Understand GREFEE’s sheet-metal processing service

- No MOQ, whatever one piece or large quantities, we can manage it quickly.

- 10ys+ manufacturing experience in electrical enclosure

- Provide comprehensive sheet metal processing service and surface treatment service

- 3 numerical control laser cutting machines, 9 precision stamping machines

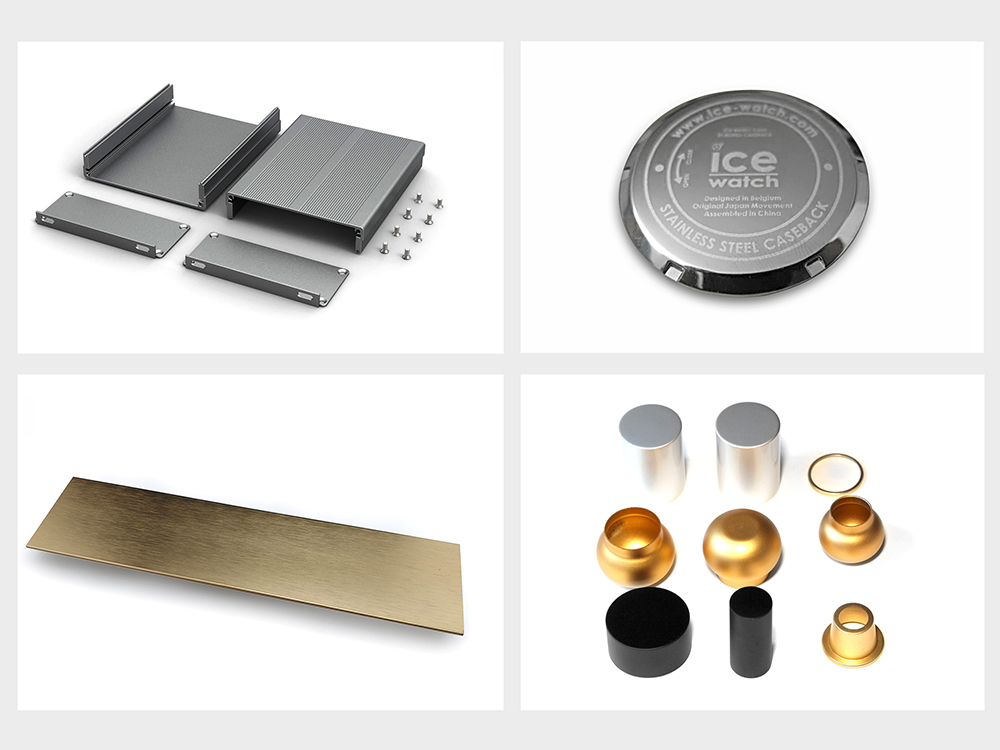

- Support sheet metal processing in many kinds of metal shells

- Provide IP65/IP66 reports of all kinds of dimension inspection, environment testng and electric shells

