Causes analysis and improvement methods of discolored mottles in die casting

Posted on : March 23, 2022 By GREFEE

To learn more problems and preventions of die casting, click to check it out.

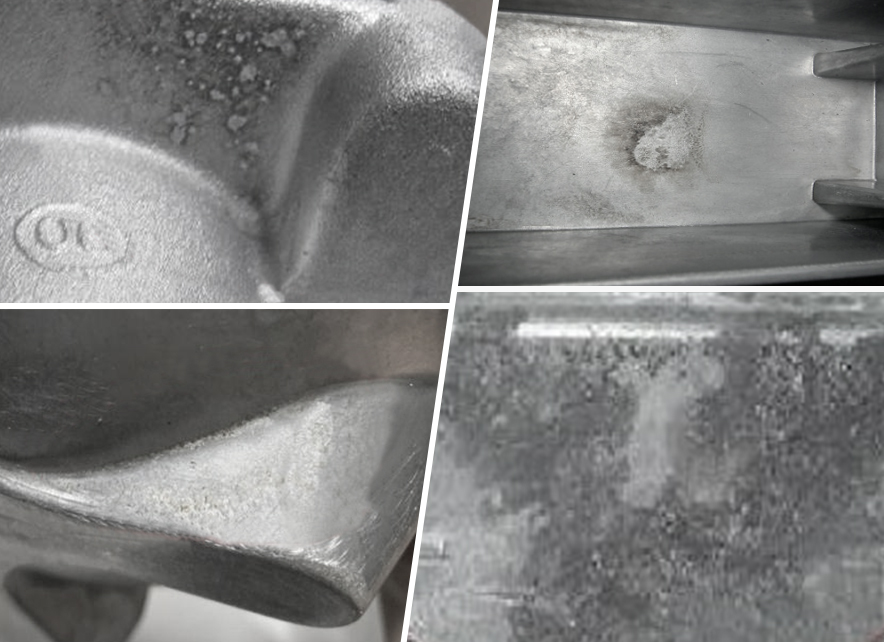

What are the discolored mottles on the die casting surface?

The die casting surface presents different colors which are inconsistent with that of the part body.

causes:

1.the mod release agent is not pure or too much

2.The graphite content is high in mold release agent.

3.After opening the mold, taking the part in spraying painting, or after spraying painting, which causes the mold release agent splashing on the casting surface.

4.Position of the punch oil spray and time are incorrect.

5.During the transportation, the water or oil splashed on casting surface.

How to improve the discolored mottle in die casting?

1.the colour of mottles is light. the mold release agent is thin and uniform, no stacking allowed. It should be dispersed evenly by the compressed air.

2.The color of mottles is black.- Reduces the graphite content in mold release agent, or picks stone free ink based release agent;

3.The color of mottles is light. After opening the mold, the spray painting must be operated before taking the part.

4.The color of mottles generally is dark red. The punch oil should be applied after releasing the parts, and should not be applied on the front end before the punch returning. The punch oil should not be sprayed into the gate directly.

5.the color of the mottles is not consistent. The color is light if it is mixed with water and dark red with oil splashes. The protective measurements must be guaranteed during the transportation between different procedures.

How do mottles affect the die casting products?

it mainly affects the appearance of products, or the followed electroplating painting technique.How to know whether a die casting part with discolored mottles is qualified or not?

How to know whether a die casting part with discolored mottles is qualified or not?

1. The area of discolored mottles should not exceed 1% gross area.

2. No discolored mottles on the just made product.

4. Can be removed by sanding.

how to improve the discolored mottles issue?

70% of discolored mottles are related to the mold release agent. By using the high-quality mold release agent and controlling the ratio, we can avoid this issue effectively.

GREFEE has 20 years of experience in die casting. High-precision die casting is a rigorous scientific production. GREFEE has a professional team providing free assessments for your project. Contact us now!

MORE BOLG

Insert mold in injection mold service

What are advantages and disadvantages of Zinc alloy and Aluminum alloy?

Inspection standards for injection molded partappearance

How to judge the quality of your plastic products?

Inspection standards for CNC machining

To ensure that your products are 100% qualified

Categories

Try GREFEE now,for free

We keep your uploaded files confidential and secure.