Application of laser welding and cutting in sheet metal industry

Posted on : June 2, 2022 By GREFEE

The laser beam is easy to transmit. Its temporal and spatial characteristics can be controlled respectively. A very small sot can be obtained after focusing. The laser beam has quite a high power density, can melt and gasify any material, and carry out precision and rapid machining in local areas. In the machining process, the input heat of the workpiece, heat-affected zone, and thermal deformation is small. Due to its high processing efficiency, it is easy to achieve automation. Laser technology is a comprehensive high technology, including optics, mechanics, electronics, etc. It is still under continual development and improvement. The contemporary laser and laser processing technology and equipment have matured after years of research. Besides, various new laser processing technology and equipment have been fully developed, forming a series of laser processing technology. In addition, different new laser processing technologies are still emerging.laser welding aluminum and aluminum alloy cutting are also the projects with the most laser processing lines.GREFEE provides laser cutting services and laser welding services.CONTACT US

From the perspective of practical application promotion in the international scope. Laser machining is mainly used in cutting, welding, surface treatment, marking, and punching. 65% laser welding Two-dimensional and three-dimensional accounts for 65% of laser applications. Laser welding accounts for about 20% of laser drilling. Marking accounts for less than 10%. Laser surface treatment includes laser transformation hardening, laser cladding, laser surface alloying, and laser surface melting only accounts for just 5%. From the development and application of domestic laser machining technology, more and more customers have learned the excellent properties of laser machining, such as high flexibility and efficiency. Currently, laser technology has been popularized in many industries, including aerospace, automotive, switching, gear, railway locomotive manufacturing, and metal material processing industries.

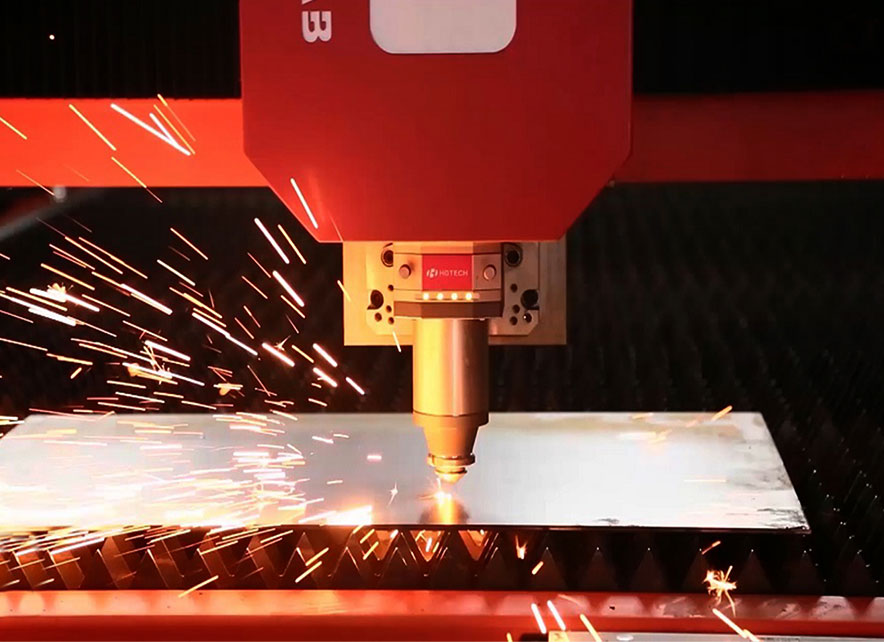

characteristics and applications of the laser cutting

Laser cutting is the laser machining technology that has been widely used worldwide in many fields, such as automobile manufacturing and machine tool manufacturers using laser cutting to process sheet metal parts. With the quality improvement of the high power laser beam, its application range has been widened, involving all metallic and non-metallic materials. The laser beam is also applicable for material with high stiffness, high brittleness, and high melting point to process complex shapes of three-dimensional part cutting, which is the advantage of laser cutting.

Major advantages of laser cutting

1.Laser cutting is a non-contact and optical thermal processing, also being called the “multipurpose instrument that damages”. It can process any mode of tight nesting or nesting, making the material fully used. Due to the non-contact machining, the machined parts have nothing changed.

