Our Blog

Zinc Alloy Electroplating Processing

Zinc Alloy Electroplating Processing Posted on : July 22 , 2022 By GREFEE Jump to Section >>Electroplating process >>Characteristics of zinc ally electroplating >>Common issues summary Electroplating is a common treatment method for metal surface. Metal plating also needs professional processing process to make the surface beautiful and qualified. Common parts that are used for plating on zinc alloy, plating on aluminum alloy, plating on magnesium alloy, plating on copper alloy, etc., have gold plating, silver plating, zinc plating, nickel plating, chrome plating, etc. Electroplating…

How to Fix the Shrinkage Deformation

How to Fix the Shrinkage Deformation of Injection Molded Parts Posted on : July 30 , 2022 By GREFEE It is inevitable to meet defects like warping when designing injection molded parts. So how to fix the warping? First, we must understand what causes the injection molding parts warping? After knowing the fundamental of the basics, we can start from four aspects, which are plastic materials, plastic parts design, mold structure and molding process. Certainly, the prevention is more important…

Common Issues in the Hard Anodizing

Common Issues in the Hard Anodizing Posted on : July 28, 2022 By GREFEE Common Issues in the Hard Anodizing Hard anodizing is a kind of hard anodized with higher requirements for the wear resistance of the oxide film of the workpiece, which is categorized into: (1) sulfuric acid hard anodizing method; (2) oxalic acid hard anodizing (3) mixed acid hard anodizing. Without specified, it often refers to sulfuric acid hard anodizing. hard anodizing principles 1. Cathodic reaction:4H+ +4e=2H2↑ 2. Anode reaction: 4OH --…

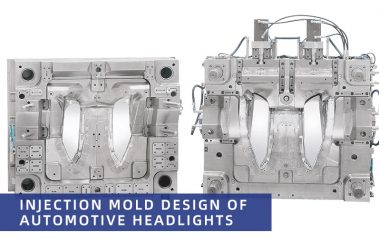

Injection Mold Design of Automotive Headlights

Injection Mold Design of Automotive Headlights Posted on : Nov 28 , 2022 By GREFEE Injection Mold Design of Automotive Headlights Injection mold design As the auto lamp mold is large scale mold and its parting surface is complex, many injection molding parts manufacturers in the world utilize the integrated structure in the injection molding products and molds, which means the fixed mold plate a of the mold is the fixed mold forming part, and the movable mold plate B of the mold is…

Producing die casting mold with the correct material

Producing die casting mold with the correct material. Posted on : July 6 , 2022 By GREFEE What is die casting mold? The die casting mold is one tool specifically used to cast the metal parts on the die casting die forging machine to complete die casting technology tool. The basic process of it is to fill the mold cavity with the liquid metal at a high or low speed. As the mold has flexible cavity surfaces and with the…

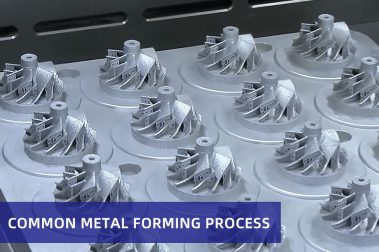

Common metal forming process

Common metal forming process Posted on : July 4 , 2022 By GREFEE One thing that manufacturers really concern is the metal material forming method, which is a key part in the parts design, and also an essential factor in material processing. Below are few current used forming methods. Casting Liquid metal is poured into the casted mold cavity that is similar to the shape and size of the parts. After it is solidified, we can obtain the blanks and…

Manufacturing Methods of Rapid Tooling

Manufacturing Methods of Rapid Tooling Posted on : June 29 , 2022 By GREFEE Manufacturing Methods of Rapid Tooling Rapid tooling is a type of tool used to produce products with specific shapes, size and surface accuracy, which is mainly adopted in the large volume production. Even though the production and fabrication cost is high, the cost of each product decreases significantly due to the large volume production. Advantages of rapid tooling processing 1. Custom moulds for personal applications are…

Purpose of mold testingprior to mold manufacturing and delivery

Purpose of mold testingprior to mold manufacturing and delivery Posted on : July 9 , 2022 By GREFEE Purpose of mold testing prior to mold manufacturing and delivery Checking whether the injection mold, product structure, plastic raw materials and color masterbatch (toner) meet the requirements of development and design to ensure the mass production processing effectively. This article mainly focuses on the injection mold. Range Applicable to injection molding production and manufacturing, injection molding technician, and injection molding rack technician for mold trial operation. Responsibilities…

Things you should pay attention to in the plastic electroplating.

Things you should pay attention to in the plastic electroplating. Posted on : June 27 , 2022 By GREFEE Can plastic be electroplated? The answer is Yes! Compared to the metal parts, the electroplating plastic parts not only can achieve a great metal texture but also reduces the weight of products. With improving appearance of plastic and meeting the need of decoration, it also enhances the properties in the electric, thermal, and corrosion resistance. However, the material selection for electroplating…

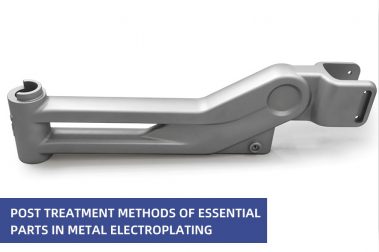

Essential parts in metal electroplating

Post treatment methods of essential parts in metal electroplating Posted on : July 1, 2022 By GREFEE In the mechanical design, electroplating is a common surface treatment processing. Let’s take a look some common used metal electroplating processing. what is metal plating Electroplating utilizes the principles of electrocysis by coating a thin layer of other metal or alloy on the surface of a different metal to prevent the metal oxidation, such as corrosion to enhance its wear resistance, electric conductivity, reflection,…

Problems you might meet in die casting

Problems you might meet in die casting Posted on : June 8, 2022 By GREFEE The die casting technology is widely used in many industries, such as automotive making, electronic engine shells, hardware, mechanics, aerospace, LED, etc. it is also a rigorous production process, which is inevitable to meet various troubles. With many years of experience, GREFEE has accumulated rich experience in die casting. This is an introduction to the common problems in die casting with solutions. You can also contact…

Details you should know for the quality control

Details you should know for the Quality Control of Zinc die castings Posted on : July 7 , 2022 By GREFEE The zinc alloy die castings is increasingly becoming popular among zinc alloy die casting parts manufacturers. Since the requirements for the use performance are also increasing even though the physical quality of zinc alloy has been quite stable. To meet the requirements of customers, die-casting suppliers uses high-purity zinc alloy ingots with sticky process control system. In addition, the requirements for…