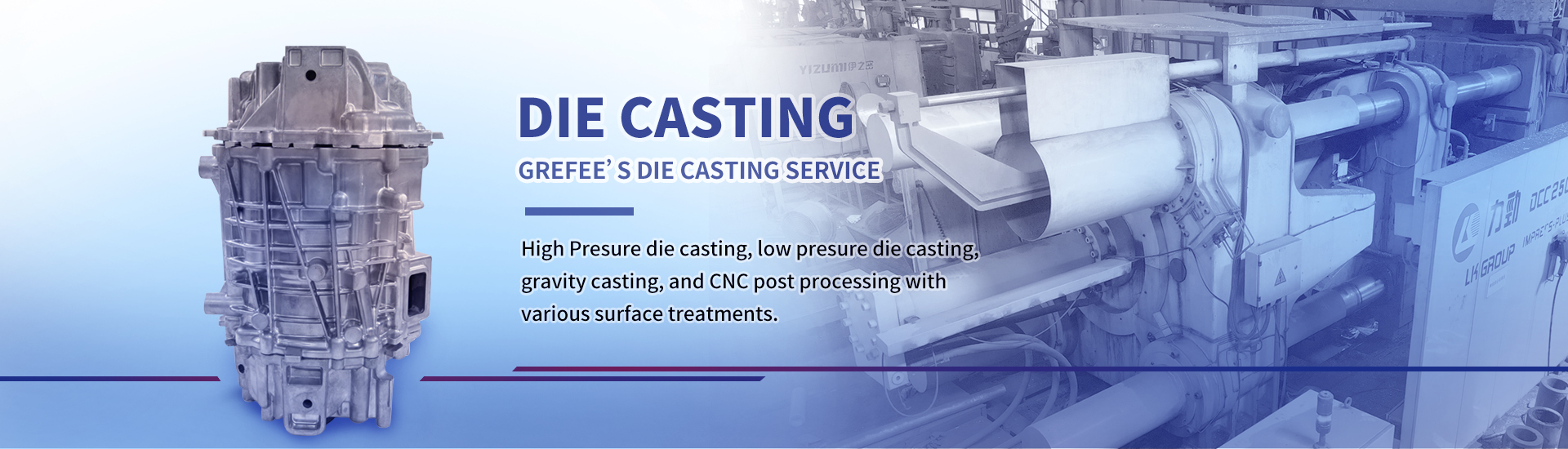

GREFEE’s Die Casting Service

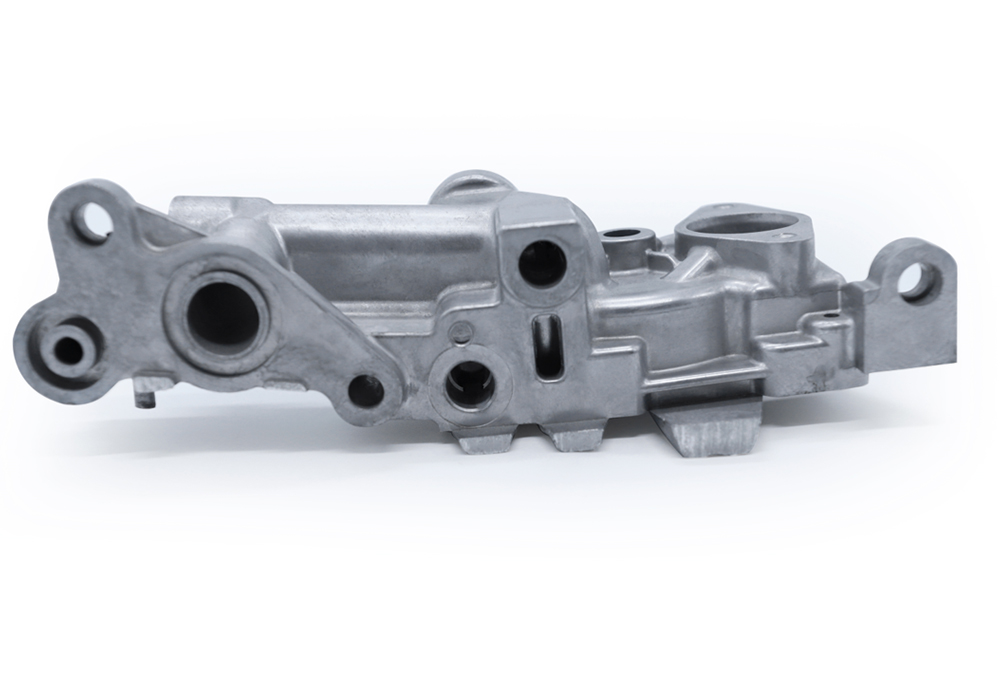

GREFEE has been focusing on the die-casting industry for 15 years. We have developed into a large-scale die-casting company integrating mold design, mold manufacturing, die-casting production, CNC machining, surface treatment, and assembly. The production capacity of plus products; the business covers many countries and regions in Asia, Europe, North America and so on. We specialize in providing die casting service of aluminum alloy, zinc alloy, magnesium alloy. Our team is particularly good at the manufacture of deep cavity products, high rib products, thin wall products, and high precision and complex products. Experience our unbeatable prices and our professional services, and let us provide a free quote and DFM assessment for your project.