- 7*12 online engineers support your business

- Contact us, we’ll provide you quotation and product assessment for free

- Click right side video and have a look at our sheet metal working factory

Our Merits

10ys+ industry experience

made urgent part within 1 day

full-dimension report valid

High precision sheet metal

advantage of most economical price

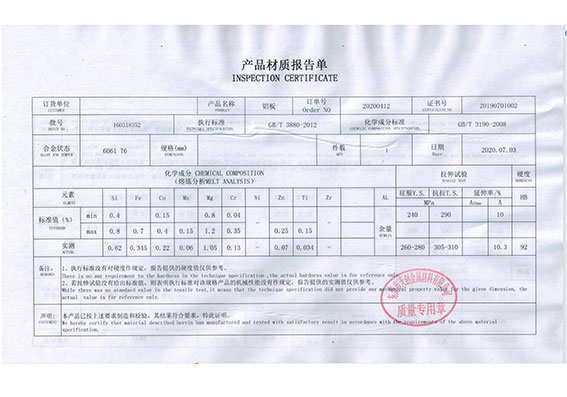

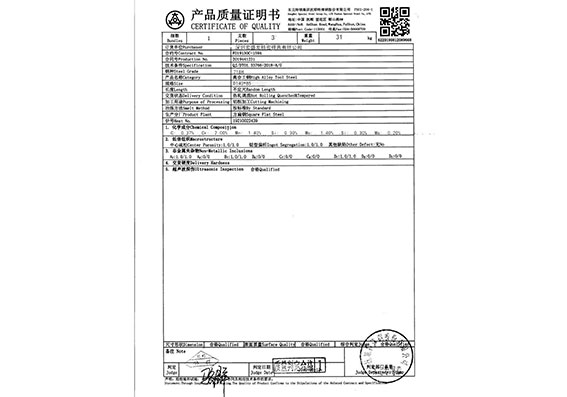

provide material authentication and certificate of qualification

