Common metal forming process

Posted on : July 4 , 2022 By GREFEE

One thing that manufacturers really concern is the metal material forming method, which is a key part in the parts design, and also an essential factor in material processing. Below are few current used forming methods.

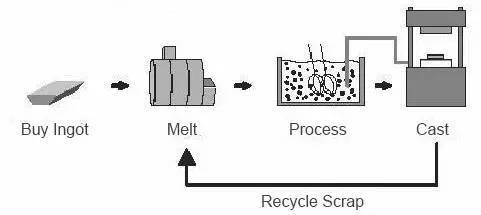

Casting

Liquid metal is poured into the casted mold cavity that is similar to the shape and size of the parts. After it is solidified, we can obtain the blanks and components, which is often called the liquid metal forming or casting.

Process procedures: liquid metal — filling and forming — solidifying and contracting — casting

Characteristics of process

1. Produce parts in any complex shape, especially the ones inside the inner cavity.

2. Strong adaptability, which is not limited to any alloy type. The size of the castings are not limited, too.

3. Wide sources of materials, remelting of waste products is allowed and low equipment investment.

4. High scrapping waster, low surface quality and working conditions.

Die Casting Classification

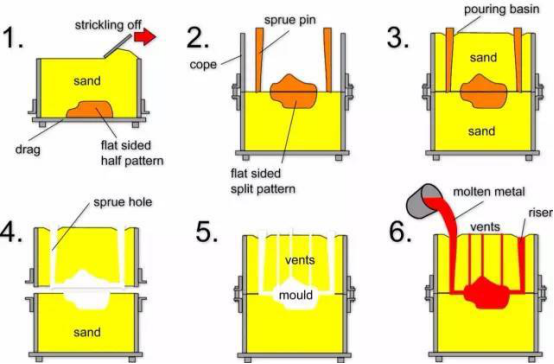

1.sand casting

Sand casting: castings obtained from the sand models, which is applicable to steel, iron, and most nonferrous alloy castings.

Process procedures:

Technique characteristic:

(1). Applicable to banks with complex shapes, especially with complex inner cavities.

(2). Wide adaptability, low cost.

(3). For materials with poor plasticity, such as casted iron, sand casting is the only means for producing the components and blanks.

Applications: Automobile engine cylinder block, cylinder head, crankshaft and other castings

2.investment casting

investment casting: investment casting way in which a pattern is made of fusible materials, several layers of refractory materials are coated on the surface of the pater to make a mold shell, and then the pattern is released out the shell to get a mold without parting surface, which can be filled with sand after high-temperature roasting. It is often called “dewax casting”.

Advantages:

- High dimension accuracy and geometrical accuracy

- High surface roughness

- Capable of making castings with complex appearance without the limitations on the alloy types.

Disadvantages: complex procedures, high cost

Application: small parts with complex shapes, high accuracy, and high processing difficulties, such as blades of the turbo auto.

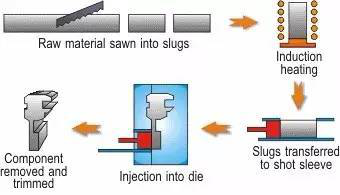

3.die casting

Die casting: die casting utilizes the high pressure to inject the liquid metal into a high premise metal model cavity, and the liquid metal solidified under the action of pressure to form the part.

Advantages:

- The liquid metals bear high pressure in die casting with high flow speed.

- High products quality with stable size and good interchangeability.

- High production efficiency. Multiple use of die casting molds.

- Suitable for mass production with high profit.

Disadvantages:

(1). A high possibility of the formation of porosity casting.

(2). Low plasticity which is not suitable for working under the impact load and vibrations.

(3). High melting point alloy die casting with short service life, affecting the expansion of the production.

Application: Die castings were first used in the automobile industry and instrument industry, and then gradually proliferated to various industries, such as agricultural machinery, machine tool industry, electronic industry, national defense industry, computers, medical devices, clocks, cameras and daily hardware.