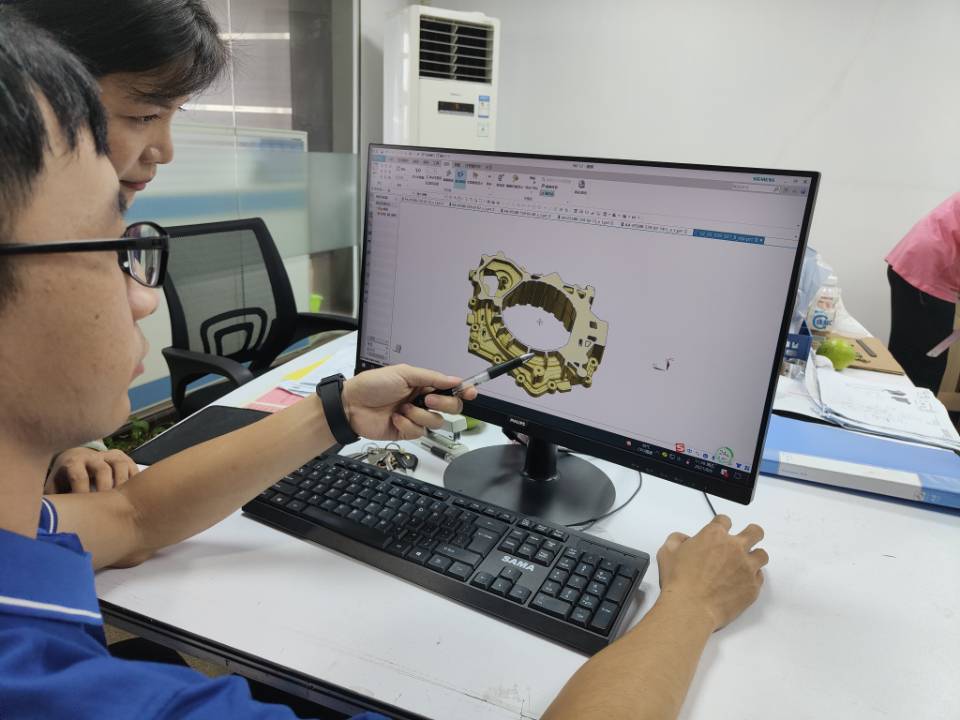

Powerful technical team provide you best die casting solution

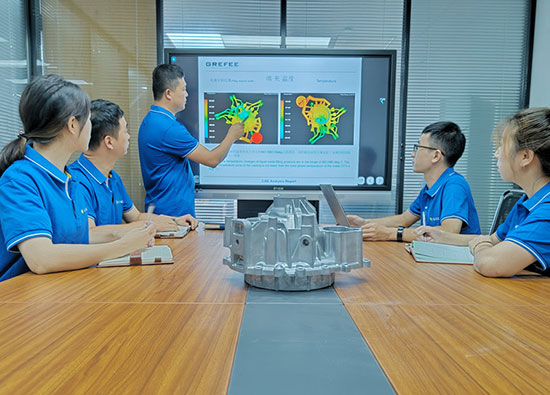

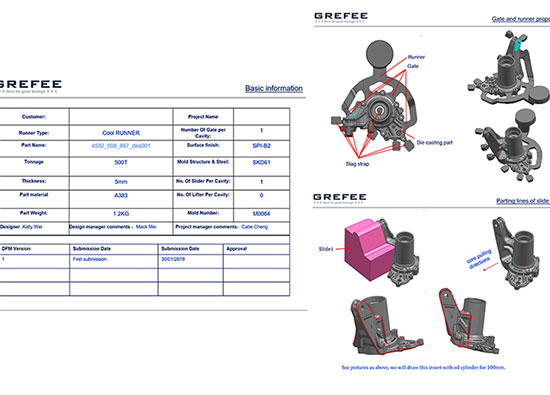

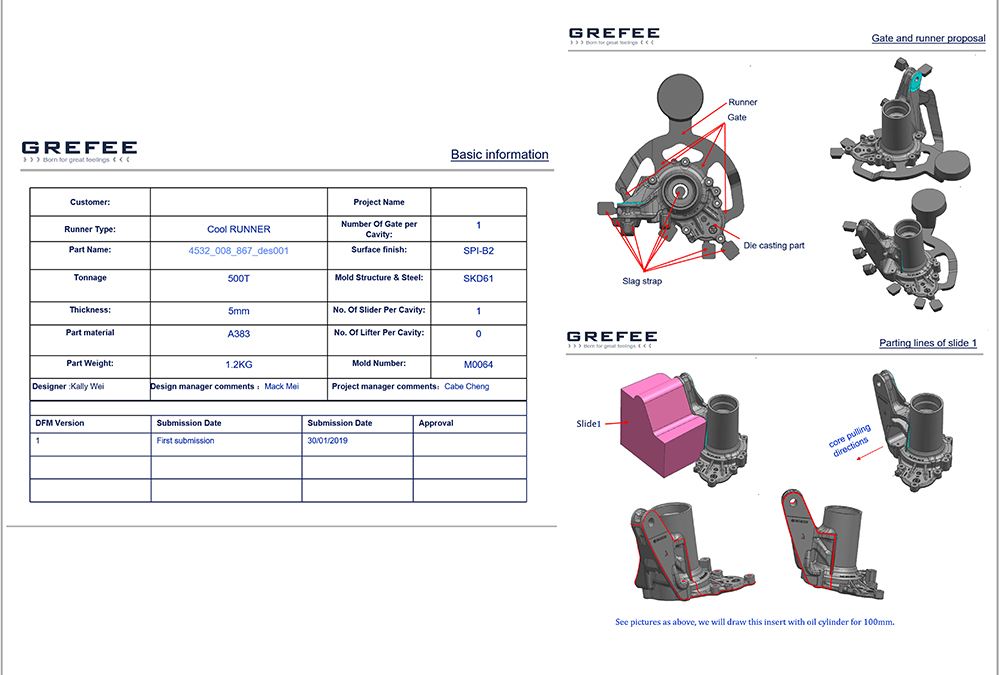

- Based on experience, we will give you appropriate suggestions for product structure and thickness, assist you to amend drawings and die casting blank drawings, then offer detailed DFM analysis for your confirmation.

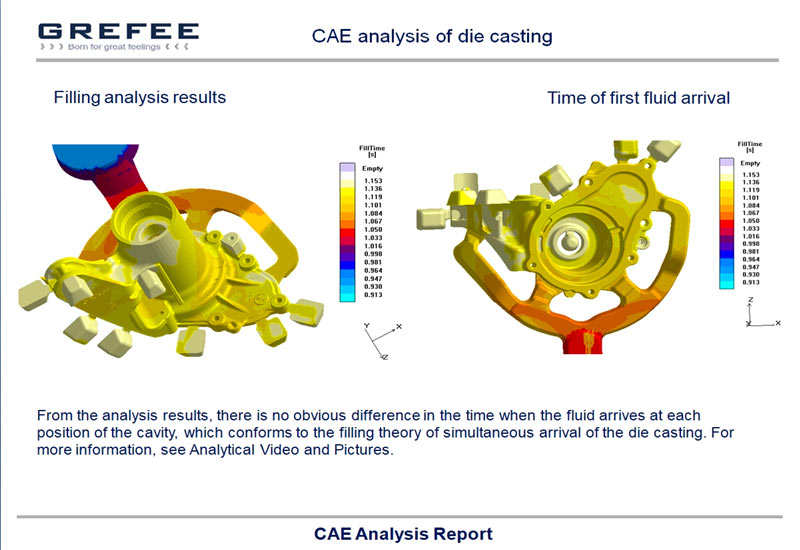

- GREFEE’s engineering team can make mold flow analysis, and design the most appropriate runner system and mould structure combineing the result of mold flow analysis, to ensure high quality of die casting mould and product.

- Organize appraisal meetings, related engineers and technical directors will make comprehensive feasibility assessments of product design, DFM analysis, mould flow analysis, mould structure, mould manufacture, die casting production, product CNC machining, surface treatment, packing and delivery. Finally we’ll feed back the meeting results to our clients.

Die casting mould

- 1.DMF&Mold flow

- 2.Offer 2D/3D mould drawing

- 3.Design Validation

- 4.Validate by GREFEE “check list “

- 5.Control by “action plan “

- 6.Validate by customer

- 7.Steel Ordering

- 8.Approval to order steel

- 9.Approval to start molding

We can provide free servies of DFM&mold flow and also assist you with the design of die casting blank products.

Better understand GREFEE Die Casting

GREFEE provides high-quality die casting moulds and die casting products, and also precision machining options and surface treatment.

Maximum machine 3500T

One-stop manufacturing service

Powerful technical team

Demanding

Specifications

Full dimension QC report

16ys+ industry experience

- GREFEE has 16 die casting machines(100T-3500T), 1 central grate producer(20²), and around 30 machines covering 3-axis, 4-axis, and 5-axis.

- GREFEE has 16ys die casting experience in auto industry, 5G communications industry, and LED industry.

- GREFEE is equipped with various testing machines, such as X-Ray machine, Spectrum material detection(Material certs- ingot, melt furnace and physical part), CMM, LEAK INSPECTION, NDT-LPINSPECTION….etc.

- Die cast products and control quality strictly follow standards of ISO9001 & TS16949.

- Provide free technical support, product amendment, DFM analysis, and MF analysis.

- Support small batch die casting production, and rapid prototype die casting.

Production Capacity

Our die-casting molds weigh up to 30T and the die casting products weigh up to 85kg, allowing us to provide ball blast, electroplating, powder spraying etc. out products have won numerous customers from different industries, like automotive, LED, 5G etc.

