Die casting technology supported 5G products

Posted on : February 14, 2022 By GREFEE

The development of 5G brings new requirements for the internet infrastructure. The number of its base and cost is over two times that of 4G. According to the reports, mobile terminal, automobiles, industrial internet, medical health, entertainment, five major developed industries will be benefited in advance.

The high demand of 5G communication bases and wave filters also stimulate the die casting suppliers of the whole industrial chain. The parts that are boosted by it include the development of cavity of the wave filters and the radiator box.

The increment of the wave filter designing complexity and numbers is a necessary tendency and the value and sales volumes will be increased dramatically. GRefee has put our foot in 5G market since 2016.

Our team has undertaken a deep research about the requirements, die casting molds, CNC processing and surface management of 5G products and has draw a comprehensive manufacturing standards of 5G production.

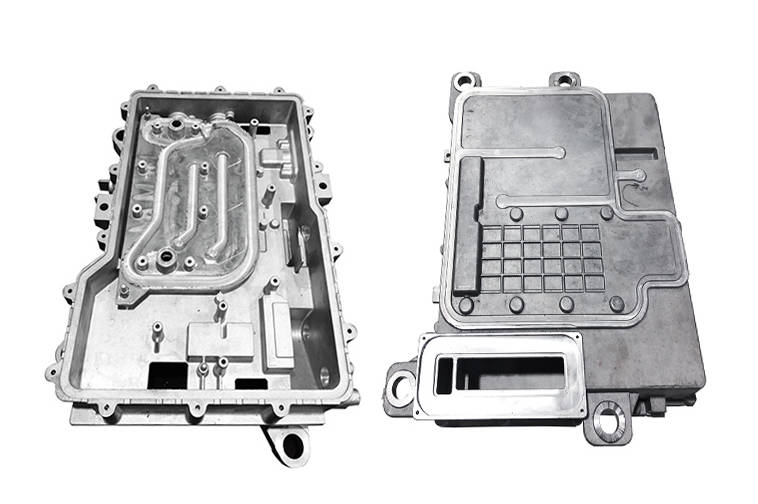

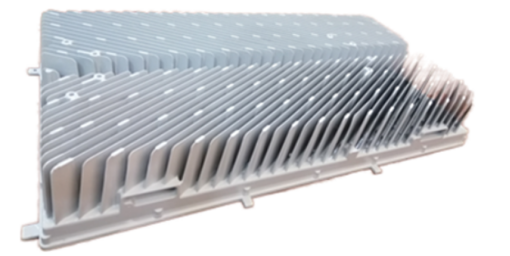

5G Communication Radiator Box

The radiator box applies the technology of Rheo-diecasting of Semi-solid Aluminum Alloys : dimensions of radiator cavity: 903MM×445mm, high thermal conductivity, thermal conductivity rate: 175W/m.k (regular die casting 130W/m.K), die casting heat sink: 100mm high, small end thickness0.8mm, single draft side sloping angle 0.8°).

Besides, in order to achieve better thermal capacity, the heat sinks are also increasing and tend to be thiner. Grefee is equipped with advanced die casting technologies which allow us to produce products whose height over 100mm and be thin as even 0.6mm or more.

Such products need to pay attention to the unstable die casting parts dimensions due to the uneven or unsuitable temperature in the manufacturing process of die casting.

During the process, defects might happen during the process including the ejector casting getting distorted, hot press generation, dip molding, sags on the surface, internal shrinkage or thermal bubble, etc.

When the mold temperature difference is big, it will exert an influence to some extent on the data in the production cycle, such as filling time, cooling time, coating time,etc. Besides, the service life of molds will also be affected due to the impact under the too hot or too cold conditions, which then lead to the expensive steel materials cracking.

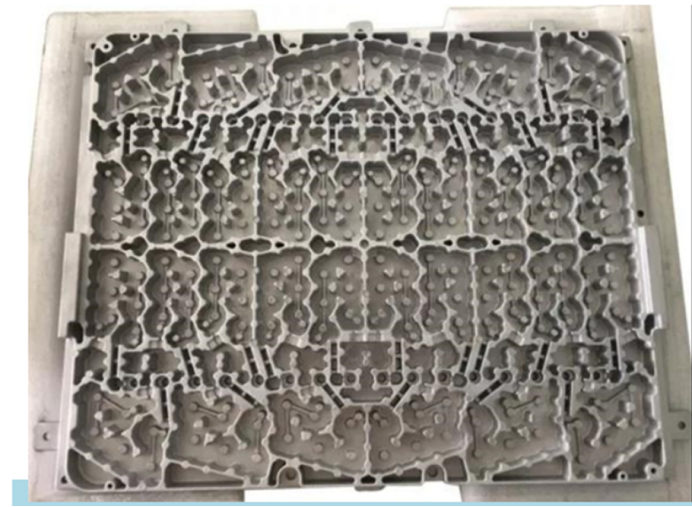

Communication base wave filter assembly parts

Communication base wave filter assembly parts are the critical components of the RF system. It mainly works by bypassing the specific frequency pro-potion of the sending and receiving signals and reducing its frequency proportion largely.

