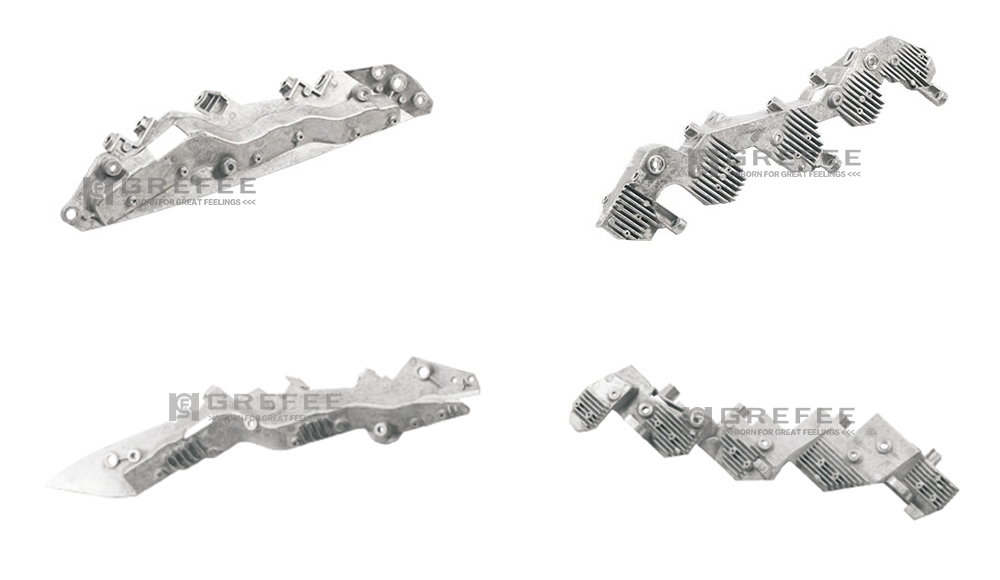

Audi A4L Armrest-Magnesium bracket

Model: Audi A4L

Material: AM50A

Process: Molding – Trimming – Tumbling – CNC Machining – Ultrasonic Washing

- AM50A alloy for high impact resistance and vehicle safety

- 1 kg of mass saved per vehicle

- Tooling constructed in house by GREFEE

- CNC Machining at GREFEE

- Periodic X-ray inspection to ensure lot integrity

- No coatings or special treatments of the magnesium

Automobile Armerest – Magnesium Bracket

Material: AM50B

Process: Molding – Trimming – Tumbling – CNC machining – Ultrasonic

washing

- AM50B Alloy for high impact resistance and vehicle safety

- 1 kg of mass saved per vehicle

- Tooling Constructed In-House by GREFEE

- CNC Machining at GREFEE

- Periodic X-Ray inspection to ensure lot integrity

- No coatings or special treatments of the Magnesium

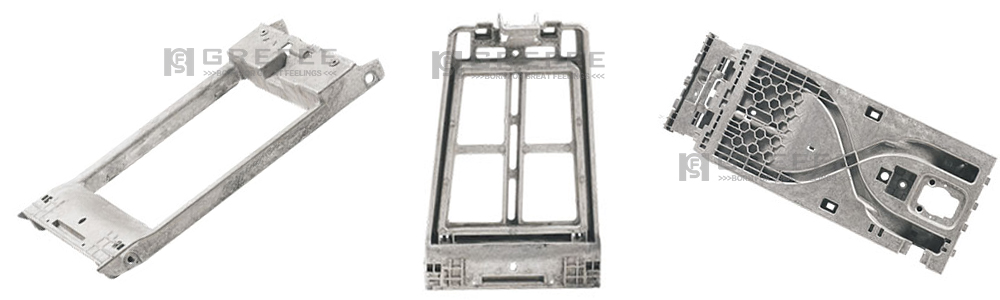

Magnesium in Telecommunication

The high fluidity of molten magnesium and the excellent heat sinking properties of the material make it a great heat sink material for high power electronics. But our customers love magnesium for other reasons such as : better electromagnetic and radio frequency interference (EMI and RFI) control than those of aluminum. Ever wondered how your cellular signal stays so clear with the help of Magnesium.

- Fins and tooling design with maximum optimization by GREFEE engineers

- AZ91D alloy achieves temperature control within 5% of aluminum

- 30% weight reduction and BETTER signal clarity than aluminum

- Constructed all the tooling at GREFEE

- Superior tool life and surface finish quality than aluminum