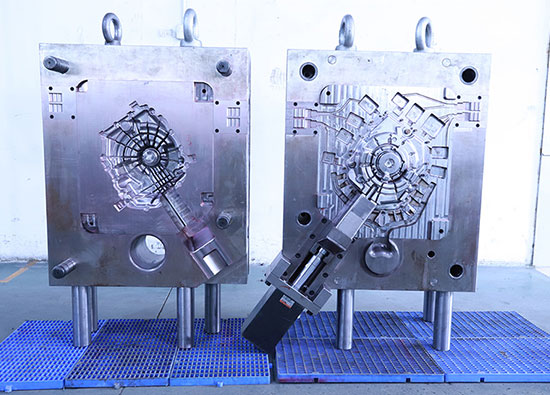

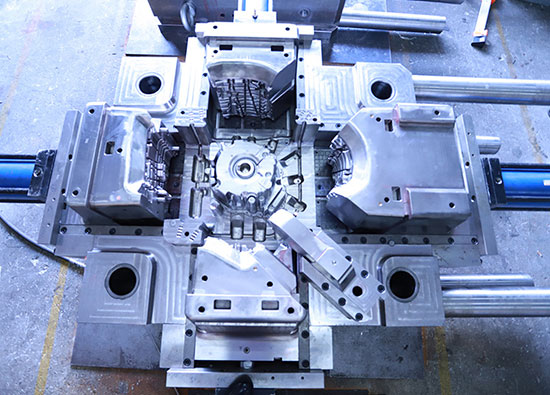

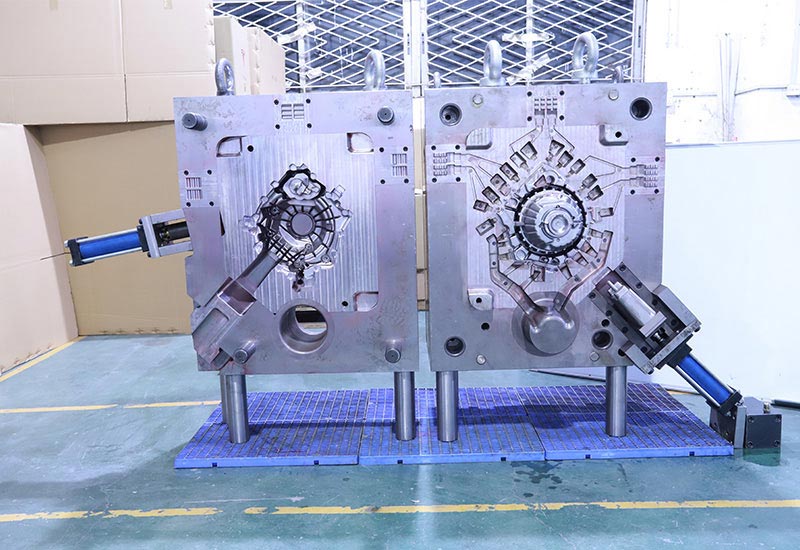

Die Casting Mould Manufacture

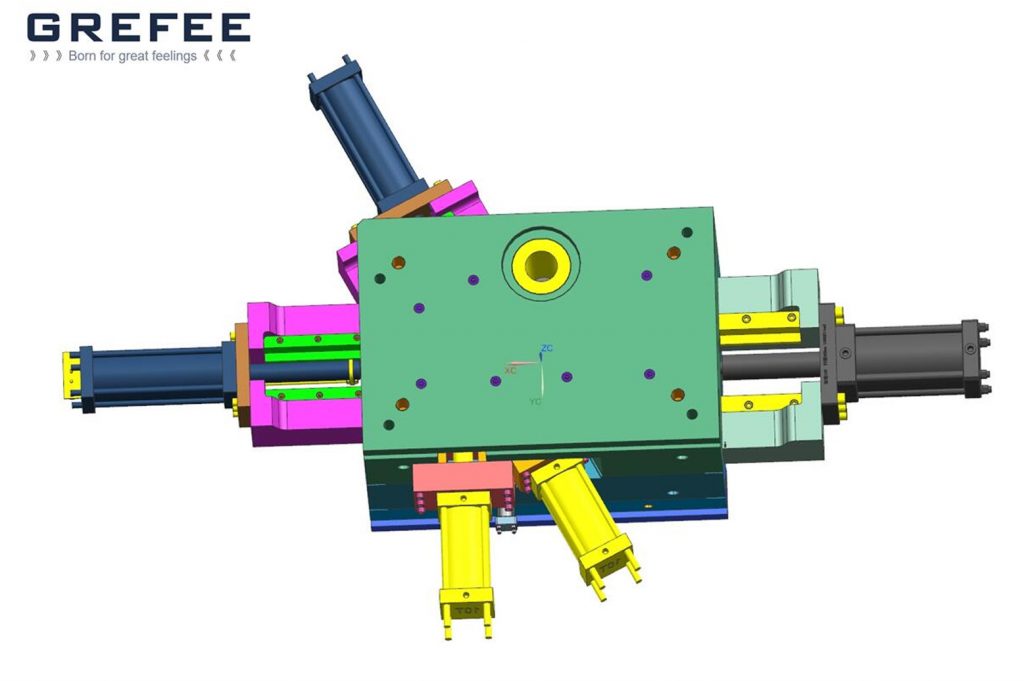

- GREFEE’s capabilities vary small-scale precision die casting moulds to large-scale automobile complicated die casting moulds to all kinds of die casting mould. Mould weight can up to 30 tons. Our exquisite manufacturing team and strict control procedures allow us to produce high quality moulds.