In the area of 3G/4G, the metal coaxial cavity has been the choice by the mainstream in the market due to its advantages of low-cost, mature technologies.

The wall thickness of die casting rough embryo products is 2.8mm and the filling length is 340mm. Many pillars inside the cavity are without connection and support.

It is easy to be distorted if the wall thickness of large parts is too thin. The die casting rough embryo products has requirements of complicated products structures, small space. It also has higher requirements on parameters as well as the precision, polish, surface hardness of the mold products.

In the domain of base station filter, the cavity filter is always the first choice of each base. With the continuous breakthroughs of Dielectric filter, it is aimed to develop more dielectric filter featured by small loss, small size, and high quality factor in the future.

Grefee’s die casting technological team will set heat balance temperature and minimize the tolerance of temperature to make it stable so that the die casting molds will remain in the standard die casting temperature range.

The liquid will fill out the die casting mold cavities according to the design requirements to produce product with clean surface, clean outline, and high quality.

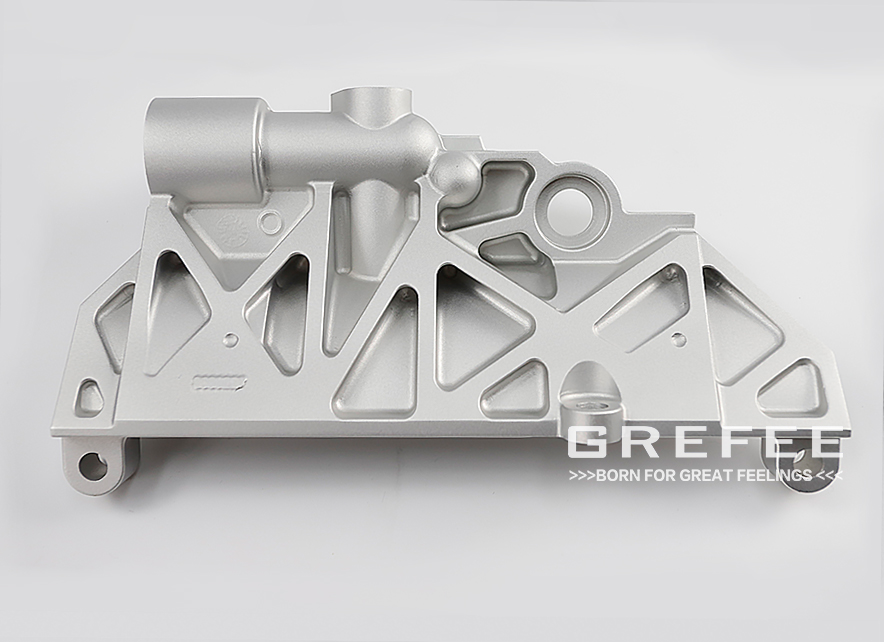

The die casting industries is turning into intellectualized

As the 5G is coming, which deeply stimulates the fulfillment and spread of the intellectual die casting factories, intelligent manufacturing has been the new method to improve enterprise management, develop emerging markets and achieve comprehensive transformation.

As the production requirement of 5G products is higher, the quality guarantee and production efficiency have to be matched with the die casting automotive manufacturing program and to replace the traditional manual work.

In the model construe of the production of automotive die casting, intelligent die casting is our cutting edge, which indicates that we aim to seize opportunities and own a large market share earlier in the continuous competitive market.

New demands in 3C industry represented by 5G, including new applications, such as automobile structural parts, new energy vehicles, building formwork, self-solid, squeeze casting and other new manufacturing technologies, digitalize automation, intelligent new technologies have influenced this industry positively and deeply.

It is full of both challenges and opportunities. In 2022, our die casting exhibition will be updated with “efficient die casting production with digitalized allocation and intellectual development as our main improvement. We are also going to continue leading the whole industry to move forward.

Try GREFEE now,for free

We keep your uploaded files confidential and secure.