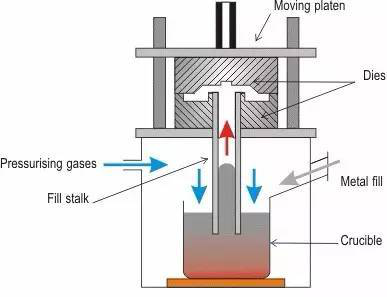

4.low pressure casting

Low pressure casting: the liquid metal works under a low pressure (0.02~0.06MPa) to fill the cast mold and form the castings under the pressure in the way to form the grains.

Process procedures:

Technology characteristic:

(1). Adjustable pressure and speed in pouring, so suiting various casting modes (such as metal, sand, etc), alloys and casting in different sizes.

(2). Bottom injection mold filling is adopted without splashing, which can avoid the gas trapping and the flushing on the walls and cavity cores, increasing the pass rate of the castings.

(3). The casting crystallizes under pressure, with compact structure, clear outline, smooth surface and high mechanical properties, which is particularly beneficial to the casting of large and thin-walled parts.

(4). The feeding riser is omitted, and the metal utilization rate is increased to 90 ~ 98%.

(5). Low labor intensity, good working conditions, simple equipment, very likely to achieve mechanization and automation.

Application: mainly include traditional products (cylinder head, wheel hub, cylinder frame, etc.).

5.centrifugal casting

centrifugal casting: a method works by pouring the liquid metal into the rotating casted models, filling the mold under the centrifugal force.

Process procedures:

Advantages:

(1). extremely low consumption in the gating system and riser system to improve the process yield;

(2). Without using the core in the production of hollow castings, the metal filling ability can be significantly improved in the production of long tubular castings;

(3). High density. Less holes and slag wells. High mechanical property.

(4). suitable for manufacturing cylinder and sleeve composite metal castings.

Disadvantages:

(1). limitations exist in producing special-shaped castings;

(2). The inner hole diameter of the casting is inaccurate, rough inner hole surface, poor quality, large machining allowance.

(3). Castings are likely to be specific gravity segregated.

Application:

Centrifugal casting was first used to produce cast pipes, which now has been involved into many production lines, like the metallurgy, mining, transportation, drainage and irrigation machinery, aviation, national defense, automobile and other industries to produce steel, iron and non-ferrous carbon alloy castings. Among these, the centrifugal cast iron pipes, cylinder liners and shaft sleeves of internal combustion engines are the most common.

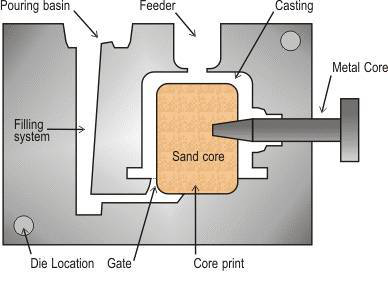

6.gravity die casting

gravity die casting: it refers to a method in which the liquid metal filling the metal mold under the gravity and then solidifying to obtain the castings.

Process procedure:

Advantages:

(1). The thermal conductivity and thermal capacity of metal mold are high. The cooling efficiency is high. The casting structure is compact, and the mechanical properties are about 15% higher than those of sand mold castings.

(2). Castings with high dimensional accuracy and low surface roughness can be obtained with good quality stability.

(3). As sand cores are not used or rarely used to prevent the environment from being polluted by the dust and harmful gas are reduced, and labor intensity is reduced.

Disadvantages:

(1). The metal mold itself has no air permeability, so certain measures must be taken to export the air in the mold cavity and the gas produced by the sand core.

(2). The metal mold is non yielding, and the casting is likely to have cracks in the solidification;

(3). Long manufacturing cycle of metal mold with high cost. Therefore, only in mass production can it show a good economic effect.

