Methods to lower the cost for zinc alloy die casing parts

Posted on : May 4, 2022 By GREFEE

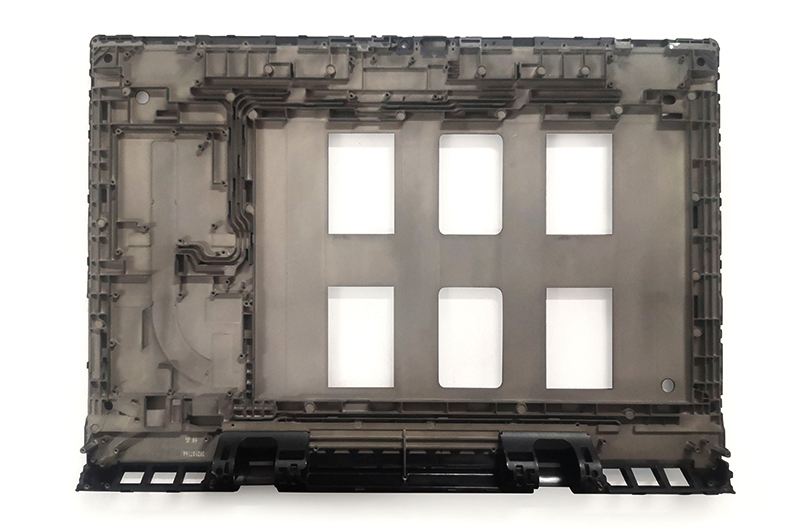

Zinc alloy castings are used widely in automotive parts, the mechanical industry, and the automation industry. Generally, as zinc alloy castings come into a large size and are settled with weight units rather than quantity units when the price of zinc alloy goes up, enterprises must pay a high purchasing cost. Besides, due to the large machining allowance, the machining cost increases artificially, too. Moreover, this will seriously affect the accuracy of machining equipment, which increases the difficulties for the die casting factories to lower the cost and increase their competitiveness in the market. Therefore, the cost of zinc alloy castings is related to several factors, including quota accounting, structural design, quota management, and procurement. Not only these, but it also needs to adapt the scientific management system and methods.

Quota calculation and summary

Two things need to be paid attention to for better performing the quota accounting and summary.

1.appropriate standards

Zinc alloy castings can be divided into several types according to the variations in their materials and casting methods: gray cast iron, nodular cast iron, cast steel, ordinary casting, precision casting, etc. The standards of zinc alloy castings varied in their internal structure and compositions. The more important things are the difference in the machining allowance, surface roughness, and other requirements. Indeed, Higher requirements lead to a higher price. Therefore, the appropriate standards are fundamental to the price. Which standard should select depends on the user requirements and all comprehensive use situations. The general standard is to follow the one with low demands and is suitable to cast without affecting the appearance and use effect. Try to select casting with a small machining allowance. With these, the castings produced are economical, well-designed, and practical.

2.Accurately calculating weight quota

There are two methods to get the weight quota:

Generally, we use the calculation method of 3D design;The other is the method of weighing.

It should notice that no matter which method, we should design a two-dimensional structural pic first according to the appropriate allowance and machining requirements, working as the reference for the casting supplier and three-dimensional design. The purpose of doing it is to avoid the leakage of confidential information. The casting drawings do not contain information like the dimensional tolerance of parts or tolerance of the form and position. Thus, it ensures the security of confidential technology. Meanwhile, a two-dimensional casting drawing can be the reference for designing the three-dimensional and inspection basis during weighing.

The three-dimensional method is by creating a three-dimensional model according to the dimension of the castings and then obtaining the value of the component volume by the calculation tools of the three-dimensional design software. The volume plus the density of the material is the weight. Weighing the parts are finally checked by different departments of Technology, inspection, Discipline Inspection Commission, Finance, and Production. The first is to inspect the dimension and weight and record these values to see if the size of the castings meets the requirements of the design drawing. Next is to let the staff involved in the design sign the report. After finishing the weighing, we need to do the classification, statistics, and summary.

3.The machinability and reasonability of casting design.