- GREFEE excels at designing, analyzing, and manufacturing moulds for automobiles and 5G communications equipment for example. We have rich experience

din automobile steering gears, gearboxes, new energy vehicle battery shells, and 5G RF devices(Radio frequency device) shells. - Based on GREFEE’s abundant experience in die casting, advanced equipment, professional manufacturing and quality control, as well as well-trained technical engineers, we can guarantee die casting moulds produced have a long-life, high stability, and high consistency throughout, thereby saving costs and achieving high quality and highly efficient manufacturing.

Die Casting

- High pressure die casting is one of the core businesses of GREFEE.

- GREFEE has 16 automatic die casting machines(100T-3500T), and are equipped with manipulator arms. Die casted products can be in various shapes of aluminum-zinc magnesium alloy, and their surface area from 1cm² to 81cm².

- Meanwhile, we’re equipped more than 200 CNC equipments(3-axis, 4-axis, and 5-axis), with maximum CNC machining size 2800MM.

- Every die casting machine is equipped with process control system, monitoring machine performance and ensuring consistency, and also assistant automation equipment.

- The core of flow is ISO 9001:2015 & IATF 94169 , which lays the foundation for high quality here at GREFFE.

GREFEE Die Casting Production Flow

The die casting industry has many tedious flows, and die casted products are more commonly used than other material products. We provide professional manufacturing services upon quotation, to save your time and cost, so we can achieve stable production and quality from design to T1 samples testing, with fast production and accurate control on lead time.Our professional experts team is always at your service, including innovation, design, prototyping, production, testing, checks and delivery.

Why Choose GREFEE for Plastic Die Casting

Whatever you need, whether its simple hardware insertion or complicated mechanical assembling, GREFEE can offer time-saving and cost-saving services for your project (die casting blank products).

✓Fast Delivery

Prototype mould completed within 1 week, production die casting mould completed in 2-5 weeks, and die casted products shipped in 1 week at the soonest.

✓Flexible Production Methods

Quantity of rapid prototype die casted parts can be 20pcs or less, you can also turn to massive die casting production, where 5,000pcs or more can be delivered each time.

✓Competitive Price

Based on GREFEE’s fully equipped production machines, manufacturing capability of complete die casting flow, and different dimensions of die casting mould base settings, can be shared using, we can fit customer’s mould inserts and achieve die casting production of unit part and multiple parts within 1 day.

✓Quality Assurance

Fully equipped with rounded testing machines, to guarantee reliable quality of die casting moulds and die casted products, and meet standards of ITAR & RoHS for all projects.

✓Excellent Post Machining Capabilities

Fully equipped with high precision machining machines, and many kinds of finishing

✓High Quality Service

Experienced technical engineers provide 1vs1 service

✓One-Stop Service

We assist your project from Prototype design , Die casting, CNC machining,Surface treatment, stock purchase, and assembling.

Die Casting Mould Types

Aluminum die casting

light weight, high cost-effective, recyclable, and solid. Die casted aluminum parts can be excellent geometrical shapes, commonly used in automobile and mechanical equipment industry. READ MORE

Zinc die casting

super long mould life, high precision dimensions, and various surface treatments. Die casted Zinc products give development advantages for your business. READ MORE

Magnesium die casting

lightest metal, high shock resistance, high strength, excellent thin-walled ability, ultrahigh liquidity, and good dimension stability. It can be die casted in net structure. READ MORE

