Our Blog

Introduction to mold polishing

Introduction to mold polishing Posted on : February 17, 2022 By GREFEE List Ⅰ.Objectives of mold polishing. Ⅱ.Issues caused by poor mold polishing. Ⅲ.Mold polishing classification. Ⅳ.Tools & machines in mold polishing. Ⅴ.Common used polishing tools. Ⅵ.Dos and don’ts of mold polishin. Ⅶ.Factors affect the quality of mold polishing. Ⅰ.Objectives of mold polishing. With plastic material has been utilized in different industries, the requirements of mold polishing can reach up to the degree of mirror finishing. The guidelines of mold polishing…

Introduction to Aluminum Passivation

Introduction to Aluminum Passivation Posted on : February 16, 2022 By GREFEE Aluminum Passivation refers to aluminum materials experiencing a type of oxidation treatment by the strong oxidation and electrical chemical methods to make the surface inactive. It is a method that can reduce the oxidation level of the aluminum surface and slow down the speed of surface corrosion. Besides, an active metal or alloy, the chemical activeness is significantly reduced and then turns into noble metal condition is called passivation. It is…

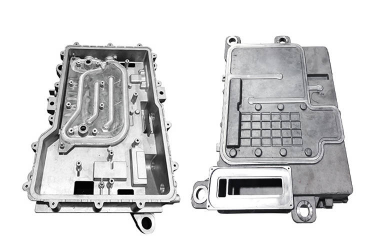

Applications of die casting parts in new energy cars

Applications of die casting parts in new energy cars Posted on : February 16, 2022 By GREFEE With the proliferation of new energy cars, the automobile lightweight and integrated die casting parts increased, so companies who have put their foot in these two areas will be benefited. The area is affected by many factors, such as higher standards to the fuel vehicles’ fuel consumption, higher subsidy threshold of electronic motorcycles, and the pressure from store credits of new resources cars. The complete…

Threaded plastic products are seen everywhere in our daily life

Threaded plastic products are seen everywhere in our daily life Posted on : February 15, 2022 By GREFEE Threaded plastic products are seen everywhere in our daily life, such as bottle caps, connecting threads, etc.The thread injection molding products are everywhere in our daily life which can be found easily.The Injection molding thread is widely used in our life. How to fabricate injection molding plastic parts containing ingenious threads elements?Not only the part design, but also the fabricating needs to be…

Die casting technology supported 5G products

Die casting technology supported 5G products Posted on : February 14, 2022 By GREFEE The development of 5G brings new requirements for the internet infrastructure. The number of its base and cost is over two times that of 4G. According to the reports, mobile terminal, automobiles, industrial internet, medical health, entertainment, five major developed industries will be benefited in advance. The high demand of 5G communication bases and wave filters also stimulate the die casting suppliers of the whole industrial chain. The parts…

Introduction of stainless steels commonly used in cnc machining

Introduction of stainless steels commonly used in cnc machining Posted on : February 12, 2022 By GREFEE Stainless steel has mirror-like brightness, as well as hard and cold sensation. It is an avant-garde decorative material with diverse using advantages, like orrosion resistance, formability, compatibility and toughness. Stainless steel is used in many industries such as heavy industry, light industry, household goods and architectural decoration. StaStainless acid-resistant steel is what we called stainless steel. It contains stainless steel and acid-resistant steel whose functions are…

Cases for soft rubber mold

Cases for soft rubber mold Posted on : February 10, 2022 By GREFEE Soft rubber material is a collective name for soft materials. Its hand feeling is soft and mild,. There are many types of soft rubber materials which include rubber and plastics, such as rubber, silicone rubber, TPU, TPE, soft PVC,etc. Main properties of soft rubber products that we mainly concerned include: hardness, elasticity, corrosion resistance, wear resistance, cracking, coloring performance, high (low) temperature resistance, cost and processing technology, etc….

Inspection standards for CNC machining

How to make perfect products with CNC machining, tips for inspection you need to know! Posted on : January 19, 2022 By GREFEE No matter which type of mater it is, metal or plastic, CNC machining can make it for for you. However, How do we evaluate whether the requirements of CNC machined products were met?This article will introduce GREFEE’s inspection specifications for CNC machined parts. To achieve 100% qualified products made from CNC machining, GREFEE sets the inspection specifications for CNC machined parts…

Factors affecting CNC machining

Factors affecting CNC machining: The CNC machining tips you must know? Posted on : January 15, 2022 By GREFEE The working performance and service life of mechanical products are always directly related to the machining quality of components and the assembling accuracy of products. The machining quality of components is the foundation of the whole product quality. Studying on machining quality aims to discover the regularity of machining errors.Then study and analyze the influence of various factors on machining error. This article will illustrate all kinds of…

Inspection standards

Tips for the appearance of injection molded part inspecting The quality evaluation of you plastic products. Posted on : January 11, 2022 By GREFEE Injection molding is the most common manufacturing technology in industrial fields. Injected products not only have high requirements of dimensions, but also even have higher requirements on its appearance. Common defects of injection molding products such as: shrinkage on product surface, welding marks, flash, eject marks, etc. Those are important factors affecting the use of products. GREFEE…

Insert mold in injection mold service

Insert mold in injection mold service Posted on : Dec 18, 2021 By GREFEE Insert mold generally is a kind of mould that make nuts, metal parts or hard plastic parts fixed inside cavities for injection molding. Insert nuts injection molding: nuts material can be stainless steel, copper, bronze and steel, generally copper nuts are commonly used. Copper is easy to knurl, which helps nuts and plastics splice better. The tolerance of nut inner bores should be controlled within 0.02mm, otherwise…