Application:

Metal mold casting is not only suitable for large volume production of aluminum alloy, magnesium alloy and other non-ferrous alloy castings with complex shapes, but also suitable for production of iron and steel metal castings, ingots and so on.

7.vacuum die casting

vacuum die casting: It is an advanced die-casting method works through eliminating or significantly reducing the pores and dissolved gases in the die-casting parts by releasing the gas in the die-casting cavity during the die-casting process to improve the mechanical properties and surface quality of the die-casting parts.

Process procedures:

Advantages:

(1). Eliminate or reduce the gas holes inside the castings to improve the mechanical property and surface quality, and also enhance its plating performance.

(2). Reduce the cavity backpressure by using alloys with low specific pressure and poor casting performance, as well as the small machines to cast larger castings;

(3). The filling conditions are improved. It is applicable to castings with thin walls.

Disadvantages:

(1). Sealing structure of mold is complex. The manufacturing and installation are difficult and thus the cost is lifted.

(2). Inappropriate vacuum die casting method will lead to poor effect.

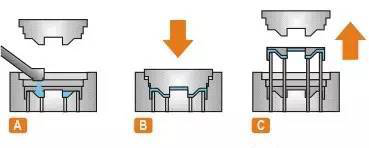

8.squeezing die casting

squeezing die casting: it is a method in which the fluid metal or semi-fluid metal solidifying under the high pressure and flow forming to obtain the parts and blanks with a series of advantages of high utility rate of liquid metal, simple operations, stable quality and other advantages. Besides, it also cost is an energy saving metal forming technology with potential application future.

Process procedure:

Direct squeeze casting: coating, alloy casting, mold closing, pressurization, pressure maintaining, pressure relief, mold splitting, blank demoulding and resetting

Indirect squeeze casting: coating spraying, mold closing, feeding, mold filling, pressurization, pressure maintaining, pressure relief, mold splitting, blank demoulding and resetting.

Characteristics of technique:

(1). Eliminate air holes, shrinkages, loosen and other defects.

(2). Low surface roughness and high dimension accuracy.

(3). Avoid the casting cracking occurrence.

(4). Is easy to achieve the mechanization and automation.

Applications: suitable to produce different types of alloys, such as aluminum alloy, zinc alloy, copper alloy, nodular cast iron, etc.

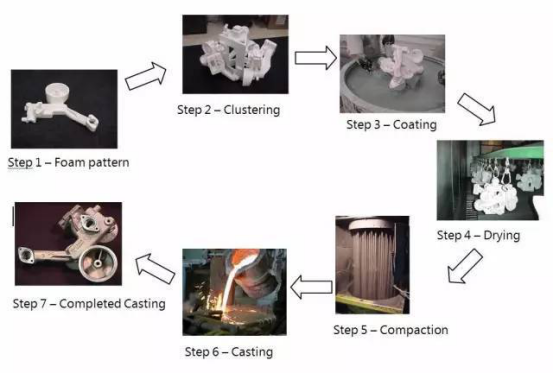

9.Lost foam casting

Lost form casting, also named full mold casting: which combines the paraffin wax or foam models similar to the size and shape of castings into model clusters, brushes with fire-resistant coating and dries them. After that, burying them in dry quartz sand for vibration molding before pouring them under negative pressure to vaporizes the model. The liquid metal occupies the model position, and forms castings after solidification and cooling.

Process flow: pre foaming → foaming molding → coating dipping → drying → modeling → pouring → sand falling → cleaning.

Characteristic of technique:

(1). High accuracy without the sand core, and reduce the processing time.

(2). No parting surface. Flexible design with high flexibility.

(3). Non pollution production.

(4). Lowers the investment and production cost.