Die Casting Resourcing

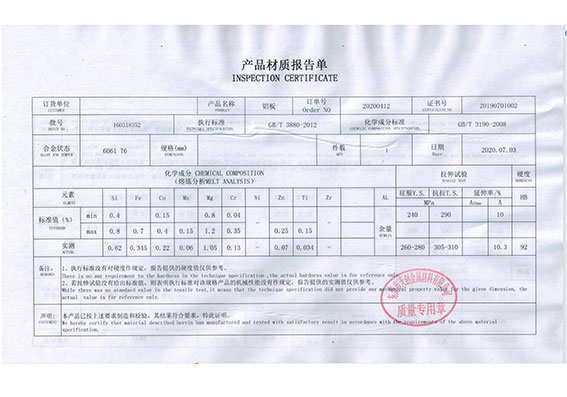

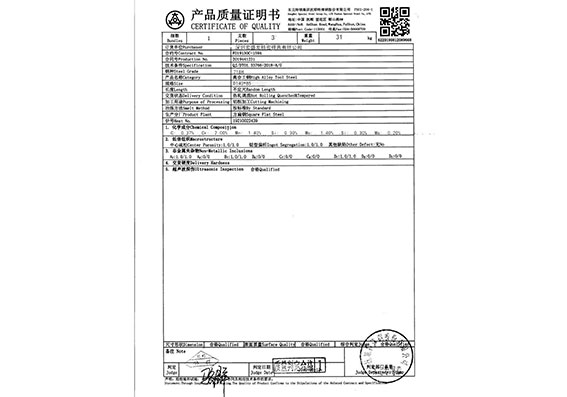

We have fixed raw material suppliers, whatever mould materials or die casting product materials, material certification material data sheet/COC/COA are available.

Die casting material

We have high-quality material supply channels, provide material certificates and low price advantages.

Die casted products quality

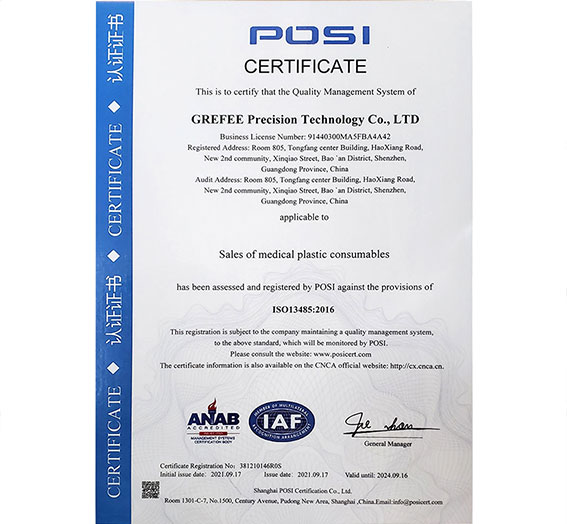

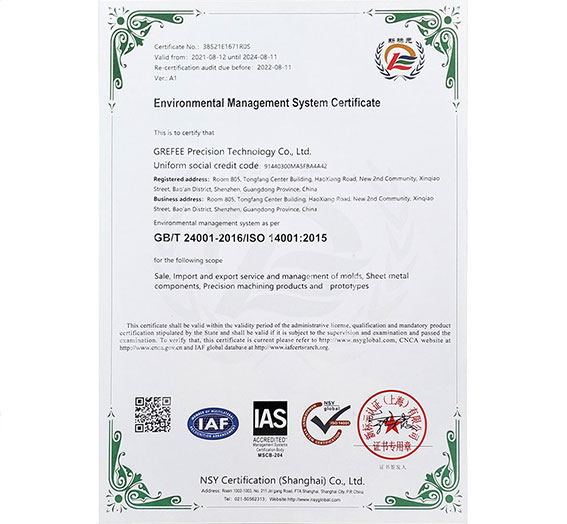

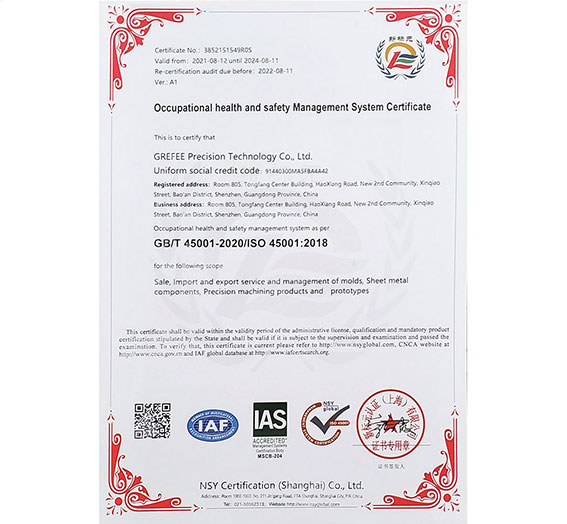

Strictly following standard of ISO9001,ISO13485,ISO16949,We have a variety of testing equipment to ensure quality.

Die casting design tips

With many years of industry design experience, familiar with the key design points of various industries.

Surface Treatment

Baking, powder coating, sand blasting, shot blasting, anodizing, hard anodizing, micro arc oxidation, electroplating, electrophoresis.

Product Color

GREFEE understands the importance of color to a product very well. We provide you with a wide range of color grading services using standard lighting conditions and colorimeters.