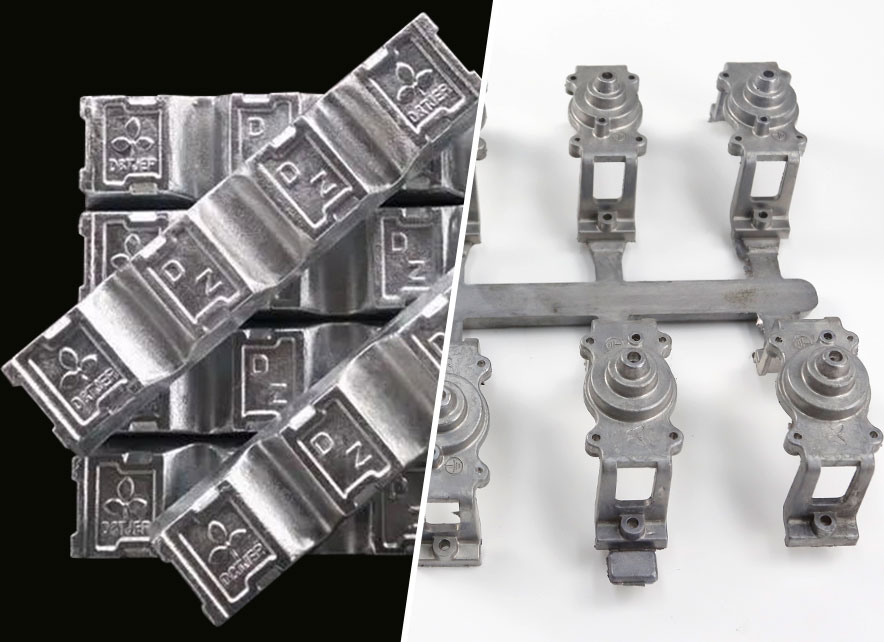

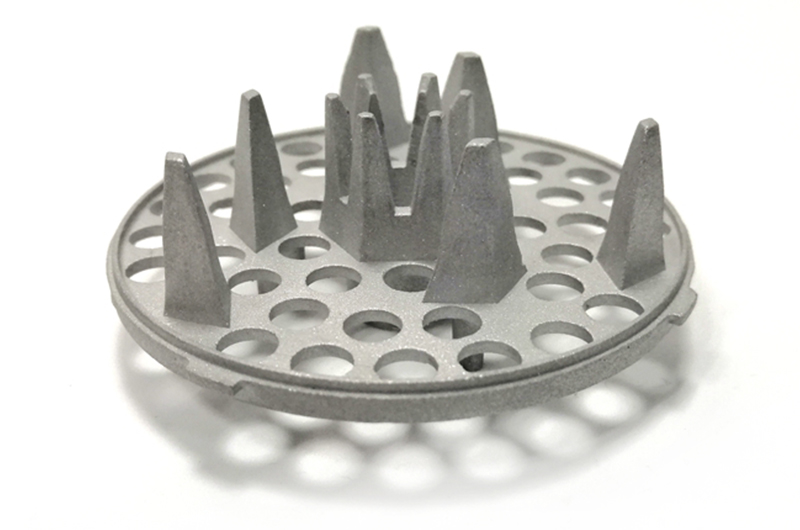

The machinability and reasonability of the casing design directly affect the machining difficulty, quality effect, weight, and cost. Therefore, the machinability and reasonability of the structure is another effective method for lowering the cost of castings. Take the attached pic as an example. It asks to process both sides with a machining size of 42mm. The machining length of the original structure is 170 mm. After the structural modification, in the attached pic b, a structure of boss added not only reduces the weight of the parts but also decreases the machining surface without affecting the using effects. It lowers the procurement and machining costs. This is only one among many successful application cases. However, it illustrates the structural machinability and reasonability in two-dimensional design.

GREFEE is certified with ISO 9001, 13485, 16949 and other certifications. We are good at manufacturing automotive castings and medical parts. Start your new project with us!

4.Establish standardized rules for the casting procurement and quota management.

To establish an organized and transparent procurement process, quota management, and settlement system, a specific management and monitoring system is necessary. To avoid the flaws and produce castings at a low cost, we need to perform the quota calculation and settlement management effectively and practically and make them systematic and standardized.

(1)Management of casting quota calculation:The professional skills limit the management of the casting quota calculation. The technical department should be in charge of the design and quota calculation. The technical department should confirm the weight of the casting according to the three-dimensional design and facilitates other departments to weigh the casting. After finishing the design, the technical department sends the drawing to the production department and then delivers it to the casting makers in the production department. After the confirmation, statistics, and summary, the data will be sent to the production and financial department as evidence of the cost accounting and settlement.

