Our Blog

Conformal waterway technology in hot runners

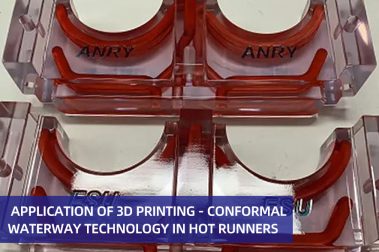

Application of 3D printing – conformal waterway technology in hot runners Posted on : April 9, 2022 By GREFEE Application of 3D printing – conformal waterway technology in hot runners. It is well-known that mold is fundamental to the manufacturing industry. The improvement of mold technology can effectively enhance the core competitiveness of enterprises and the nation’s critical businesses. To better meet the needs of consumers, the enterprises have been re-invented themselves and strictly controlled the quality. As the products update…

3D printing raise the manufacturing capacity

How does 3D printing raise the manufacturing capacity of high standards and high-added-values molds? Posted on : April 9, 2022 By GREFEE Through the 3d printing cases made by GREFEE in the last year, we know that the cases of the application of the 3C electronics field raised sharply. Among so many cases, we selected one, wireless earbuds charging box, which is not as simple as it looks AirPods on the market Earbuds look simple but are expensive. It increasingly owns…

High-gloss traceless injection molding technology

High-gloss traceless injection molding technology Provides perfect surface quality for your plastic products. Posted on : April 8, 2022 By GREFEE High gloss is a typical manifestation of traceless injection molding but is not the whole of it. GREFEE has many years of experience in manufacturing high gloss mold and traceless injection molding. Our main businesses are home appliances, external decorations of electronic products, like external panels of DVD / DMR / BD / BR / PDVD and other audio-visual players,…

Energy Consumption Saving in the Heat Treatment

Energy Consumption Saving in the Heat Treatment in Die Casting Industry Posted on : Apr 7, 2022 By GREFEE Energy Consumption Saving in the Heat Treatment in Die Casting Industry Some new techniques are being widely used for manufacturing molds, such as EDM, forming grinding, linear cutting, etc. These technologies can effectively solve the deformation issue due to the heat treatment or the machining of complex mold. Heat treatment is generally the last step of mold machining. The mold accessories that…

High precision machining mold

High precision machining mold,GREFEE is always moving forward. Posted on : April 7, 2022 By GREFEE Molds play an indispensable role in many industries, like electronic consumers, automobiles, airplane making, etc. In recent years, mold technology has achieved remarkable progress. With more and more enterprises begin to purchase high-precision mold. The mold technology development and quality are essential factors for domestic mold manufacturing development. Utilizing high-speed machining can efficiently improve the production rate, accuracy, and service life. Thus, it replaces the…

Zinc alloy die casting mold machining

Zinc alloy die casting mold machining Posted on : April 7, 2022 By GREFEE 1. Zinc alloy die casting mold machining Zinc alloy die casting mold making refers to the forming and blank making. It also includes shear mold and die-cutting mold. In most cases, the mold has an upper mold, and a lower mold with a steel plate is in between to realize the material formed by the press machine. When the machine opens, a part will be obtained as the shape…

Advantages of CNC machining.

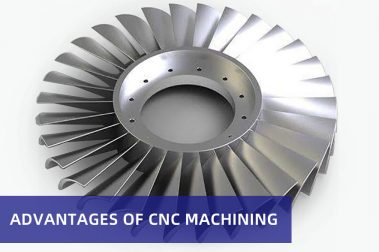

Advantages of CNC machining CNC processing mode with high quality and repeatability Posted on : April 6, 2022 By GREFEE CNC machining refers to a manufacturing method operated by the numerical control lathe. Generally, the process of CNC machining and conventional lath machining is similar. They are both based on the operation by the digital information and tools movement, while it also includes some changes. CNC machining is a method of high-efficiency automation, which is applicable for products with complex and…

The application of 3D printing in the laryngoscope mold

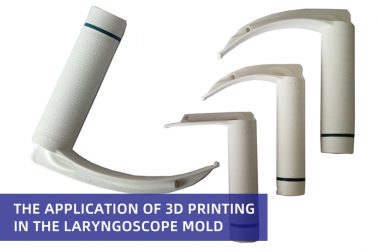

The application of 3D printing in the laryngoscope mold Posted on : March 31, 2022 By GREFEE Medical care used tools have rigorous requirements on accuracy. Thus, it has higher requirements for the accessories production of medical used machines. In the production of the accessories of medical devices, there is no tolerance for the surface quality, accuracy, and hygiene, from the hyperbaric oxygen chambers to hearing aids, anesthesia laryngoscopes, medically used buttons, and other injection molding products. If it is required,…

Types of Injection molding

Before you initiating your new project, you need to know the types of injection molding. Posted on : March 24, 2022 By GREFEE There are many ways to classify the injection molding, in which it is classified into few types according to the difference. (1) classified by the material, there are thermoplastic injection mold and thermosetting plastic injection mold. a. Generally, injection molding technology suits for both thermoplastic and multiple thermosetting plastic. b. In the injection molding process of thermoplastic molds,…

The Calculation Formulas for Injection Molding

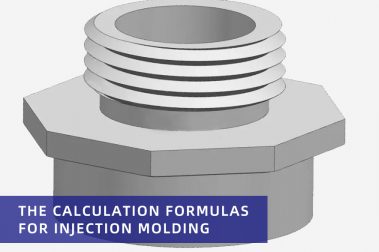

The Calculation Formulas for Injection Molding Posted on: March 23, 2022, By GREFEE Part 1 Clamping tonnage F (TON) Formula: F=Am*Pv/1000 Clamping tonnage: TON Am: Mold Cavity Projected area: CM2 Filling Pressure: KG/CM2 Generally, the plastic material filling pressure range is 150-350KG/CM2) Good flowability takes bottom values, poor flowability takes top values. Injection Pressure= filling pressure/0.4-0.6 For example: Mold Cavity Projected Area 270CM2, Filling pressure 220KG/CM2 Clamping tonnage =270*220/1000=59.4TON 2. Injection Pressure Pi(KG/CM2)Formula: Pi=P*A/Ao that is: Injection…

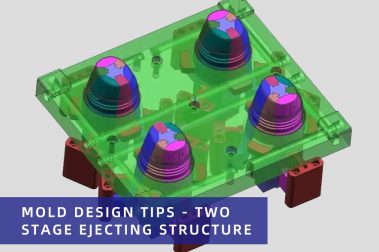

Mold design Tips – Two-Stage Ejecting Structure

Mold design Tips – Two-Stage Ejecting Structure Posted on : March 24, 2022 By GREFEE Generally, when taking the product out from the mold, no matter it applies a single or multi-parts ejecting structure, the ejection should be finished once. However, due to the specific shaped products or requirements of volume production, a two-stage ejecting structure makes it possible to carry out ejection two times, which is very continent in cases in which the molded item can not be taken out old…

Shrinkage depression of die casting products

Causes analysis and improvement methods of shrinkage depression of die casting products Posted on : March 24, 2022 By GREFEE To learn more problems and preventions of die casting, click to check it out. Undercasting Cold Shut Mold Sticking Cracking Flow Marks Deformation Strain Ejector pin Marks Dented Lamination Burrs Shrinkage depression Bulges Deformation Fissure Discolored Mottles Bubbles Washout What is shrinkage depression in die casting? When die casting products contract when they are cooled, during which the outer layer adheres to…