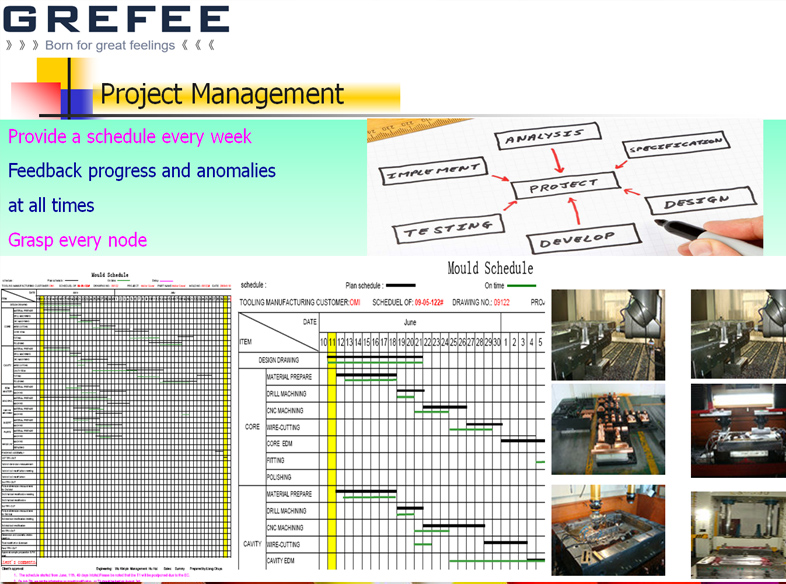

Project Management

How to satisfy customer demands and make sure all project successful? So our project management system is very important and effectivefrom RFQ to delivery.

Die casting service almost covers all industries

We specialize in manufacturing high-quality aluminum and Zinc die casting products, and also magnesium alloy. No matter its small-scaled or large-scaled production, our die casting service can provide you with a satisfying solution. You can trust our 16years of experience in the die casting industry, during which we gained extensive knowledge of the product development background, differences, and operating requirements of every industry, which is our unique advantage on suiting your specific needs.We produce products for overseas customers from all kinds of industries covering automobile, security, aerospace, electronic instruments, robotics, communication equipments, pump valves, LED …..etc.

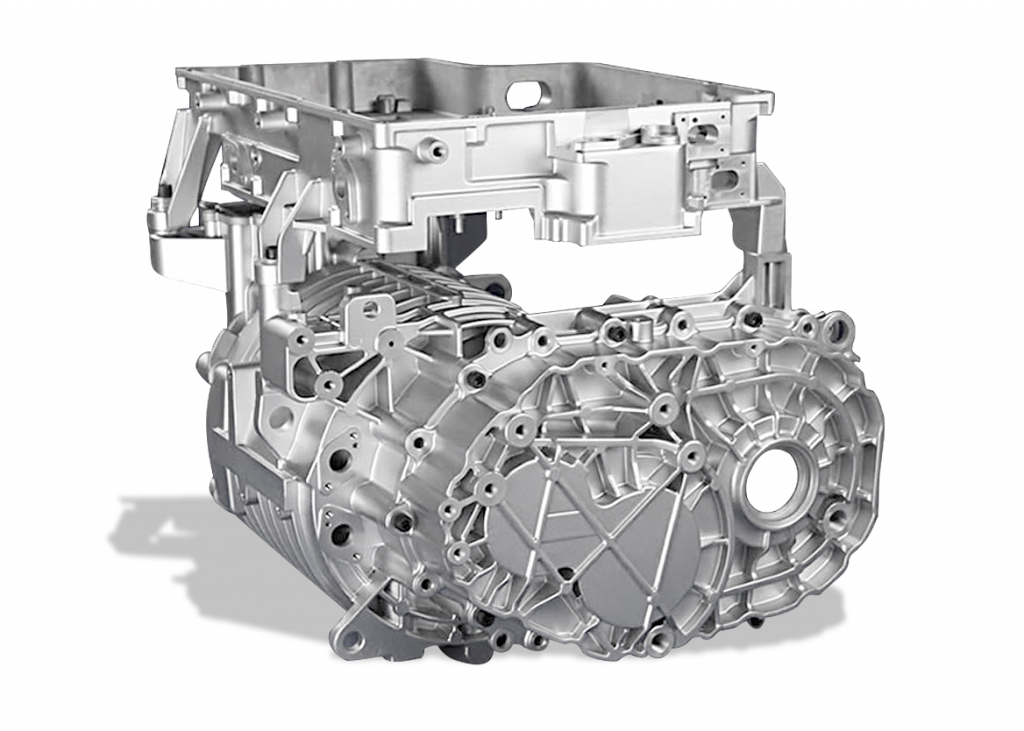

Automobile industry die casting

No matter its conventional fuel cars or new energy cars, I have plentiful experience in both. From the gearbox, uttering system, fuel tank, battery box, rear side member, to tower damping etc. To learn more information about die casting techniques in the automobile industry, please go to our blog section.

5G telecommunication die casting

5G telecommunication has been developing rapidly these days. GREFEE initiated the 5G market plan since 2012. Our 5G products, including the Communication Radiator Box, Communication base wave filter assembly parts have made great strides. We now have mastered vacuum die casting technology, semi-solid die casting technology and ultra-thin wall die casting technology.

Die Casting in LED industry

LED involves lightening applications and LED screens. Due to the needs of stage performance and outdoor advertising, LED screens have been put into large-scale production. LED die casting aluminum boxes have become the first choice for more and more customers because of its advantages of low cost, small size, convenient demounting, simple assembly etc.

