Causes analysis and improvement methods of strain in die casting products

Posted on : March 23, 2022 By GREFEE

To learn more problems and preventions of die casting, click to check it out.

What’s is the die casting strain?

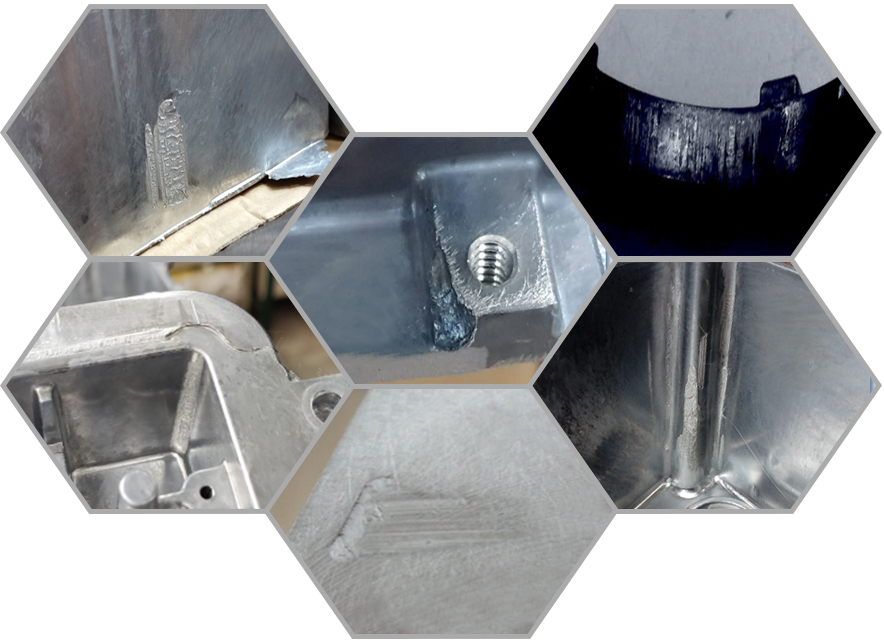

In the mold releasing, the die casing part will be ejected and will cause irregular patterns on the sidewall, which is called strain.

There are strains with a certain depth on the casting surface along the mold opening direction. severely, there are scars or cracks on one side.

Causes:

1. Die core, the angle of the mold wall is too small or inverted

2. indentation on die core and mold wall

3. aluminum alloys and zinc alloys sticking on the mold

4. the casting is inclined when it is ejected or the core axis is inclined

5. the wall is too rough

6. Mold release agent is often not painted on the area

7. Low iron content in aluminum alloy

8. too high pouring temp and mold temp

9. Improper pouring system directly impact the mold wall or mold core

10. Too high injection speed

11. Cavity surface is not nitrided

How to improve the problem of strain?

1. Products has bright marks without burrs after pull out – modify the mold to ensure the angle is enough for releasing the mold.

2. Galling or cracking – polishes the indentation, replacing mold or welding the mold wall

3. strain burrs – polishes mold

4. Large area strain on one side, abnormal sound in ejection – adjust the structure of mold

5. Multiple narrow strip shaped strain – polishes and grinds the surface

6. Mold surface temp is too high, uniform sticking to aluminum – mold release agent amount is thin and uniform, cannot miss the mold release agent.

7. Aluminum alloys sticking on the mold surface – increase the iron content to 0.6-0.8% appropriately

8. Aluminum alloys sticking on the mold surface, especially around the in-gate— decrease the pouring temp and control the mold temp within the process standardized range.

9. Server sticking problem of aluminum to the mold wall or die core – adjust the in-gate position and filling direction.

10. In-gate of the mold cavity is flushed seriously accompanied by the aluminum alloy sticking issue – decreases the speed properly.

11. The aluminum alloy is often stuck on the cavity surface – has to do surface nitriding

Key inspecting areas to die casting parts:

The die casting strain is often on the areas, like deep holes, side walls, corner, etc.

How does strain affect the product?

Strains on the surface of die casting aluminum alloys and die casting zinc alloys will affect the product appearance and the surface treatment on die casting surface. Besides, it also affects the hermetic seal of the product.

How to evaluate whether a die casting part with strain is qualified or not?

Mainly by visual after de-burrs or measured by eyes after painting the product would be easier.

1. Strains on product surface is unqualified.

2. Strains in the screw holes is unqualified because it will affect the posterior tooth shape of tapping

3. Strains inside the seal groove is not allowed, which affect its finish and make it unable to seal.

4. Non-baking paint side and cattily depth ≤0.1mm, try to grind and polish to see if can remove the strains.

5. Notify to modify. If it passed the post-treatment, it also needs to confirmed by die casting.

Improves the quality of your die casting parts

Strain is a common tricky problem and it is called one of ten tricky problems in the die casting industry. Even the smooth product might be scratched as well. The rough sides will be more likely to be scratched.

Once it comes to strain, many companies will boil it down to the draft angle is not big enough. So why do the products still have strains after increasing the draft angle? Appearance strain is not simply the problem of draft angle and is hard to deal with. Contact us for free scientific die casting production plans for you.

MORE BOLG

Insert mold in injection mold service

What are advantages and disadvantages of Zinc alloy and Aluminum alloy?

Inspection standards for injection molded partappearance

How to judge the quality of your plastic products?

Inspection standards for CNC machining

To ensure that your products are 100% qualified

Categories

Try GREFEE now,for free

We keep your uploaded files confidential and secure.