GREFEE customized sheet metal processing flow

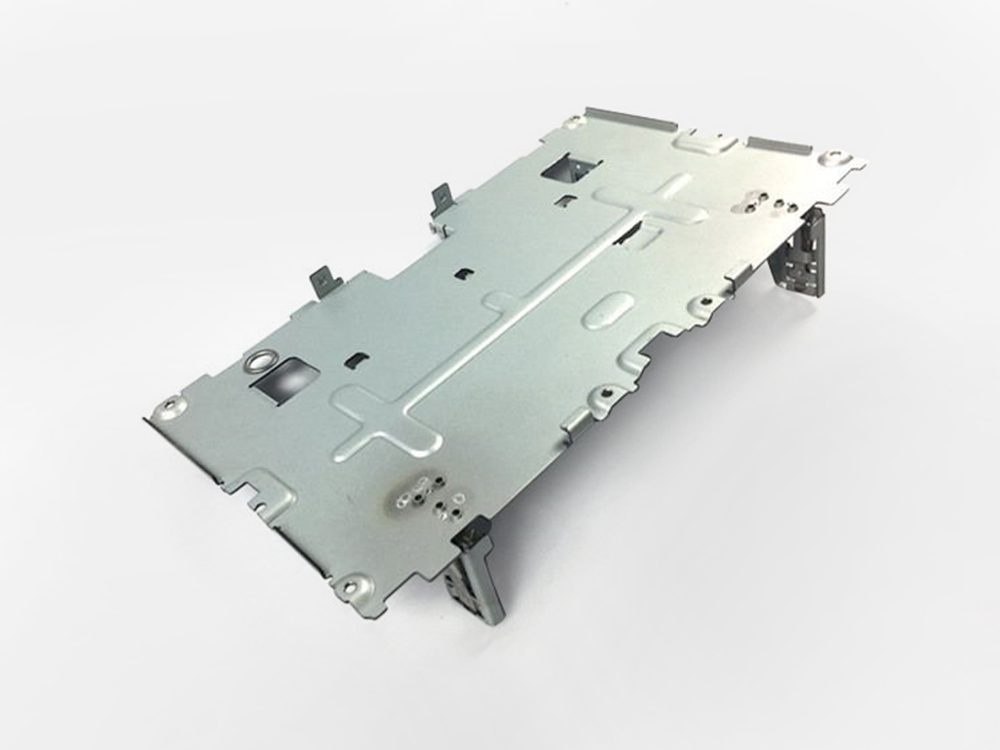

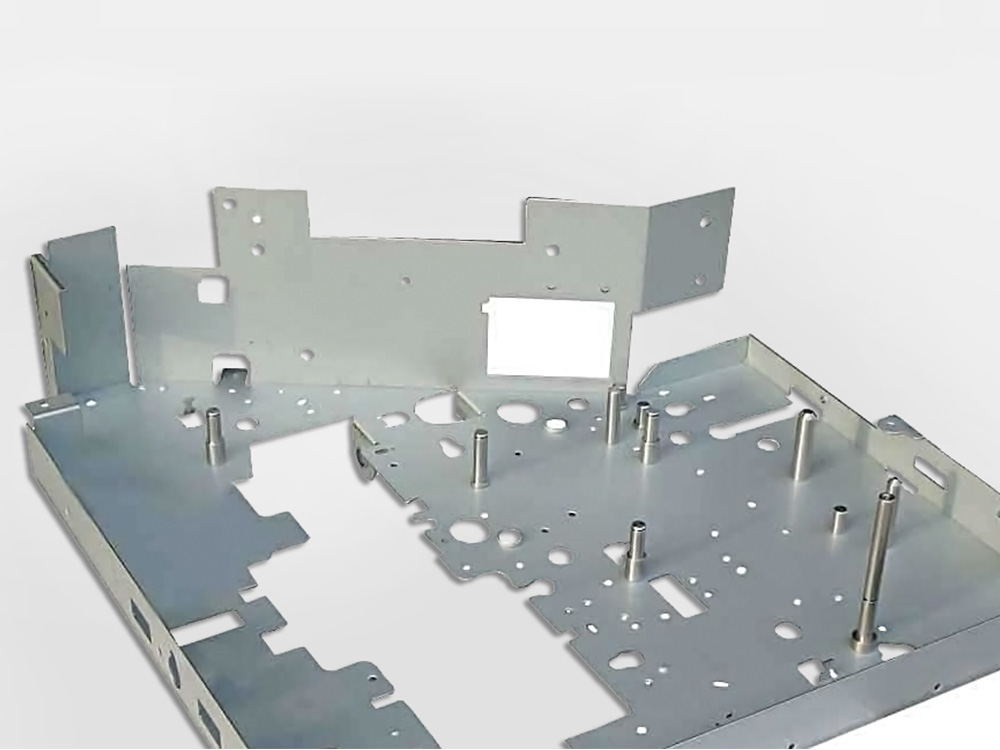

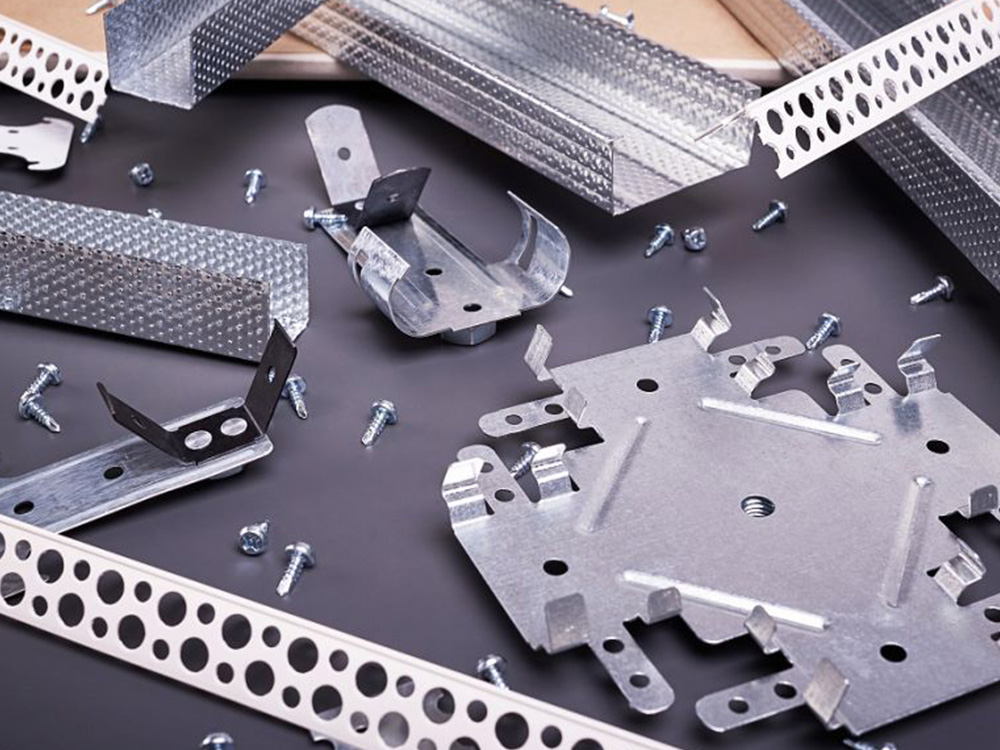

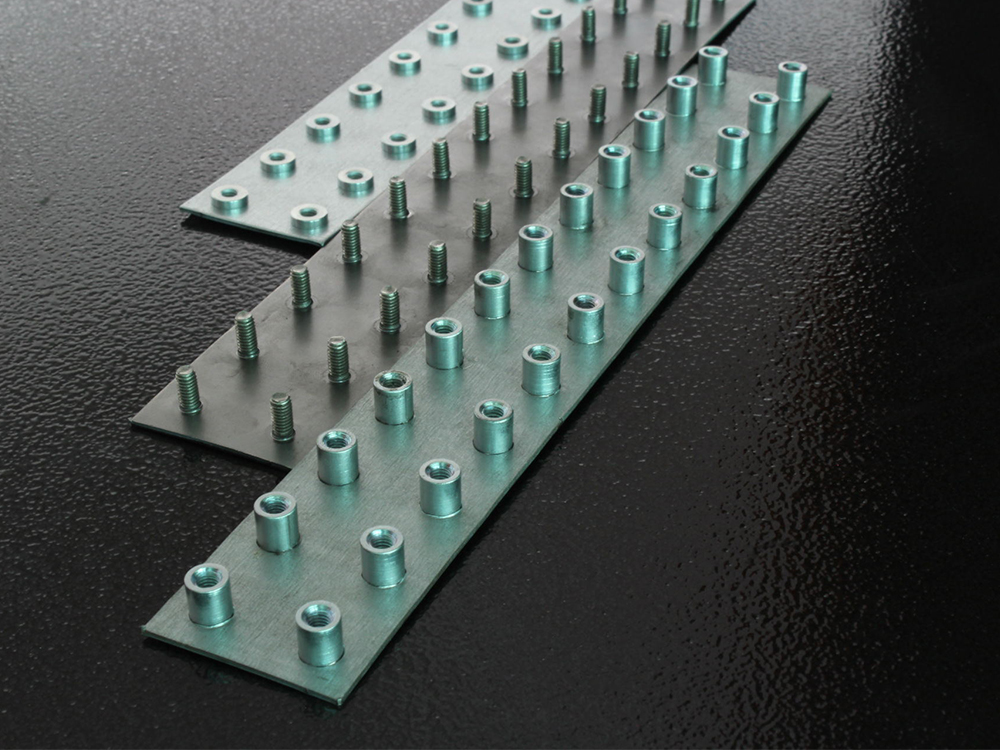

Sheet metal part means thin plate hardware, it is a kind of component manufactured by laser cut, stamp, bend, and stretch. For sheet metal component from any industry, it has a manufacturing process, and following is the basic technological process of sheet metal design and produce.

