Our Blog

Methods to Solve the PC Injection Molding Issues

Methods to Solve the PC Injection Molding Issues Posted on : Aug 2 , 2022 By GREFEE There are many factors which affect the quality of PC products in different aspects. As long as you grasped the following factors, the quality issues can be improved significantly. Raw material The material used for injection is the transparent and colorless aggregate. Some of them are colored in mild yellow. The relative molecular weight is 2.3 × 10,000 · 3.2 × 10,000. Before…

What should be paid attention to in CNC machining

What should be paid attention to in CNC machining of magnesium alloy parts? Posted on : July 15 , 2022 By GREFEE Definition of magnesium alloy Magnesium alloy is an alloy based on magnesium and also includes other elements, which has high strength, large elastic modulus, good heat dissipation and shock absorption, greater impact load bearing capacity than aluminum alloy, and excellent resistance to organic and alkali corrosion. CNC machining service of GREFEE metal cnc Main application industry of magnesium…

Material selection of the injection molding automotive parts

Material selection of the injection molding automotive parts Posted on : July 18 , 2022 By GREFEE Jump to Section >>General plastic >>Engineering plastics >>Special plastics The raw material has a broad range, which is divided into the interior, exterior and functional parts in terms of the automotive plastic injection molding parts. The plastic is classified into three types, general plastics, engineering plastics and special plastics according to the various properties. General plastic It generally refers to plastics with large production…

PC Injection molding process and screw selection

PC Injection Molding Process and Screw Selection Posted on : July 21 , 2022 By GREFEE The PC material has high strength, good transparency, low molding shrinkage rate, and high process ability, which is widely used in electronic devices and industrial parts fields. PC materials has excellent features with high transparency and impact rigidity, and deformation resistance, wide using temperature range. PC injection molding products are being used a broad range of products since it provides remarkable aesthetic value and…

Precision injection molding solutions

Precision injection molding solutions Posted on : Aug 15 , 2022 By GREFEE What is precision injection molding? The high precision injection molding refers to an injection molding method of which the dimensional repetition accuracy of the injection molding parts is very high, resulting in hard to achieve the requirements with general injection molding machine and ordinary injection molding processing. What distinguishes the high precision injection molding from the ordinary injection molding is that the technology of using precision plastic parts…

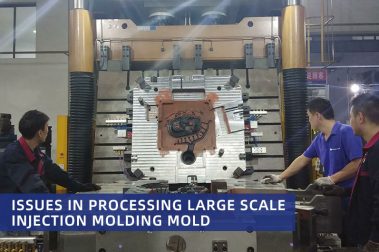

Issues in Processing Large Scale Injection Molding Mold

Issues in Processing Large Scale Injection Molding Mold Posted on : July 25 , 2022 By GREFEE Nowadays, the demand for large-scale injection molding mold is increasing. From the flat screen TV to car dashboard, the designer always seeking the improvements in the dimension and complexity of the mold making. However, not every manufacturer can make large scale injection molding mold as it includes many difficulties and is hard to process. Issues of large scale injection molding mold The shapes…

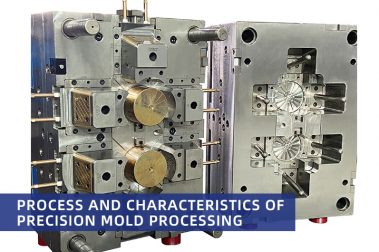

Process and Characteristics of Precision Mold Processing

Process and Characteristics of Precision Mold Processing Posted on : July 27 , 2022 By GREFEE If you are looking for high precision injection molding, you need a set of the high precision mold. The high precision mold suppliers generally can meet your processing requirements. Before this, you need to communicate about the project to provide the drawing to the suppliers. A set of mold is composed of multiple components and the quality is directly related to the mold quality. The…

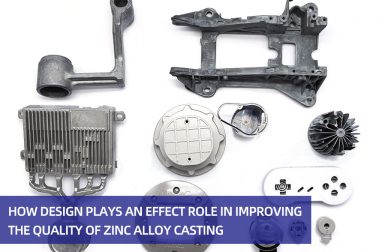

How design plays an effect role in improving the quality of zinc alloy casting

How Design Plays an Effect Role in Improving the Quality of Zinc Alloy Casting Posted on : July 11 , 2022 By GREFEE Zinc alloy die casting molds are important process equipments in the zinc alloy die casting production. During the production, the liquid metal solidified in the die casting molds and finally being formed into the zinc alloy die casting parts. Its shapes, dimensions, quality and efficiency are all related to the die casting molds. Thus, a proper design is…

5-axis CNC machining — Lamborghini grille

5-axis CNC machining — Lamborghini grille Posted on : Aug 29, 2022 By GREFEE Lamborghini is one of the most luxurious sports cars. It was a great honor for GREFEE to have an opportunity to work with the R&D team to produce the grille for its Urus model, which was 150 sets. The team from Lamborghini required the main body be produced by 5-axis CNC machining, and the bottom to snap via assembly. The requirements for the surface finish was high…

Production mode and surface treatment process of aluminum Radiator

Production Mode and Surface Treatment Process of Aluminum Radiator Posted on : July 14 , 2022 By GREFEE Production mode and surface treatment process of aluminum heat sink There are mainly three ways to produce aluminum alloy heat sink, including the extrusion process, die casting process, CNC machining Introduction to extrusion production process of aluminum profile radiator: 1. For the aluminum extrusion mold with high density teeth and large tongue ratio, the first aluminum rod must be a 150-200mm short…

What do you require to check about the aluminum alloy casting?

What do you Require to check about the Aluminum Alloy Casting? Posted on : July 20 , 2022 By GREFEE 1.Visual inspection Processing an analysis about the surface quality of the aluminum alloy castings visually to see whether there is pattern, flow mark, depression and shrinkage, deformation, cold shut, underfeeding, discoloration, or spots. Also, the inspection can be carried out with the magnifier with being magnified more than 5 times. 2. Dimension inspection A .Use vernier caliper to check the wall thickness and…

Four Main Factors of High Quality Zinc Alloy Die Casting

Four Main Factors of High Quality Zinc Alloy Die Casting Posted on : July 12, 2022 By GREFEE Die casting products is widely used in many industries. Most alloys are suitable for die casting. The physical and mechanical property of different alloys is heterogeneous, which provides convenience for the design of products. The most common die casting includes zinc die casting and aluminum die casting. Other than that is magnesium, zinc-aluminum, copper, tin and lead alloys. Zinc alloy die casting has…