Application: It is suitable for producing high premise castings with complex structure and various alloys with different sizes. It is not limited to the production volume, such as the cast iron engine box, high manganese steel elbow, etc

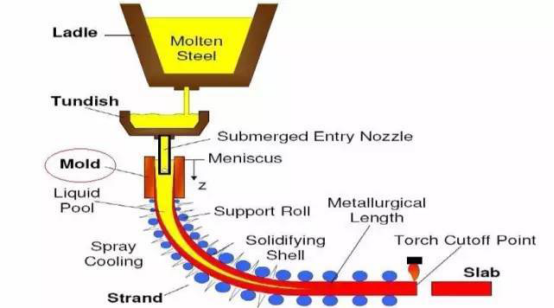

10.continual casting

Continual casting is an advanced casting methods which works by continual pouring the molten metal into a special metal mold, called the crystallizer, to solidify the casting, then pull out the part from the another end of the crystallizer to obtain castings of any length or specific length.

Process procedure:

Characteristic of technique:

(1). Since the metal is cooled immediately with dense grains and uniform structure, its mechanical performance is great.

(2). Metal saving increases the yield.

(3). Simply the procedure to omit procedures like the shaping and other steps, so the labor intensity is significantly reduced and the required production area is also reduced largely.

(4). The continual casting production is helpful in achieving the mechanizing and automation. Consequently, the production efficiency is increased.

Application:

The continual casting is applicable to produce long castings with the same section shape, such as ingots, slabs, bar billets, tubes, etc.

Plastic forming

Plastic forming utilizes the plasticity of the material. It is a process which works by producing the parts with less cutting work or non cutting at all under the external forces from the tools and molds. It has a wide variety, including the forging, rolling, extrusion, drawing, stamping, etc.

1. Forging

Forging is a process method which works by placing the pressure on the metal blank with the forging mechanics to make the plasticity deformation to obtain forging parts with a certain mechanical performance, certain shapes and sizes.

According to the forming mechanism, forging can be divided into free forging, die forging, rolling ring and special forging.

Free forging: it is typically a processing method that uses simple tools to hammer metal ingots or blocks into the required shape and size on hammer forging or hydraulic press.

Die forging: it is formed by using a mold on a die forging hammer or hot die forging press.

Ring grinding: refers to produce ring parts with various diameters by special equipment ring grinding machine, which is also used to produce wheel shaped parts, such as automobile hub and train wheel.

Special forging: including roll forging, cross wedge rolling, radial forging, liquid die forging and other forging methods, suiting for production of some special shape parts.

Process flow: forging billet heating → roll forging preparation → die forging forming → trimming → punching → correction → intermediate inspection → forging heat treatment → cleaning → correction → inspection.

Characteristic of technique:

(1). The forging part can bear a high impact load due to its higher quality than castings. Besides, its plasticity, toughness and the mechanical property of other aspects is greater than that of castings and rolled pieces.

(2). Material saving and shortens the processing time.

(3). High production efficiency.

(4). Free forging suits single unit or low volume production with high flexibility.

Application:

Roll and herringbone gear of large steel rolling mill, rotor, impeller and retaining ring of steam turbine generator unit, huge hydraulic press cylinder and column, locomotive shaft, crankshaft and connecting rod of automobile and tractor, etc.

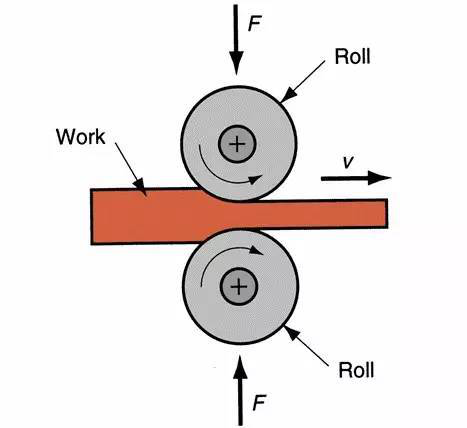

2. Rolling

Rolling: it is a pressure processing method that the metal blank passes through the gap (various shapes) of a pair of rotating rollers, and the material section is reduced and the length is increased due to the compression forming rolling of the rollers.