Sheet metal processing resource

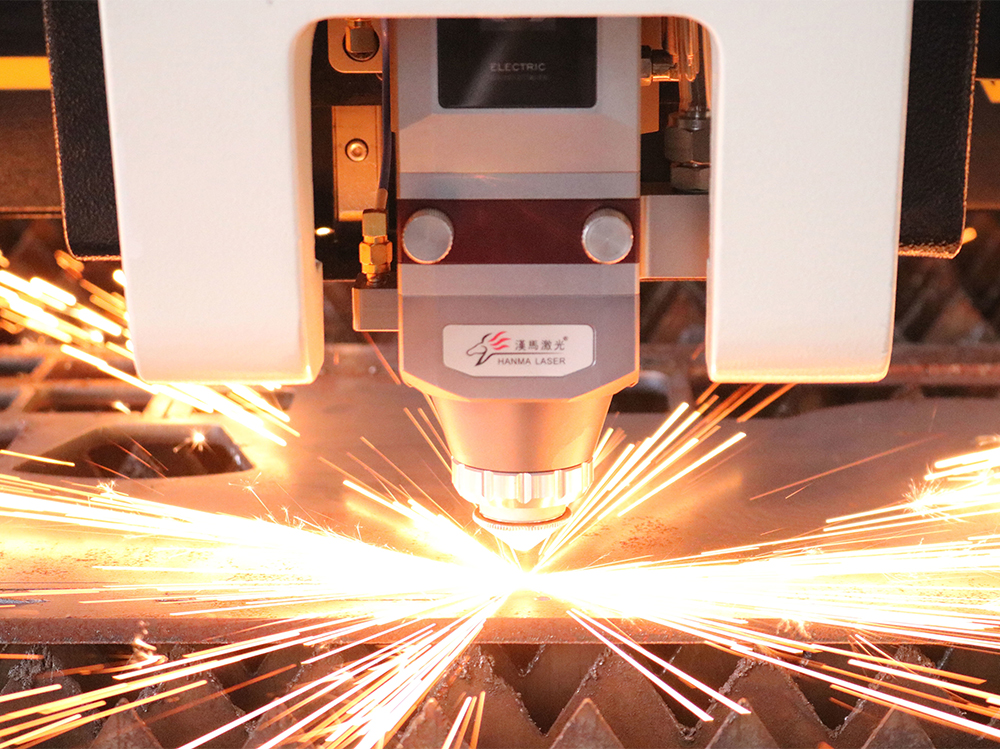

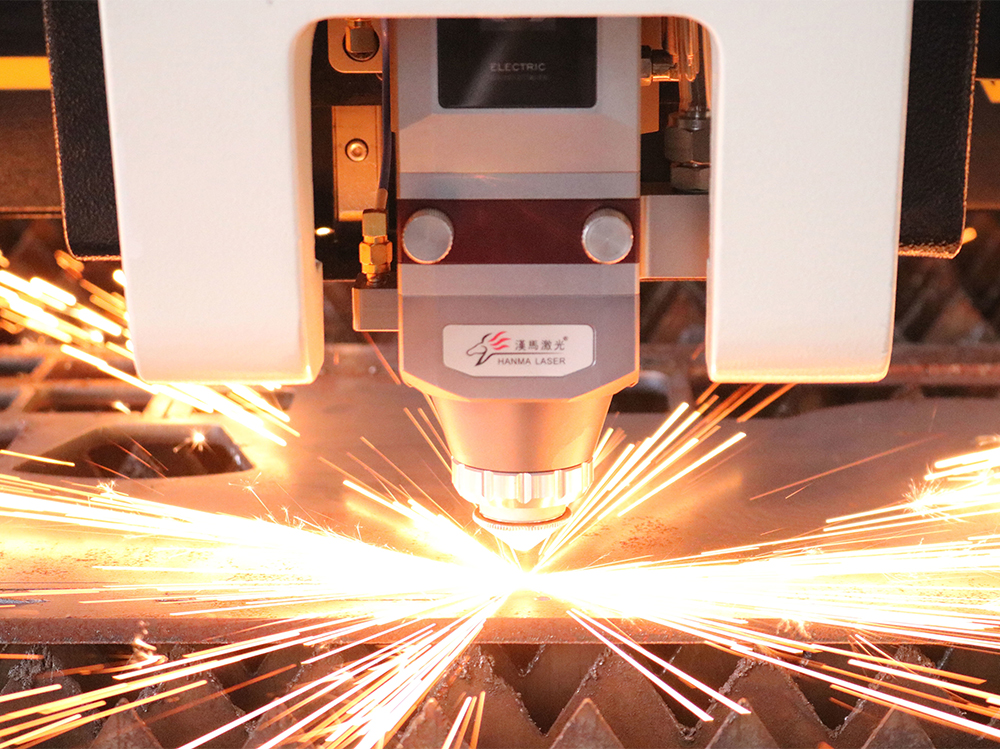

Laser cut

Bend

Sheet metal stamp

Application industry of sheet metal processing

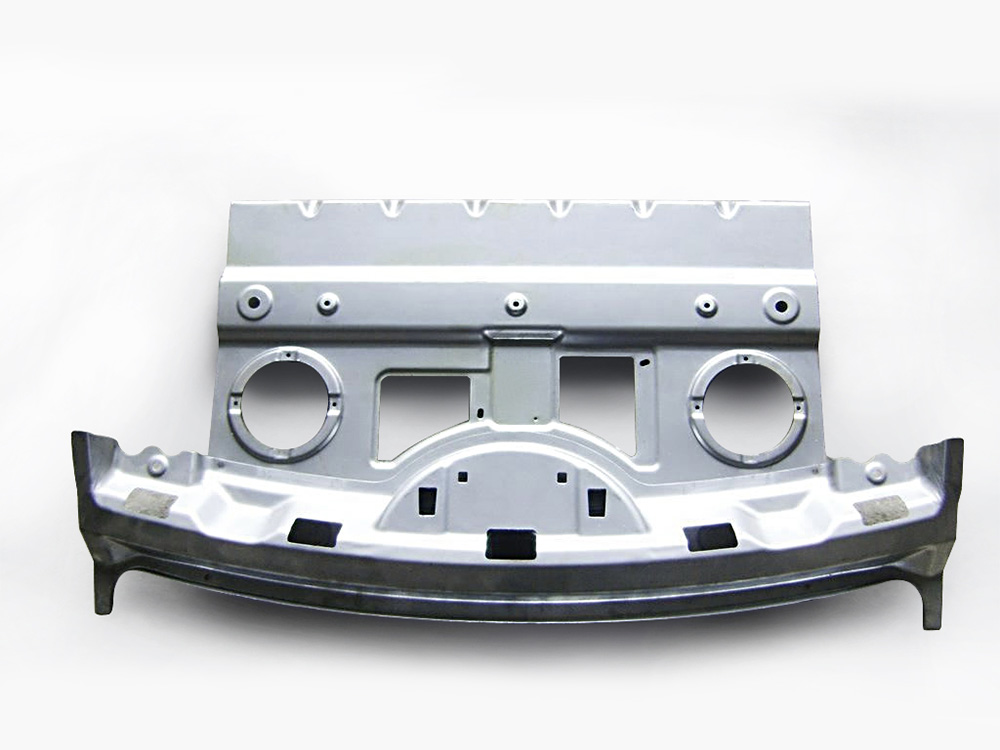

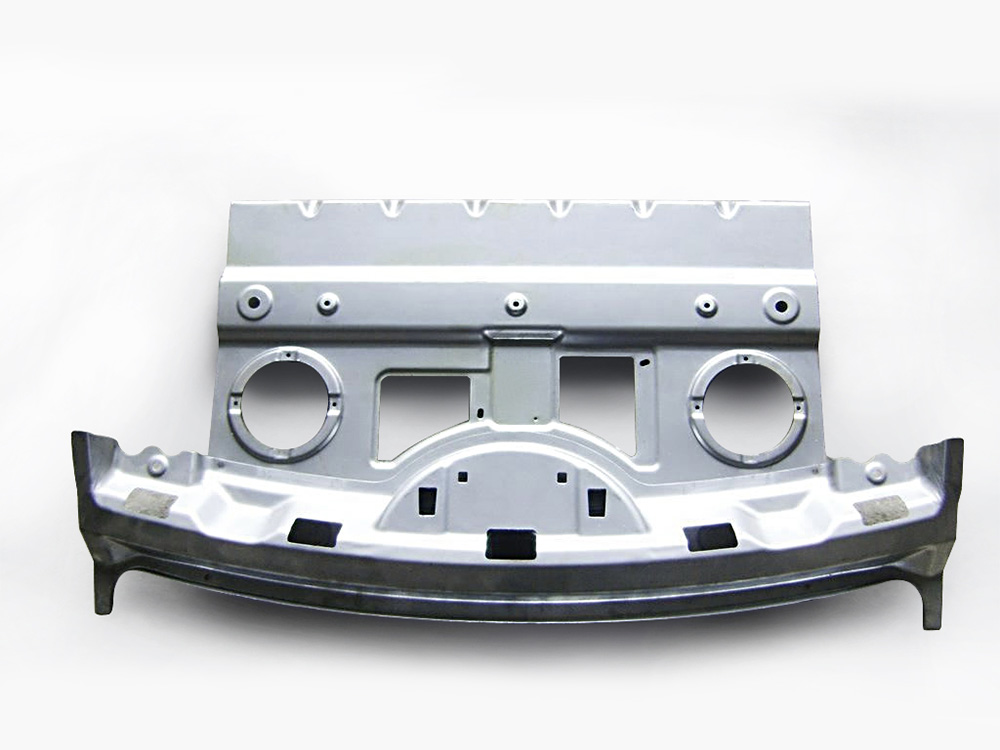

Sheet metal parts are light weight, high intensity, good conductivity, low cost and also high performance in massive production.It’s widely used in automobile, communication equipment, kitchen electrical, appliance, medical devices, ship, mechanical and office equipment industries.In GREFEE, we provide professional manufacturing service of sheet metal component, we help you get low cost products!

Automobile

Sheet metal can be used to manufacture doors, bodies, seats, links, vulnerable parts, etc