2.One of the advantages of laser cutting is its high efficiency. Take the 1mm thick aluminum alloy plate as an example. The cutting speed can reach 40m/min. High efficiency makes the cost for the single piece lower than the traditional cost or reduces geometrically.

3.Laser cutting does not need tools and molds. It works under the control of the computers, which can achieve the flexible machining of the plate and shell parts with arbitrary shapes in two and three dimensions, especially for the R&D stage and multi-variety and low volume sheet metal processing. It effectively reduces the cost of mold design and manufacturing cost. Besides, it largely shortens the production cycle.

4. The kerf width of laser cutting is extremely small, from 0.15 – 0.4mm. The cutting is smooth and without burrs. It can process the gear products straight away for transmission with certain accuracy.

characteristics and appplications of laser welding

Laser welding is a high-speed and non-contact weld mode with minor deformation, suiting for massive and consistent online processing. With the development of laser equipment and processing technology, the laser welding capacity is increasing, too. Currently, using the 4kW laser to carry out the 1mm plates, the welding speed is as high as 20m/min. The large plate of the car bottom in the automotive industry uses laser welding for this work. Laser welding is one of the most important applications of lf2700ha technology in laser material processing

laser welding advantages

Comparing with other welding technologies, the major advantages of the laser welding machine are:

1.laser wedling is fast. The weld depth and width is large (could be 5-10), little deformation.

2.It is well-particularly suitable for processing precision parts, box parts, and weldments with sealing requirements. After the laser beam is collected, a small spot can be obtained. It also can be positioned precisely, suiting for mass production automotive production. It increases the production efficiency effectively in a small heat-affected zone. The welding point is non-polluted, which enhances its welding ability.

3. The mechanical performance of the laser welding machine is good. The mechanical performance of the general welding is higher than the base metal.

4. There is no need to block or vacuum environment in welding, which is of great sifnificance for the industrialized scale production.

5.Through the laser wire feeding welding, laser powder feeding welding, and new technologies, the laser industrial application is achieved, and the application fields expand.

6. For the weldable and hard-to-reach areas, we can carry out non-contact long-distance welding. Especially the YAG laser processing technology in recent years, the involvement of the optical fiber transmission technology has effectively increased its extension and application range.

7.overall, the advantages of laser welding: high strength, long service life, high welding speed and efficiency, simple lap joint process, low scrapping rate, low positioning accuracy, suited for industrial production, such as military enterprises, food industry, chemical industry, and petrochemical industry.

Typical application

1. Application of laser welding technology in heat exchanger

laser welding is popularized in the heat exchanger industry due to its reliability and high efficiency. The thermal exchanger products generally have many welds, complex structures, and poor working conditions, limiting the development of the products. The successful application of laser welding in this industry enhances the competitiveness of products and lowers the cost and production cycle. Currently, this kind of product is widely used in China.

2. Application of laser welding in switch industry

The switch cabinet is the leading product in the high-voltage switch products, requiring a reliable sealing in the natural for more than 30 years. The traditional wedding method has many issues like the deformation of the box after machining, poor air tightness, low processing efficiency, and high-cost issues. The modular design of the three-dimensional laser processing machine tool can realize the laser welding task of a switch box with a curved surface

The special welding powder control, weld track system, programmable protective gas system, and laser wire feeding & welding device make the welding quality meet the requirements of the mass industrialization fully. The adoption of 3D programming software enhances efficiency and lowers faulty rates. Now, laser processing devices are used to cut and weld in many high-voltage switch manufacturers.

3.Application of laser welding in gear machining

The laser welding gear technology has changed the traditional design and manufacturing concepts completely. It provides a more economical and tighter structure for the gearbox parts machining. The first thing that needs to do for using this technology is to process the ring-shaped long gear ring and cut it into several gear rings, then weld them to the drive shaft according to the needs of the gearbox.

Laser processing technology has been widely used in different fields. With the deeper R&D of the laser machining technology, devices, and technical research, it will reach a wider application range.

Try GREFEE now,for free

We keep your uploaded files confidential and secure.