Rolling classification:

According to the movement of rolled pieces, it can be divided into longitudinal rolling, transverse rolling and cross rolling.

Longitudinal rolling: the process in which metal passes between two rolls with opposite rotation directions, and causes plastic deformation between them.

Cross rolling: the movement direction of the rolled piece after deformation is consistent with the direction of the roll axis.

Cross rolling: the rolled piece moves spirally, and the axis of the rolled piece and the roll is not at a special angle.

Process procedure:

Application:

Mainly used in the meal material profile, plate, pipes, and some non metal materials, such as the plastic products and glass products.

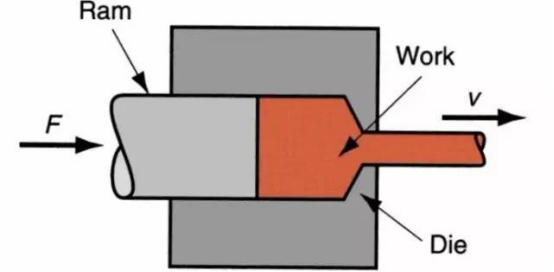

3. extrusion

Extrusion: the blank is extruded from the hole or gap of the die under the action of three-dimensional uneven compressive stress, so the the cross-sectional area is reduced and the length is increased. This processing method is called extrusion and this processing of the blank is called extrusion forming.

Process procedure:

Preparation before extrusion → casting bar heating → extrusion → stretching, twisting and straightening → sawing (sizing) → sampling and inspection → artificial aging → packaging and warehousing

Advantages:

(1). Wide production range, products specification, and variety.

(2). Flexible production, suiting for low volume production.

(3). High product dimension accuracy with good surface quality.

(4). Low equipment investment. Small factory area. Automatic production is easily achieved.

Disadvantages:

(1). Large loss of geometric waste.

(2). Liquid metal flow unevenly.

(3). Low extrusion speed, long auxiliary operation time.

(4). Large tool loss with high cost.

Wide production range, mainly suits manufacturing long rod, deep hole, thin wall and special-shaped section parts.

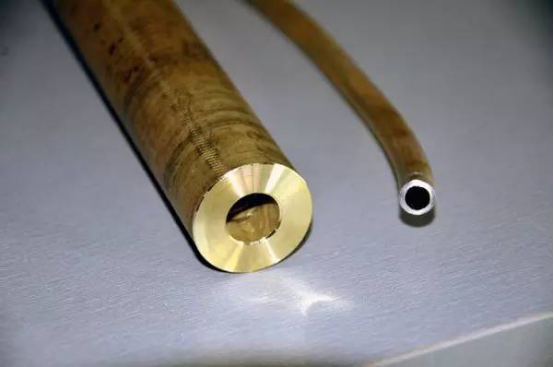

4.Drawing

Drawing: a plastic processing method in which an external force acts on the front end of the metal to be drawn to pull the metal blank out of the mold hole smaller than the cross-section of the blank to obtain products in same shape and size.

Advantages:

(1). Accuracy dimension with smooth surface.

(2). Tools with simple equipment.

(3). Continual producing long products at a high speed production with small cross section.

Disadvantages:

(1). The total deformation between pass deformation and two annealing is limited

(2). The length is limited.

Application range: drawing is the only method for processing the metal pipes, bars, sections and wires.

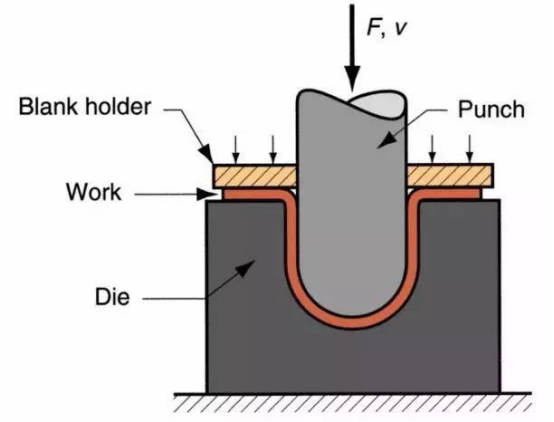

5. stamping

Stamping: works by pressure machine and mold to lay high pressure on the plate, strip, pipe, profile, and other materials to make it produce plasticity deformation or separate to obtain the parts with required shapes and sizes.