Communication equipment

Sheet metal can be used to manufacture the shell and heat dissipation part of communication equipment.

Kitchen electrical

Sheet metal can be used to make kitchen equipment shells, links, etc.

Appliance

Sheet metal can produce household appliance shell, heat sink, link parts, vulnerable parts, etc

Medical devices

Sheet metal can produce medical equipment shell, heat sink, link parts, vulnerable parts, etc

Ship

Sheet metal can produce hull, blades, power equipment parts, links, vulnerable parts, etc

Mechanics

Sheet metal can produce mechanical equipment fuselage, connectors, pressure parts, vulnerable parts, etc

Office equipment

Sheet metal can produce office equipment panels, supports, links, vulnerable parts, etc

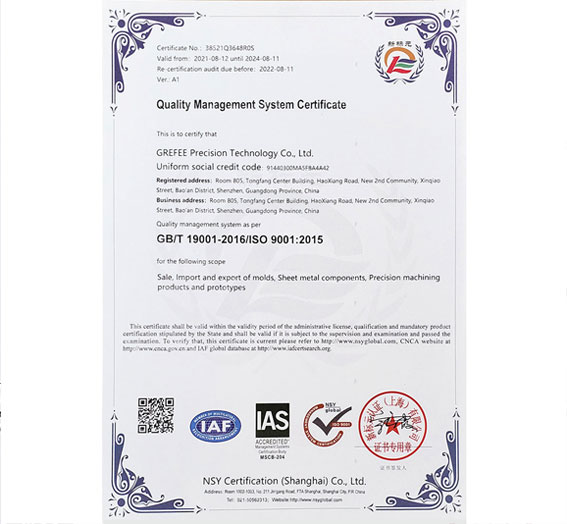

Quality assurance

GREFEE set a through management and quality control process from feedstock, manufacturing and delivery. Every process is inspected, full-scale QC report, material certification and qualification are valid for all products.

- We insist that every product should go through following inspection steps:

- All materials are inspected and recorded before manufacturing, to assure material accuracy.

- Every process has FAL inspection in manufacturing, all are affirmed and checked by engineering and quality managers.

- Products are 100% inspected before warehouse.

- Products are inspected again before delivery and attached delivery report.

