causes analysis and improving methods of underfeeding issue in die casting products

Posted on : Apr11, 2022 By GREFEE

What is underfeeding in die casting?

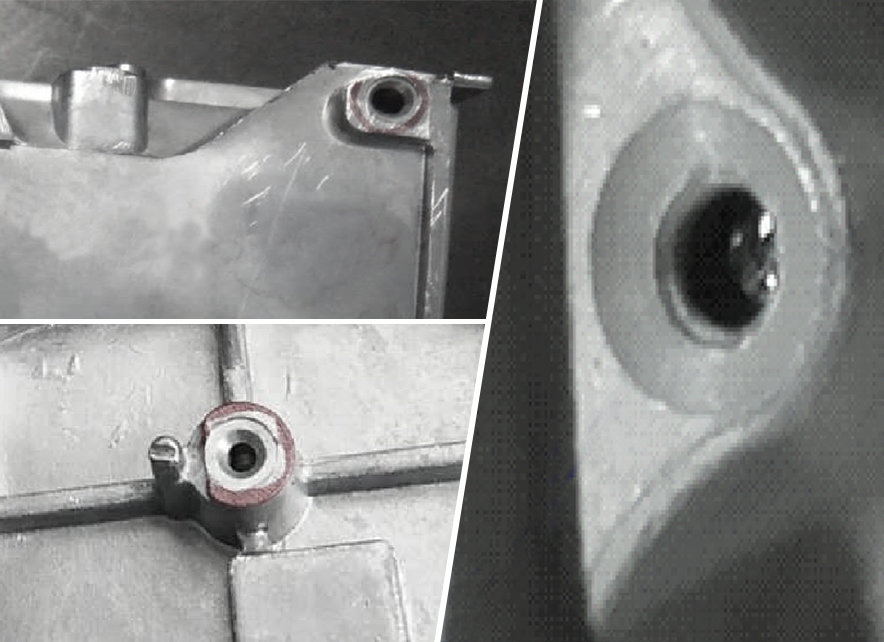

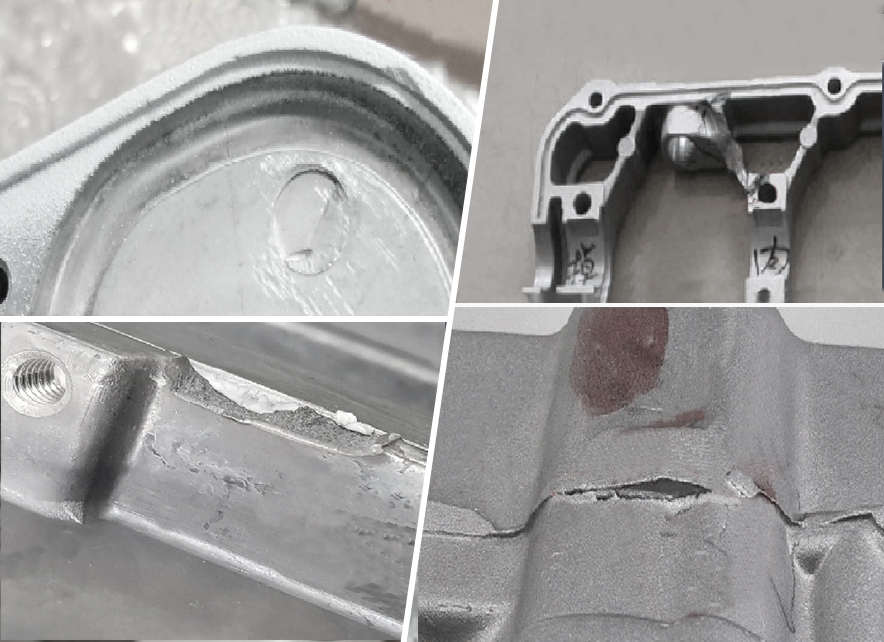

The surface of the die casting parts sinks due to the mold damages, collisions, and other reasons. The irregular shapes and changeable locations can be improved by welding.

causes of underfeeding in die casting process

- Mold manufacturing reasons, overfeeding in the local cavity or wrong sizes

- The mold is invalid and there is checking and heavy type cavities protrude

- The mold cavity surface is mechanical damaged, like collision, extrusion and other factors which lead to protrusion in local areas

- The connection areas of side pull blocks and core have wear, which lead to the slide moving forward.

- Caused when removing the pouring system, like the direction of drop gate, the method is incorrect, etc. the in-gate is too thick.

- When operating, ballast, collision or throwing will cause sharp corners and edges, or surface underfeeding in casting parts.

- There is adhesive in the local areas of mold cavity.

- There is edge collapse and machined surface indentation in operation process.

How to improve the die casting underfeeding issues?

- Size inspection and mold cavity fixation.

- underfeeding can be found through the surface quality inspection. Repairs the mold or re-produces the mold replicas.

- underfeeding can be found through the surface quality inspection. Repairs the mold cavity surface.

- Size inspection. Repair the

- Properly designing the thickness of in-gate. When removing the pouring system, it is better to use punching dies.

- Strictly follow the guidelines of products transportation and the instructions of each procedure. Be aware of the protection of casting parts.

- Inspecting and cleaning molds in time.

- selects correct coefficient in operation, like rotation velocity, feeding amounts, etc. Besides, the direction of feeding should be selected correctly. It should be careful in clamp process.

key inspection areas of die casting parts: Gate and slag ladle position

How does underfeeding affect the products?

The appearance of products, especially the appearance of paint baking parts

how to know whether there is underfeeding or not?

The underfeeding measurement of die casting parts is mainly processed visually or by calipers

- Underfeeding is not allowed in the appearance or bake paint surfaces.

- Non-appearance surface ≤0.1mm

- When there are requirements for products, follow the requirements

- Underfeeding can be repaired by welding but with high cost.

improves the quality of die casting parts

- Underfeeding is most likely caused by improper practices, so good suppliers are extremely important.GREFEE has detailed and professional rules for each operators for obtaining the flawless products.

If you are looking for professional die casting suppliers, contact GREFEE! Our one-stop service spanning from small volume production to mass production.

Try GREFEE now,for free

We keep your uploaded files confidential and secure.