(2)norm cost management:After the technical department finishes the quota statistics and summary, the production department should be responsible for the daily quota management. This is because the production department is the section that connects the factory and other departments. Besides, it also plays a role in receiving castings and the internal settlement receipts. This function serves as a connecting link between the production department and other departments. If the factory doubts the weight, they can ask the production department for a review. The production department will ask other departments to review. If there is an issue, the quota details that are sent to each department will be changed by the technical department and urge them to change the size and cast technology to meet the standards. Besides, the production department should also track the fluctuation of the real-time price in the market and report the information to the financial department.

(3)the quota calculation management:The financial department should be responsible for the external quota calculation management. First, settlement is the duty of the financial department. Second, it is helpful for the financial department to alter the price according to the market price. This process is to start with the production department and delivers the receipt of internal castings (types, materials, quantities of castings) to the financial department. Checks with the casting quota details issued by the technical and production department, then perform the account statistics and fund transfer according to the information provided by the production department according to the real-time price in the market.

(4)The quota calculation, management, and settlement of castings should be done regularly by the discipline Inspection commission or supervision department. The above departments should Hold casting price hearings to coordinate the supervise the bids and the selection of the suppliers. It is also required to audit and record the casting quota of the technical department, the actual storage of the production department, the casting settlement of the financial department, and the fund transmission conditions. Apart from this, it is also required to spot-check and assess the weight and quality of the castings.

(5)As it achieves the quota calculation, management, procurement, settlement, and supervises different departments, it effectively avoids the issues in the management process, lowers the procurement budget, and increases the profit.

5.Introduce the system of price competitiveness

(1)It should establishes a strict management system in the process of procurement and need to compare the price to choose the fine material so that the quality is ensured. besides, we also need to compare the purchase price of the other raw material accounts horizontally. The main suppliers should be the ones which have good spirit of contract and are trustworthy. They provide high quality products with reasonable price. moreover, the raw material can be obtained from the factory to know the price of and products and customer needs, so it reduces the unnecessary expenditure on dealers.

(2)Establishes a strict management system in procurement and compares the price for choosing the high quality material. Besides, we also need to compare the price when purchasing from the other raw material accounts horizontally. The major suppliers should be the ones that have a good spirit of contract and are trustworthy. They provide high-quality products at a reasonable price. Moreover, the raw material can be obtained from the factory to know the price of products and customer needs, so it reduces the unnecessary expenditure on dealers.

6.Establish the quality claim and assessment system

(1)The casting quality is related to the manufacturing equipment, technology, operators, etc. Products with many quality issues, like slag inclusion, air holes, and other defects. In the post-machining treatment and use processes, these defects are evident. They waste money spent on transportation, storage, and processing and affect the production cycle seriously or even lead to the main engine being broken and the shrinkage of the service life of the equipment. Thus, enterprises should be aware of the quality claim by establishing a quality tracing system so that the source, batch, and manufacturers of the problematic parts will be detected in time and process the claim according to the related casting supplier contract. This will drive the supplier to provide high-quality products and services. On the other hand, it increases the controllability of the suppliers.

(2)Enterprises must perform regular assessments about the suppliers and re-organize, screen, clean, and clean out the suppliers without competitiveness. This is the key to the improvement of quality and cost, which ensures the needs on quality, number, time, and price.

7.Establish the scientific price analysis and management system

(1)So far, with the fluctuation of the iron price, enterprises must need to establish a strict price management system according to the market information and trends. To get more information about the market price, we can achieve it through information technology and information network resources to compare the price. After confirming the bidding price, the policymakers to the buyers need to research the marketing supply and demand situation of raw materials. Carefully analyses the supply and demand contradiction, forecasts the market trend, makes procurement plans with the information of international and domestic markets, and then purchases within a reasonable storage range. At the downturn in the market price, reducing stocks is a wise decision, which can lower the procurement cost to a large extent.

(2)To sum up, lowering the cost of zinc alloy castings is an important method to reduce the cost of manufacturing products, which is simple and easy to operate with a healthy profit. Die casting factories should emphasize this.

With many years of experience in die casting, GREFEE can provide high-quality products with low cost and high market competitiveness. Try us to start your new project.

MORE BOLG

Categories

Try GREFEE now,for free

We keep your uploaded files confidential and secure.