- All equipments and machines are inspected, revised and identified regularly

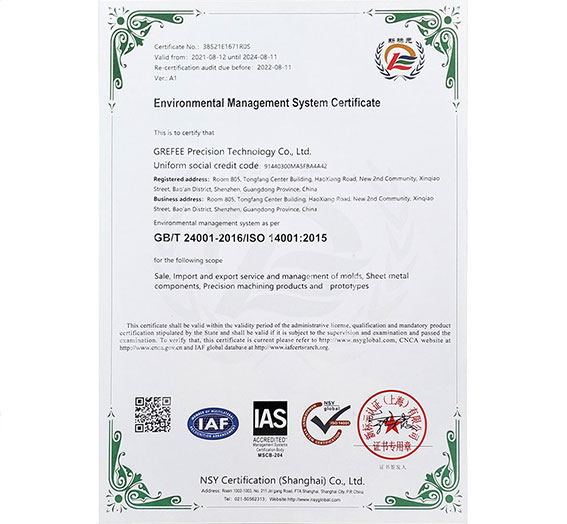

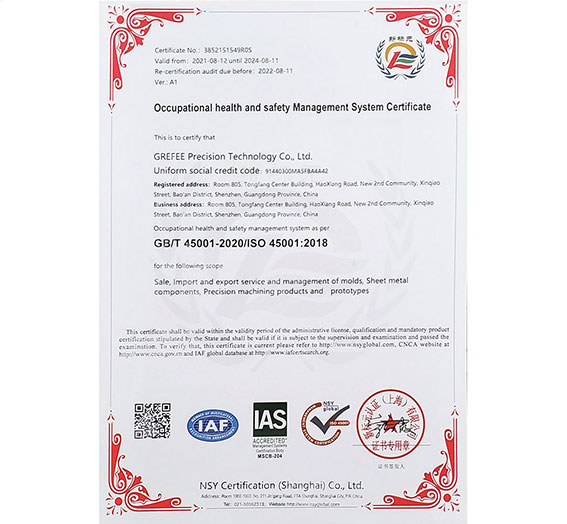

- We strictly follow ISO standard, assure product quality and lead time, and pay a return visit regularly and conduct satisfaction survey, accepting feedbacks from customers, which improves our team constantly.

Why GREFEE

- Competitive price: we value much on cost control from raw material incoming to manufacturing step.

- One-stop service: We’re not only provide sheet metal working service, but also support related complete flow service such as: CNC machining, die casting and injection moldin.

- Strict quality control: we’re ISO9001 certificated, we’ll make sure all parts are 100% qualified delivery.

- Delivery on time: urgent part made within 1 day, small batch delivered within 1 week, and large volume parts are delivered 2-5 weeks.

Common problems in sheet metal working(FAQs)

- Raw material cost: generally means the metal plate material cost in sheet metal components, it calculated based on part weight in expanded drawing, weight equals to maximum length*width*thickness*density, and material cost equals to material weight*material unit price.

- Sheet metal processing cost: it means the cost of manufacturing processing, usually it consists of machine amortization of depreciation, labor time cost and auxiliary material cost required in manufacturing processing.

- Hardware accessories cost: it means the cost of purchasing complete lockset, hinge, drag, nameplate, rivet and fastening standard accessories as product drawing required.

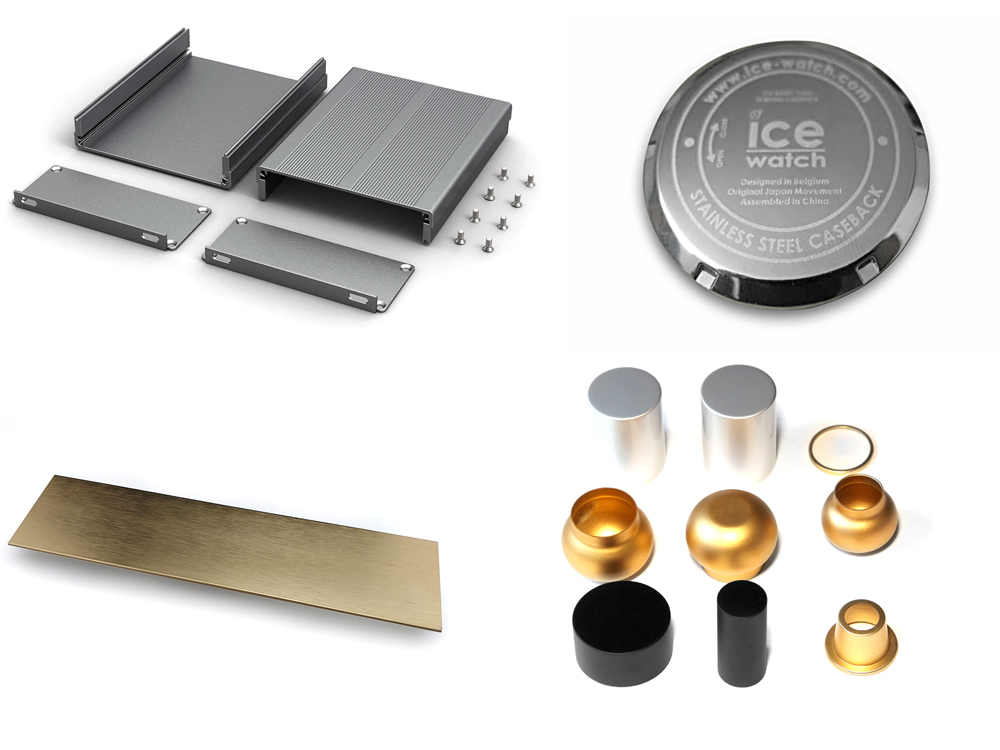

- Sheet metal finish cost: common finish in sheet metal are electroplate, anodize, painting, E-coating, brush….etc. Sheet metal finish cost is calculated by product area and weight.

- Sheet metal parts packing cost: packing material purchasing cost and labor cost according to transportation modes and package demands. Above are rough cost structure in sheet metal components, to be specific, it still needs calculating combine product size, surface requirement, precision demand and package.