Characteristics of technique:

(1). High weight and high rigidity products can be obtained.

(2). Good productive, suiting for large volume production with low cost.

(3). Products with consistent quality can be obtained.

(4). High material utility rate. Good shearability and recoverability.

Application range:

Among all the steel material in the world, 60-70 percent of them are plate, and most of them are being stamped, such as the automobile body, chassis, oil tank, radiator, boiler drum, container shell, iron core silicon steel sheet of motor and electrical appliance. Moreover, the stamping parts are also involved in the instruments, household appliances, bicycles, office machinery, household utensils and other products.

Machine processing

Machine processing. In the production, the tools are used directly to cut the extra metal layer on the blank to make it in align with the size accuracy, shape, and positions on drawing. Besides, it also has a high requirement in terms of the corresponding accuracy and surface quality.

Common machine processing methods

Main processing range of the common mechanical machining method

| Method | Turnning | Milling | chipping | Drilling | boring | grinding | gear machining | CNC |

| machining shape | Revolving surface | plane | large plane | Inner revolving surface | largeInner revolving surface | fine machining all surfaces | Involute profile | surfaces with complex shapes and high accuracy |

| Tool | turning tool | milling tool | chipping tool | drilling head | boring tool | grinding wheel | gear machining tool | CNC tool |

| Equipment | lathe | Milling machine | chipping machine | drilling machine | boring machine | grindingmachine | gear machining machine | CNC machine |

Welding

Welding: welding is a manufacturing technology which works through methods of heating, high temperature or pressure to connect alloys or other thermal ductile material, such as plastic.

powder metallurgy

powder metallurgy is a processing technology which utilizes the metal or metal powder(or the mixture of the metal powder and non metal powder) as the raw material to produce metal material, compound material, and other types of products through forming and sintering.

Advantages:

(1). Most refractory metals and their compounds, pseudoalloys and porous materials can only be made by powder metallurgy.

(2). Metal saving and reduce the products cost.

(3). Won’t pollute material. High purity materials manufacturing is available.

(4). Powder metallurgy can ensure the correctiveness and uniformity of the ingredient proportion of material.

(5). Powder metallurgy suits for products in the same production line and large numbers, which reduces the cost largely.

Disadvantage:

(1). The size of the parts should be considered if it is not mass production.

(2). The fee for mold is higher than the cost of mold casting.

Production application range:

Powder metallurgy can produce porous, semi dense or fully dense materials and products, such as oil bearing, gear, cam, guide rod, cutter, etc.Powder metallurgy can produce porous, semi dense or fully dense materials and products, such as oil bearing, gear, cam, guide rod, cutter, etc.

Metal injection molding

Metal injection molding, simply known as MIM, which is a molding method that injects the plasticized mixture of metal powder and its binder into the models. It mixes the selected powder and binder first and then the shape required for granulating the mixture and then injection molding.

MIM process procedure:

MIM is divided into four special processing steps (mixing, forming, degreasing and sintering) to achieve the production of the parts. Deciding whether the products need surface treatment according to its properties.

Characteristic of technique:

(1). One time forming.

(2). Good surface quality, low scrapping rate, high production rate, easy to achieve automation.

(3). Low request to mold material.

Technique key:

Binder is the key of the MIM technology, of which the flowability of powder is enhanced only by adding a certain amount of binder to fit for the injection molding and the maintenance of the basic shape of the blank.