Die casting industry

In the last 20 years, GREFEE has been the manufacturer of die casting products dozens of industries, including fire fighting, shipping, kitchen electronic applications, high precision electronics, smart-home appliances, bicycles, scooters, household electronic appliances, military equipment etc. Our annual die casting production for these different industries reaches 30 million tons.

Looking for a die casting manufacturer? Upload your files and get freequote!

See Our Past Projects

Die Casting Service For 5G products

The development of 5G brings new requirements for the internet infrastructure. The number of its bases and cost are over two times that of 4G. According to reports, mobile terminals, automobiles, industrial internet, medical health and entertainment are the five major developed industries which will benefit the most from these advances.

The high demand for 5G communication bases and wave filters also stimulate the die casting suppliers of the whole industrial chain. The parts that are boosted by it include the development of cavities of the wave filters and the radiator box. The steady increment of wave filter designing complexity and numbers is a necessary tendency and the value and sales volumes will be increased dramatically. GRefee has put our foot in the 5G market since 2016. READ MORE

Die Casting Service For New energy vehicle

With the proliferation of new energy cars, the automobile lightweight and integrated die

With the proliferation of new energy cars, the automobile lightweight and integrated die casting parts have increased, so companies who have existing experience in these two areas will benefit.

The area is affected by many factors, such as higher standards to the fuel vehicles’ fuel consumption, a higher subsidy threshold for e-bikes, and the pressure from store credits of electric cars. The complete vehicle and parts makers urgently need new technology and methods to achieve reduction and energy efficiency.READ MORE

Die casting case of automobile gearbox for Ford

Successful research and development in die casting moulds is part of a huge system engineering network which integrates with different technologies and resources together. These include raw materials, heat treatment, mould design, die casting technology, processing technology, assembly technology, production management and quality control, etc. A customized die casting solution is a very important part of the process, and the choice of technology directly affecting the part quality and its post production.

Automobile gearbox is the most critical part of the automobile transmission system. The gearbox shells usually have intricate complex structures, and are hard to manufacture. For these complicated die casted components, a good die casting design solution plays a decisive role in the product quality. This article will introduce the case in detail for Ford automobile gearboxes made by GREFEE. READ MORE

Die casting of LED products

These days, small spacing LED has quickly occupied the market. As the new focus and new driven force of the domestic LED screening industry, the rapid development of small spacing LED also benefits its peripheral products in the same way. One such the products is the LED die casting box.

The conventional iron box has many drawbacks, for instance, it is heavy and has low accuracy, etc. It is hard to fulfill the requirements of the requests for small spacing LED. Thus, that is why the new LED die casting box has appeared.

As a well-known LED die casting box manufacturer, GREFEE has a comprehensive system for LED die casting boxes and peripheral products, from development to manufacturing to assembly, etc. READ MORE

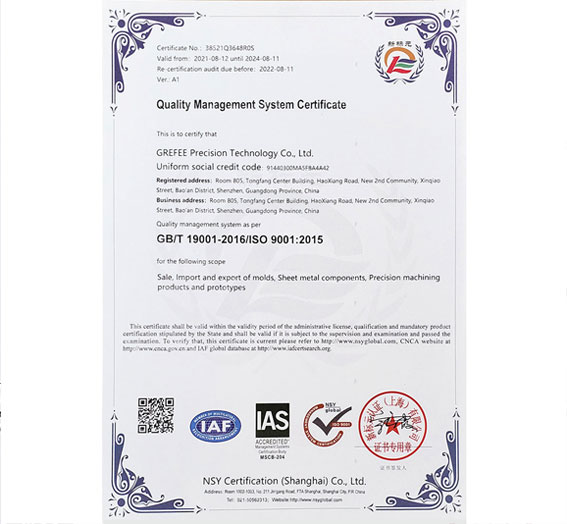

Quality assurance

GREFEE is certified with ISO900,TS16949,ISO14001,ISO45001 ISO27001 .We have high accuracy equipments like spectrum analyzers, material testing machines, X diagnostic machines, CT and profile measuring instruments, and three-coordinates measuring, to meet demands of component analysis, defect detecting, leakage testing and full-size measurement in die casted products.

We’re supported by powerful quality control systems and a quality management team of more than 40 distinguished QA engineers. Strictly following standards of ISO9001 /ISO13485/ISO16949, GREFEE’s control and management team are involved in the whole process, from product R&D, suppliers resourcing and auditing, material testing, manufacturing controlling, products checking, laboratory testing, delivery and after-sale.

We’re always working hard in meeting international standards, to make sure we provide better service for our clients all over the world.Upload your product design to get free and competitive free quote for die casting.

Get Your Die Casting Project Started Today

GREFEE produce not only die casting components, but also injection molding ones. Our skilled engineering team know your design goals very well, and are able to provide various suggestions, so we can make your parts fast and economically.We know how to adjust plastic or metal components to achieve perfect assembling, which will save you time and cost from the start.Upload your files and get technique support!