- Sheet metal aluminum material: Property: Aluminum is a light metal material, with good corrosion resistance, electrical conductivity and thermal conductivity. Application: aluminum is glossy and soft, can be made to different colors and characters functionally and decorative products. Types:AL5052-H32,AL5052-H24/H34,AL5754-O,AL5754-H22,AL6061-O, AL6061-T451,AL6061-T6,AL6061-T651,AL6061-T6510 ,AL6061-T6511,AL2024-T3,AL2024-T351,AL2024-T3511,AL2024-T4,AL2014-T6,AL7075-T3,AL7075-T6,AL7075-T651,AL7075-T6511.

- Sheet metal copper material: Property: good electrical conductivity, thermal conductivity and corrosion resistance, easy plastic working, easy to electroplate and coating. Types:C1020、C1100,C2100,C2200,C2300,C2400, C2600, SF-CU.

- Sheet metal stainless steel: Property: good corrosion resistance and radiance, high intensity, with certain elasticity. Types:SUS301-H,SUS301-1/2H,SUS301-1/4H,SUS301-3/4H,SUS301-EH,SUS301-SH.

- Sheet metal spring steels: Property: spring steel can be largely transformation, elastic deformation is used for absorbing shocking or damping, and also storing energy then makes components operate. Types:1056,9255,9260,5155,5160,6150,51B60,SUP6,SSUP9,SUP9A,SUS10A,SUS11,55Si7,60Si7,55Cr3,51CrV4,58CrMnB4.

- Sheet metal Zinc material: Zinc-plating board: metallic white luster, checkered, surface not easy to rust, but may have white rust spots by corrosion. It's suitable for products made for refrigeration, air conditioner, electrical machine, and roof structure. Types: Z60,Z80,Z90,Z100,Z120,Z180,Z250,Z275 Z350.

- Cold-rolled sheet: iron grey luster, surface easy to scratch and rust, need pay attention to protect and quick turn order in processing. It’s suitable for products made with electroplate(Choi zinc, white Zinc plating, Nickel plating, Tin plating…..), stoving vamish painting, powder coating….etc. Types:GB700,Q195,Q215,08AL,Z,S,P/08AL,ZF,HF,F/DX1,DX2,DX3,SEHC

- Hot-rolled plate: black grey luster, surface not easy to scratch, but easy to rust, needs pay attention to remove in processing. Types:JIS G3101,JIS G3131,DLN 1614(EN10111),DLN 17100(EN10025),JIS G3106,NSC,DLN 17200,,DLN 17102,JIS G3132,JIS G3113.

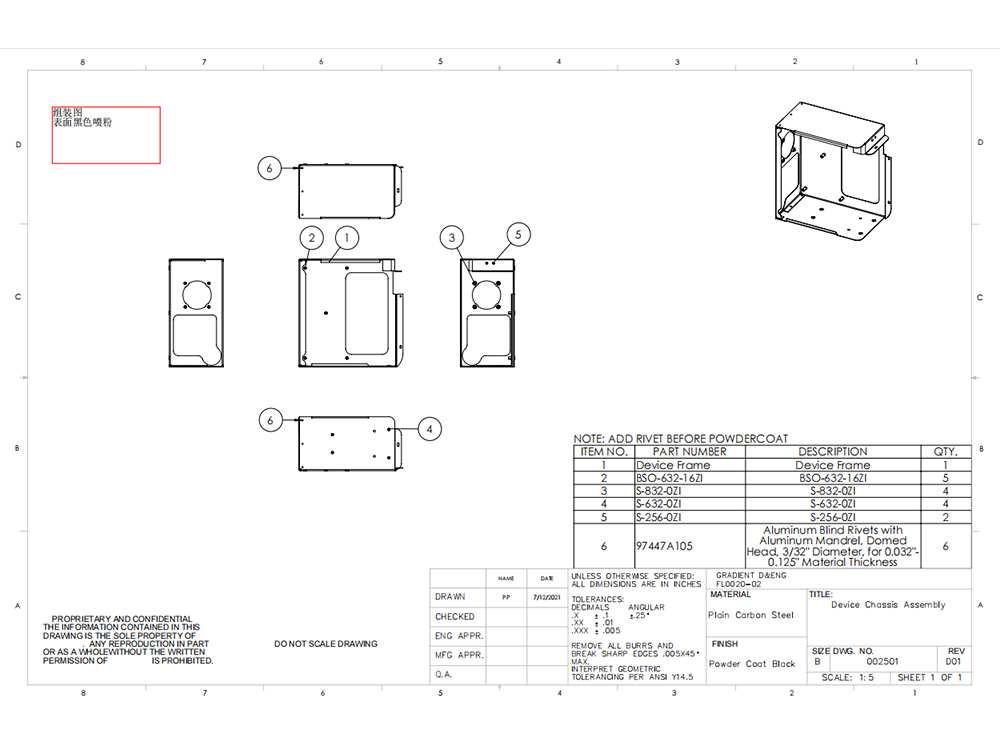

Customer cases in sheet metal processing