Semi solid metal forming

Semi solid metal forming which utilizes the semi-solid metals, simply known as SSM, to control the quality of the castings by its unique rheological and stirring properties.

Semi solid forming can be divided into rheological forming and thixotropic forming.

Characteristic of technique:

(1). Reduce the liquid molding defects and increase the quality and reliability.

(2). The molding temperature is lower than that of the all liquid molding, which reduces the thermal impact to the molds.

(3). Can produce alloys that cannot made by regular liquid molding method.

Application:

So far, it has been successfully used in the manufacturing of master cylinder, steering system parts, rocker arm, engine piston, wheel hub, transmission system parts, fuel system parts, air conditioning parts and other aspects of aviation, electronics and consumer goods.

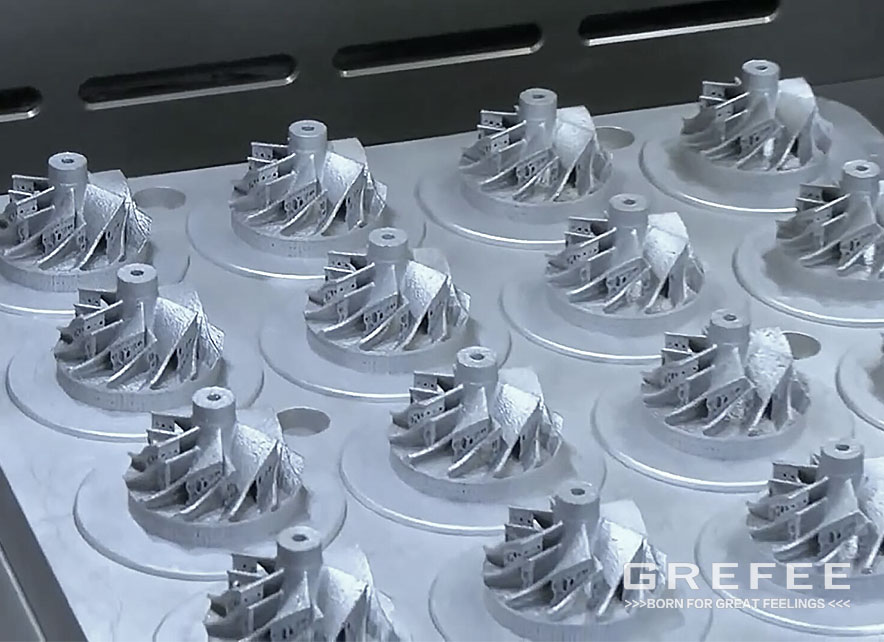

3D printing

3D printing is a rapid forming technology, which is based on the digital model files, and adopts powder metal or plastic and other bindable material to construct items through the way of printing layer by layer.

Comparison of 3D printing technology:

| FDM melt extrusion | SLA stereolithography | SLSSelective laser sintering | 3DPThree dimensional printing |

| Material | Wax, ABS, PC, PPSF, nylon, PLA and other thermoplasticity material, feed in filaments | Liquid photosensitive resin | Extensive range of material, thermoplasticity material, resin coated sand(coated sand), Polycarbonate, metal powder, ceramic powder | metal powder, ceramic powder |

| Mode | Melt extrusion molding | UV irradiation(wave length x=325mm, strength w=30mw) to achieve photopolymerization and curing | High strength CO2 laser sintering forming | Micro drop spray adhesive molding (silicone rubber) |

| Thickness accuracy | 0.15~0.4mm | 0.016~0.15mm | 0.08~0.15mm | 0.013~0.1mm |

| support | “Yes” if necessary | Yes | No | No |

| characteristic | Easy to use and maintain, low cost, and most widely used at desktop level | The method with the highest accuracy so far. | Mostly used in large-scale structural design, such as aerospace | High speed multicolor forming |

MORE BOLG

Categories

Latest blog

Try GREFEE now,for free

We keep your uploaded files confidential and secure.