Our Blog

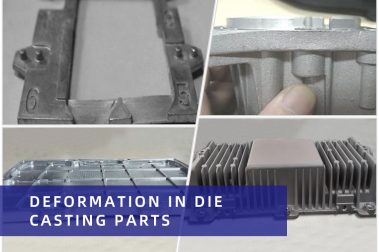

Deformation in die casting parts

Causes analysis and improvement methods of deformation in die casting parts Posted on : March 23, 2022 By GREFEE To learn more problems and preventions of die casting, click to check it out. UndercastingCold ShutMold StickingCrackingFlow Marks DeformationStrainEjector pin MarksDentedLamination BurrsShrinkage depressionBulges Deformation FissureDiscolored MottlesBubblesWashout What is deformation of die casting products? The casting deformation is caused by the geometry inconsistent with the drawing, which is featured by warpage, overall deformation or local deformation. Causes: improper casting structure design causes uneven shrinkageMold…

Cracking in die casting products

Causes analysis and improvement methods of cracking in die casting products Posted on : March 23, 2022 By GREFEE To learn more problems and preventions of die casting, click to check it out. Undercasting Cold Shut Mold Sticking Cracking Flow Marks Deformation Strain Ejector pin Marks Dented Lamination Burrs Shrinkage depression Bulges Deformation Fissure Discolored Mottles Bubbles Washout What is cracks in die casting products? The casting body is damaged or disconnected, which forms the filamentous crevices. It has two types, penetrable…

Ejector pin marks in die casting products

Causes analysis and improvement methods of ejector pin marks in die casting products. Posted on : March 23, 2022 By GREFEE To learn more problems and preventions of die casting, click to check it out. Undercasting Cold Shut Mold Sticking Cracking Flow Marks Deformation Strain Ejector pin Marks Dented Lamination Burrs Shrinkage depression Bulges Deformation Fissure Discolored Mottles Bubbles Washout What is ejector pin marks of die casting parts? The casting surface has embossing due to the cavity bumping and the assembly…

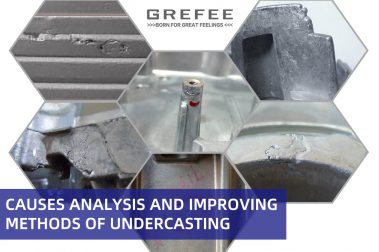

Undercasting die-casting products

Causes analysis and improvement methods of undercasting die-casting products Posted on : March 22, 2022 By GREFEE To learn more problems and preventions of die casting, click to check it out. Undercasting Cold Shut Mold Sticking Cracking Flow Marks Deformation Strain Ejector pin Marks Dented Lamination Burrs Shrinkage depression Bulges Deformation Fissure Discolored Mottles Bubbles Washout What is die casting undercasting? In die casting, the place that is filled incompletely during the process or places that are not close enough are…

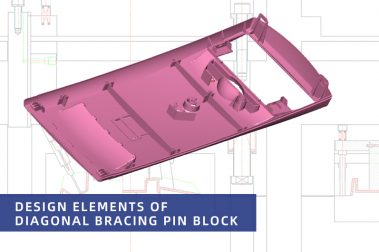

Things you need to know about how to design a slide

Things you need to know about how to design of mold slide. Posted on : March 11, 2022 By GREFEE Undercuts treatment Movement principles & design elements of diagonal bracing pin block Undercuts treatment uses the mold opening movement and ejection force to causes the tendency of relatively motion between angle pin and slider. There are two movements to make it separate from the undercut : mold opening direction & horizontal direction. As the below pic shows: in the pic: β=α+2°~3°(avoid any parts contacts or blocks…

Design tips for die casted parts

Design tips for die casted parts Posted on : March 9, 2022 By GREFEE Concept Die casting is a technology of manufacturing metal parts that liquid metal or semi-liquid metal fill the die casting cavity at a high speed under high pressure to get a metal part after solidification under pressure. The outstanding features of die casting technology are high pressure, high speed and high temperature. Advantages High production efficiency, it’s easy to achieve mechanization and automation in the production process. Die casted parts have high dimensional precision and high surface…

Test mold injection molding

Test mold injection molding processing guide and machining setting principles Posted on : March 9, 2022 By GREFEE This guide aims to better helping technological team members grasp knowledge of test mold injection knowledge and skills to quickly learn the guidelines of machining setting, Can quick identify mold defects and continue improving Helps you to quickly get involved into the injection molding production domain Part1:Preparation before mold testing Part2:Mold dry run Part3:Injection volume formula Part4:Injection balance Part5:Clamping tonnage formula Part6:Ideal clamping…

High pressure die casting

IThings you need to know about high pressure die casting. Posted on : March 3,2022 By GREFEE High-pressure die casting is known as a metal die-casting technique, which injects the molten metal by high pressure in the die casting machines and then injects the metal fusion into the mold cavity. The mold makes of fine steel. Its working principle is as similar as that of injection molding. Most die casting components are iron-free, for instance, Zinc die casting, Copper die casting,…

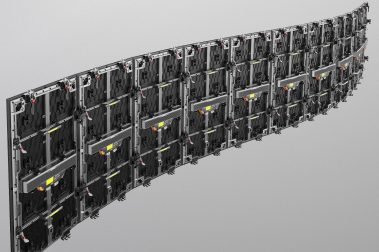

LED die casting

Die casting technology can also be used for LED products Posted on : March 4, 2022 By GREFEE These days, small spacing LED has quickly occupied the market. As the new focus and new driven force of the domestic LED screening industry, the rapid development of the small spacing LED also benefits its peripheral products in the same way. One of the products is the LED die casting box. The conventional iron box has many drawbacks, for instance, heavy and low…

Design tips for plastic parts

Design tips for plastic parts Posted on : February 16, 2022 By GREFEE Plastics: main composition of plastics are carbon, oxygen, hydrogen, nitrogen and other organic or inorganic elements. They’re solid but can be molten liquids in the manufacturing process. Melting by heating, flowing by pressure, and solidified by cooling make the materials present various shapes, such large numbers and changeful material group are called plastics. Characteristics of plastic materials: Low intensity and low toughness. Abundant raw materials, low cost. Easy-molding,…

Die casting case for automobile gearbox of Ford

Die casting case for automobile gearbox of Ford Posted on : February 14, 2022 By GREFEE A set of successful research and development in die casting moulds is a huge system engineering which integrated with varieties of technologies which include materials, heat treatment, mould design, die casting technology, processing technology, assembly technology, production management and quality control, etc.Customized die casting solution is a very important part, and the reasonability of technology directly affecting the part quality and its post production. …

Introduction to mold polishing

Introduction to mold polishing Posted on : February 17, 2022 By GREFEE List Ⅰ.Objectives of mold polishing. Ⅱ.Issues caused by poor mold polishing. Ⅲ.Mold polishing classification. Ⅳ.Tools & machines in mold polishing. Ⅴ.Common used polishing tools. Ⅵ.Dos and don’ts of mold polishin. Ⅶ.Factors affect the quality of mold polishing. Ⅰ.Objectives of mold polishing. With plastic material has been utilized in different industries, the requirements of mold polishing can reach up to the degree of mirror finishing. The guidelines of mold polishing…