Our Blog

Polishing Methods and Procedures of Die Casting Molds

Polishing Methods and Procedures of Die Casting Molds Posted on : April 26, 2022 By GREFEE The polishing in the die casting industry is different from that in the other industries (such as aluminum alloy die casting, zinc alloy die casting, and magnesium alloy die casting). Strictly speaking, the polishing should be called mirror finishing, which has high requirements for polishing quality, the planeness, smoothness, and geometrical accuracy of the surface finish. The requirement of surface polishing is only a smooth…

Reinforcement of materials and property introduction

Reinforcement of materials and property introduction of injection molding Posted on : April 26, 2022 By GREFEE Reinforcement of materials and property introduction of injection molding The injection molding technique contains a wide range of materials with different properties. We gonna talk about some common materials that you will see in injection molding, and advice for selecting materials for your design target, including more strengthened glass and fiber filling material, as well as the silicone resin and polyurethane materials for…

Die casting parts are everywhere in our daily life

Die casting parts are everywhere in our daily life Posted on : April 19, 2022 By GREFEE Die casting parts have always been close to us Die casting plays an indispensable role in the automotive industry, aerospace industry, telecommuting devices, and mechanical devices due to its outstanding efficiency, stable quality, and low cost for mass production. In this article, we gonna share some knowledge about die casting. Contact us to start a new project! 1. Characteristics of die casting Pressure casting…

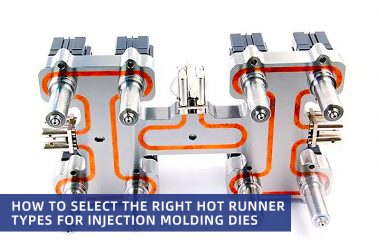

How to select the right hot runner types for injection molding dies

How to select the right hot runner types for injection molding dies Posted on : Apr18, 2022 By GREFEE The hot runner technology brings a revolutionary change into the mold market. More and more customers choose hot runners. The spread of this technology increases the pass rates of production and quality of products. It also minimizes the deformation issues of the products’ appearance. Meanwhile, it raises the production rates and achieves automation production, which expands the application range of the…

GREFEE has more standards for mold machining

Except for ISO9001, GREFEE has more standards for mold machining Posted on : April 15, 2022 By GREFEE Except for ISO9001, GREFEE has more standards for mold machining In GREFEE, all production must strictly follow the ISO 9001 quality control system. However, we have more than that. With more than 20 years of experience, we developed a more rigorous production standard for the details in production, which improves our production rates significantly. Besides, its convenient operation reduces the occurrence of mistakes.CONTACT…

Property intoduction of materials

Things you should know for a good selection of material Posted on : Apr14, 2022 By GREFEE GREFEE has a strict material selection standard. Most materials that we use are from well-known material suppliers, and they come with material reports. Below is some knowledge of the material that you want to know. Begin with a new project with GREFEE.CONTACT The metal material is often divided into three types, which are black metal, nonferrous metals, and special metals. Black metal, also known…

CNC machining from prototype to small volume production

Things need to know about CNC machining from CNC rapid prototyping to small volume production Posted on : April 13, 2022 By GREFEE Things need to know about CNC machining from CNC rapid prototyping to small volume production A great mold designer should also work closely with the frontline workers and have many questions from the considering and communication about the plan, especially considering how to make the components easier to machine. A perfect plan comes from the continual exploration process. Based on…

Requirements for CNC copper parts design

Requirements for CNC copper parts design, manufacturing, and surface treatment Posted on : Apr12,2022 By GREFEE Requirements for CNC copper parts design, manufacturing, and surface treatment Copper is known for its naturally beautiful, glossy, and extensive application. After machining, many products are as beautiful as arts. Copper can use to make utensils, decorations, electric energy equipment parts, and even jewels. Besides, it also has great elasticity and electrical performance, which is suitable for components with high complicities, like EDM electrodes….

Better making aluminum alloy die casting

Details should to know for better making aluminum alloy die casting Posted on : April 12 , 2022 By GREFEE Details should to know for better making aluminum alloy die casting The fusing and pouring steps are the main parts of aluminum alloy die casting. Strictly controlling the whole process of these two steps plays a critical role in preventing pinholes, impurities, undercasting, cracking, air holes, shrinkage porosity, and more. Molten aluminum has a great tendency of the absorption of hydrogen,…

Working principles of CNC precise machining parts

Working principles of CNC precise machining parts Posted on : April 12 , 2022 By GREFEE Control system for CNC precise machining parts Generally, the machine tool works by following the orders which are programmed by numbers to make it automatically start and stop, turn and change speed. It can automatically change the feeding speed, direction, and machining route. Can select tools and can adjust the engagement according to the size of the tools and can complete all auxiliary actions that…

Underfeeding issue in die casting products

causes analysis and improving methods of underfeeding issue in die casting products Posted on : Apr11, 2022 By GREFEE What is underfeeding in die casting? The surface of the die casting parts sinks due to the mold damages, collisions, and other reasons. The irregular shapes and changeable locations can be improved by welding. causes of underfeeding in die casting process Mold manufacturing reasons, overfeeding in the local cavity or wrong sizes The mold is invalid and there is checking and heavy…

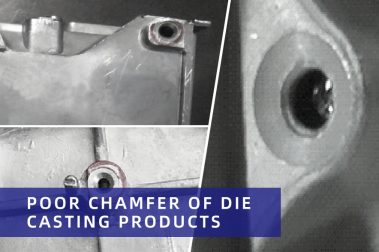

Chamfers in die casting parts

Causes analysis and improvement methods of chamfers in die casting parts Posted on : Apr11, 2022 By GREFEE what is chamfer in die casting? In the CNC post-treatment of die casting parts, the chamfers are might be too deep to too shallow or even omitted. causes for poor undercuts in die casting machines? wrong size for molding core/uncontrolled mold core loose or has wear issues of CNC machining jigs, CNC programs, or issues of operators. how to improve poor chamfering? Double…