Causes analysis and improvement methods of undercasting die-casting products

Posted on : March 22, 2022 By GREFEE

To learn more problems and preventions of die casting, click to check it out.

What is die casting undercasting?

In die casting, the place that is filled incompletely during the process or places that are not close enough are called undercasting, also named short run. The existence of these defects will affect the interior and exterior quality of the casting.

Causes analysis and improving methods of undercasting die-casting products

Causes:

poor alloy floweriness:

(1)high air content in metal liquid, oxidization heavly, causing flowliness

(2)the alloy pouring temp and mold temp are low

(3)inner gate speed is too low

(4)nitrogen gas pressure in accumulator is insufficient

(5)low filling degree in pressure chamber and low pressure ratio

(6)imporper design, such as too thin casting wall thickness or a great dispraity in wall thickness

Improper pouring system:

(1)gate position, diversion mode or improper selection of the number of in-gate strands

(2)In-gate cross area is too large

(3)Poor venting conditons

(4 )poor venting

(5)too much mold release agent, doesn’t dry and burn out completely

(6)mold temp is too high, air pressure inside the cavity is too high, uneasy to exhaust

How to improve die casting undercasting?

1. Improve the floweriness of alloys

(1)poor interior quality of product, too many bubbles on the surface-refining alloy liquid, try to exhaust the air and non-metal impurities

(2)Accompanied by cold shut and flow mark – increase the alloy during temp and mold temp appropriately

(3)small sinks on product surface, cold shut around the undercasting- increase the shot speed appropriately

(4)the pressure gauge has cushion and value does not meet the die casting standards, the casting presents insufficient compressing – supply nitrogen to improve the effective pressure

(5)cold metal marks on die casing surface, there is insufficient compressing sings – adjust the diameter of pressure chamber, increases the shot pressure ration, applies quantitative pouring

(6)obvious cold shut and insufficient compressing sings around the thin wall thickness undercasting – improves the structure of casting, adjusts wall thickness appropriately, in addition, can open auxiliary gate.

2. Improving poring system

(1)Cold shut at the front end of undercasting and insufficient fusing signs – select gate position, diversion methods, and gate strands according to the filling simulation or actual molds

(2)Often appears in-gate sticking problems – enlarge the in-gate cross area or increase injection speed.

3. Improving venting conditions

(1)The color of the area around undercasting turning black, accompanied by impurities and air bubbles etc – adds overflow groove and venting channels, uses ejector rod gap or core gap to help with the venting in deep cavity.

(2)Gloomy surface color, heavy flow marks – applying mold release agent thin and uniform, clamping the mold after dry and burn out.

(3)Often appears mold sticking problems, server strains, bubbles on the surface, decreases the mold temp to the standardized range of process.

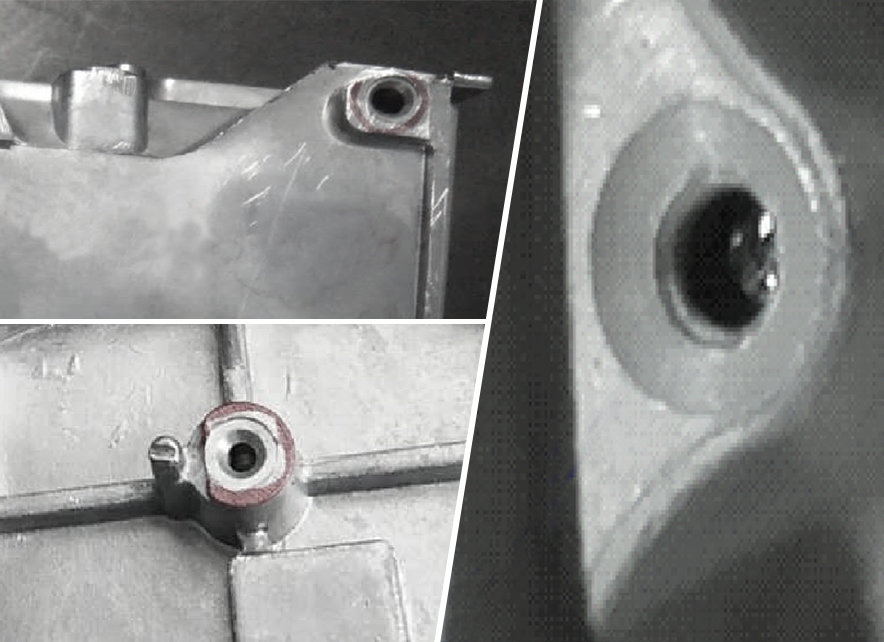

Key inspection areas for die casting components:

Generally, the undercasting will be on the pillars, heat sinks, sealing ribs, and extension part of product body.

How undercasting influences the products?

Undercasting will cause unqualified airtightness and water resistance; it will further affect the CNC machining of die casting machines to the integrity of tapping; it will also affect the surface treatment of products, such as baking finish quality, blasting, sandblasting or electroplating, etc.

How to judge whether an undercasting die casted parts is qualified or not?

Generally, it will use eyes to measure. If it is a tiny part, we can use a microscope, and do a dimension measurement on the defects caused by the undercasting to evaluate whether the product is qualified or not:

The underfeed problem which caused by any undercasting areas on die casting parts are unqualified.

Undercasting on product surface is unqualified.

Non-functional parts and cavity should not exceed 1/100 of the length of the contour.

If customers have standards, follow the customers’ standards

Improves the quality of your castings

GREFEE believes that finding out whether there are any undercasting issues in the stage of design and CAE analysis or not is essential. In addition to other factors, like the influence of die casting technology and mold. Eliminates the risks before initiating the project.

If you also got undercasting problems, Contact GREFEE for free technical support.

Try GREFEE now,for free

We keep your uploaded files confidential and secure.