causes analysis and improvement methods of flow marks of die casting products

Posted on : March 24, 2022 By GREFEE

To learn more problems and preventions of die casting, click to check it out.

What is the flow mark of die casting products?

First, the liquid metal flows into the cavity and forms a sheer and incomplete metal layer. The flow mark is generated by the later liquid metal.

The casting surface has patterns in the same direction as liquid metal. There are evident patterns without directions different from the metal by color and with no developing tendency.

Causes:

1.The in-gate cross area is too small, and the position is incorrect, which causes the liquid metal to fill the cavity inconsistently or generates the marks due to the overfill.

2.The mold temperature is too low and uneven; the condition that the aluminum alloy mold temp is lower than 180℃ are all likely to have this type of defect.

3.The filling speed is too fast. The Splashes are produced by the small in-gate cross area and improper position.

4.Insufficient pressure on the liquid metal.

5.Patterns: uses too much mold-release agent.

how to improve the flow mark issues in die casting?

1. adjusts the in-gate cross area, position, or filling direction to achieve consistent filling.

2. measure the mold temperature by the mold thermometer. adjusts the mold temperature to the required range.

3. Product surface, the liquid metal stream around the ingate will have an ultra brightening area. Adjusts the filling speed to change the liquid metal flow state in filling.

4. The product surface turning black, there is mold release agent residue in the local area. Alters the concentration of the mold release agent. The mold release agent should be thin and uniform.

5.The opposite side of the casting surface in-gate is likely to be not compacted and gloomy surface. Adjusts the injection pressure properly.

Key inspection areas for flow marks in die casting

Generally, the flow marks are around the gate or gate accessories or the junction of several strands of liquid metal.

How does flow mark affect the die casting parts?

The flow mark mainly affects the airtightness and the appearance of products after cleaning.

How to evaluate whether a die casting part with flow marks qualified or not?

Mainly by checking by visual or through grinding the products.

1. The flow mark area should not exceed 5% gross area.

2. If there are requirements, follow the products’ requirements.

3. Flow marks indicates there might have sandhogs inside.

4. Removes by polishing or blasting.

MORE BOLG

Insert mold in injection mold service

What are advantages and disadvantages of Zinc alloy and Aluminum alloy?

Inspection standards for injection molded partappearance

How to judge the quality of your plastic products?

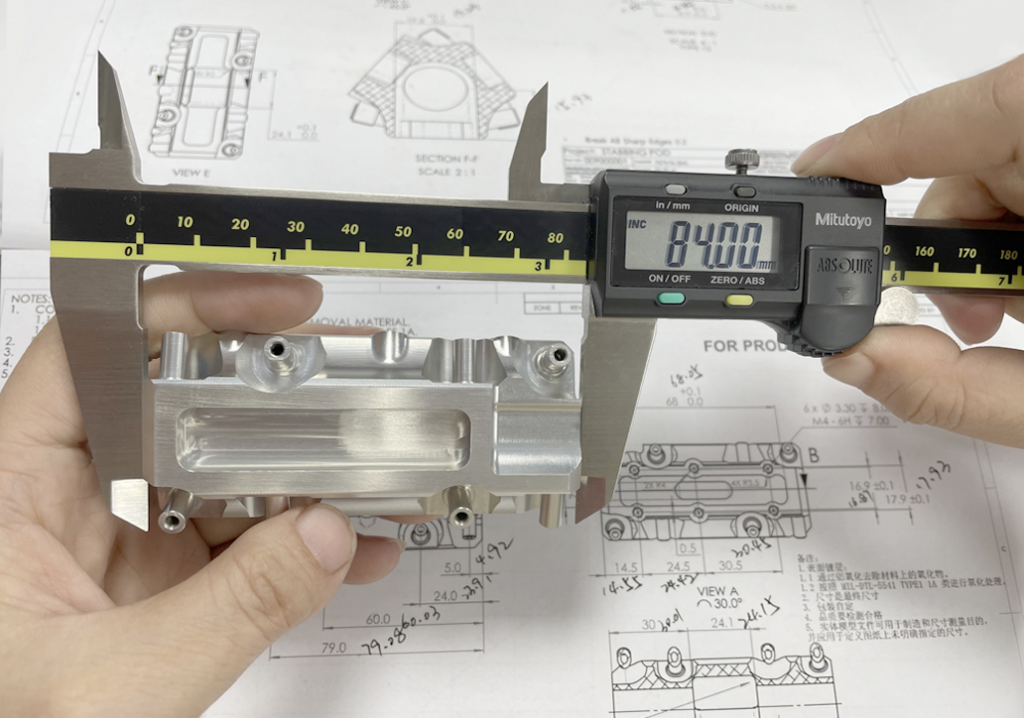

Inspection standards for CNC machining

To ensure that your products are 100% qualified

Categories

Try GREFEE now,for free

We keep your uploaded files confidential and secure.